Two-shaft multi-port discharging feeder

A bait feeding machine and material feeding technology, which is applied in fish farming, application, animal husbandry, etc., can solve the problems of small feeding range, inability to meet work needs, and affect breeding efficiency, so as to ensure stable and continuous operation and save breeding cost and the effect of reducing the risk of farming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

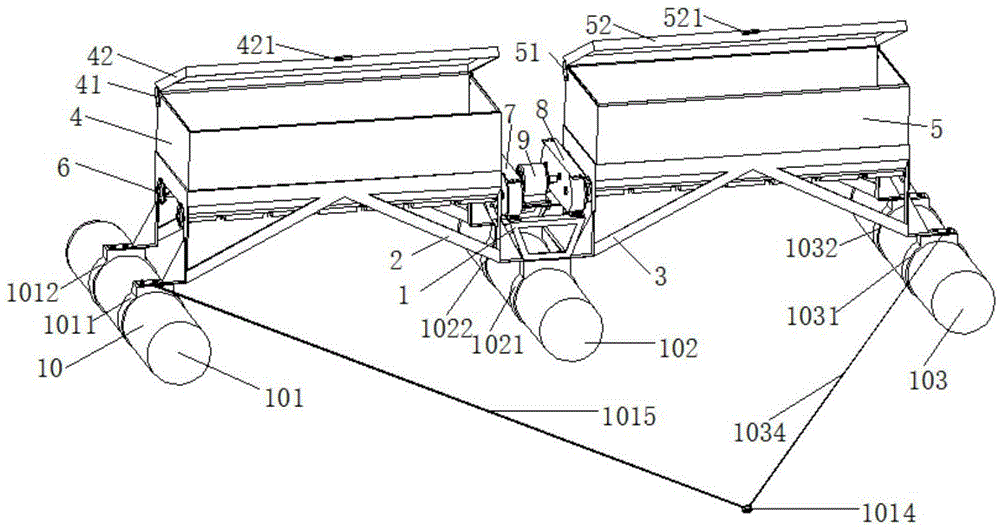

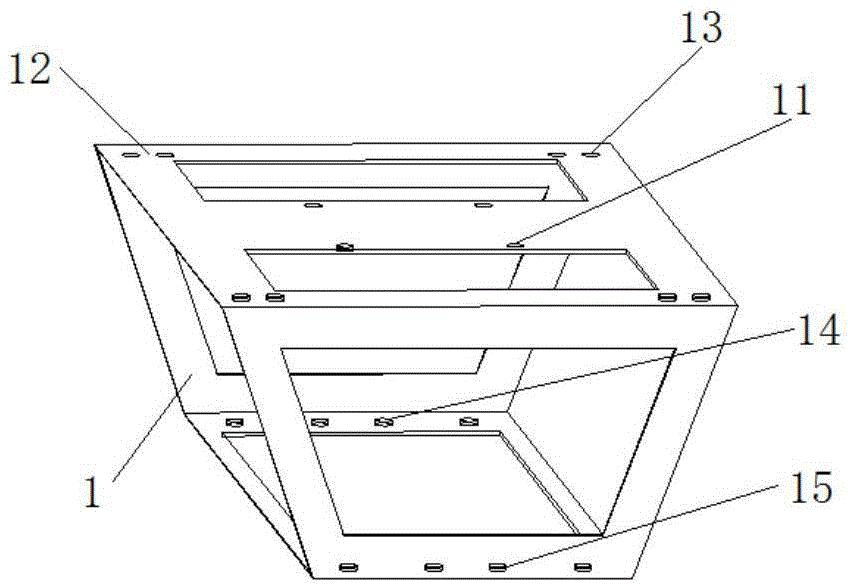

[0025] The biaxial multi-port blanking bait feeding machine of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 with Figure 9 , the biaxial multi-port blanking bait feeding machine of the invention comprises a middle frame (1), a left frame (2), a right frame (3), bait boxes (4, 5), a feeding mechanism (6), Single-input and double-output co-steering reducers (7, 8), feeding motors (9), floating bodies (10), and the bait boxes (4, 5) are arranged symmetrically with respect to the middle frame.

[0027] The bait box (4) is connected to the hopper cover (42) through a hinge (41), the hopper cover (42) is provided with a fixed handle (421), and there is a protrusion in the middle of the bottom of the bait box (4). Narrow and long plane (46), the narrow and long plane (46) fits with the flat strip (25) on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com