Cutting-off, steering and speed changing device for hygienic product production

A technology for shifting gears and sanitary products, applied in metal processing and other directions, it can solve the problems of poor surface line speed, large space occupation, and easy deviation of the fitting position, so as to achieve compact structure, high work efficiency and powerful functions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

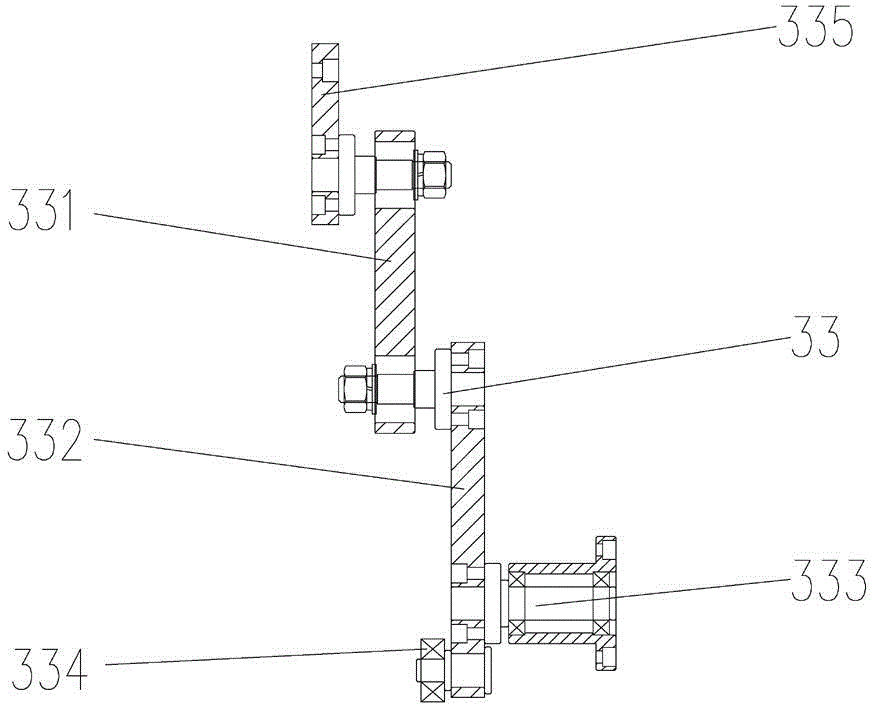

[0020] Such as Figure 1 to Figure 7 As shown, the present invention is used in the production of sanitary products to cut off the steering gear, including a frame 10, an adsorption mechanism 7, a cutting mechanism 1 for cutting off the elastic material adsorbed on the adsorption mechanism 7, and a device for turning the adsorption mechanism 7. The steering mechanism 2 and the speed change mechanism 3 used to change the speed of the adsorption mechanism 7, the cutting mechanism 1, the steering mechanism 2 and the speed change mechanism 3 are respectively fixed on the frame 10, and the frame 10 rotates and fixes a main shaft 4, and the outer eccentric sleeve of the main shaft 4 Provide a support sleeve 5 fixed on the frame 10, the support sleeve 5 and the main shaft 4 are eccentrically arranged, the support sleeve 5 is set outside the main shaft 4 through the bearing one 61, the support sleeve 5 is equipped with a bearing two 62, and the outer surface of the bearing two 62 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com