Silicon-free liquid shampoo and preparation method thereof

A technology of shampoo and vegetable oil, which is applied in the field of daily chemical cleaning products to achieve the effect of no tangle, full hair and good conditioning and nursing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

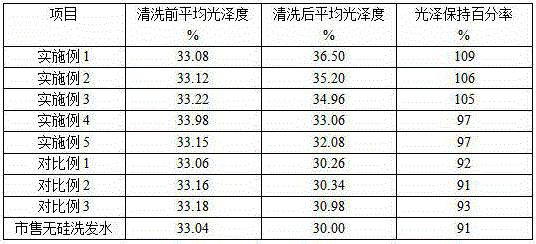

Examples

Embodiment 1

[0026] Embodiment 1, the silicone-free shampoo of the present invention and its preparation

[0027] Formula: 30g of inulin, 40g of vegetable oil (the weight ratio of almond oil to nut oil is 2:5), 15g of PEG-60 hydrogenated castor oil, 12g of PEG-120 methyl glucose dioleate, lauryl ether sulfate Sodium Ester 50g, Cocamidopropyl Betaine 60g, Alkyl Glucoside 20g, Sodium Cocoyl Glycinate 30g, Tetrasodium EDTA 2g, Citric Acid 2g, Preservatives (Phenoxyethanol and Methylisothiazoline The weight ratio of ketone is 9:1) 5g, essence 8g, water 726g.

[0028] Preparation: (1) Mix PEG-60 hydrogenated castor oil, vegetable oil and essence, stir evenly to obtain a mixture, set aside;

[0029] (2) Take 30% of the total weight of the components in water, add PEG-120 methyl glucose dioleate, raise the temperature to 70°C and stir until completely dissolved, continue to add 30% of the total weight of the components in water, and the temperature of the system drops to 55°C, add sodium laure...

Embodiment 2

[0032] Embodiment 2, the silicone-free shampoo of the present invention and its preparation

[0033] Recipe: 5g of inulin, 50g of vegetable oil (the weight ratio of almond oil to nut oil is 1:2), 20g of PEG-60 hydrogenated castor oil, 2g of PEG-120 methyl glucose dioleate, laureth sulfate Sodium ester 60g, cocamidopropyl betaine 30g, alkyl glucoside 50g, sodium cocoyl glycinate 10g, tetrasodium edetate 5g, citric acid 5g, preservatives (phenoxyethanol and methylisothiazoline The weight ratio of ketone is 9:1) 2g, essence 2g, water 759g.

[0034]Preparation: (1) Mix PEG-60 hydrogenated castor oil, vegetable oil and essence, stir evenly to obtain a mixture, set aside;

[0035] (2) Take 25% of the total weight of the components in water, add PEG-120 methyl glucose dioleate, raise the temperature to 75°C and stir until completely dissolved, continue to add 35% of the total weight of the components in water, and the temperature of the system drops to At 60°C, add sodium laureth...

Embodiment 3

[0038] Embodiment 3, the silicone-free shampoo of the present invention and its preparation

[0039] Recipe: 50g of inulin, 2g of vegetable oil (the weight ratio of almond oil to nut oil is 3:4), 2g of polysorbate-20, 20g of PEG-120 methyl glucose dioleate, lauryl ether sulfate Sodium ester 30g, cocamidopropyl betaine 80g, alkyl glucoside 10g, sodium cocoyl glycinate 50g, tetrasodium edetate 1g, citric acid 1g, preservatives (phenoxyethanol and methylisothiazoline The weight ratio of ketone is 9:1) 9g, essence 10g, water 735g.

[0040] Preparation: (1) Mix polysorbate-20, vegetable oil and essence, stir evenly to obtain a mixture, and set aside;

[0041] (2) Take 35% of the total weight of the components in water, add PEG-120 methyl glucose dioleate, heat up to 70°C and stir until completely dissolved, continue to add 25% of the total weight of the components in water, and the temperature of the system drops to 55°C, add sodium laureth sulfate, cocamidopropyl betaine, alky...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com