An automatic film transfer device and control method applied to semiconductor equipment

A control method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, transportation and packaging, electrical components, etc., can solve the problems of poor film transfer accuracy and low efficiency, and achieve improved efficiency, high efficiency, and reduced cavity size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

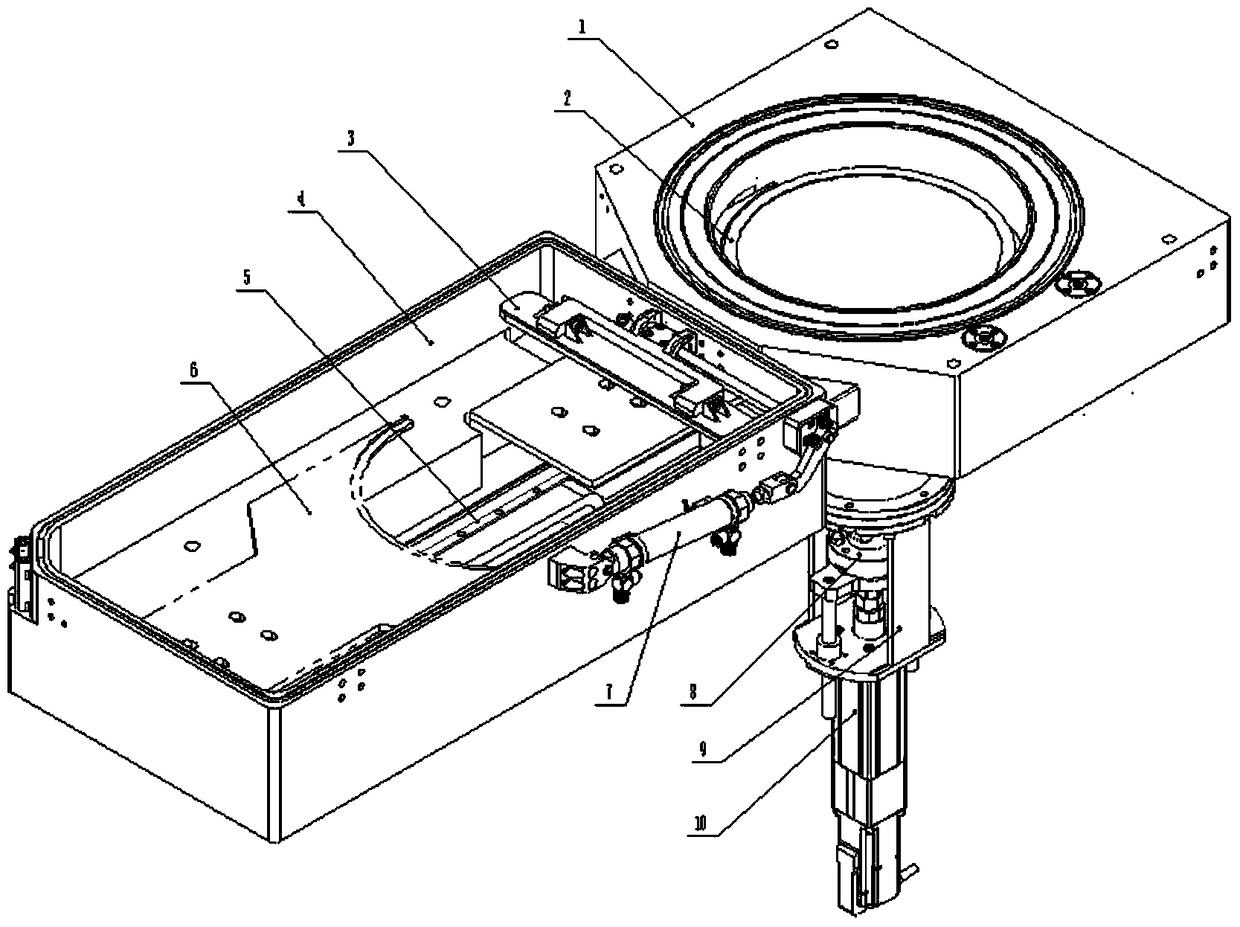

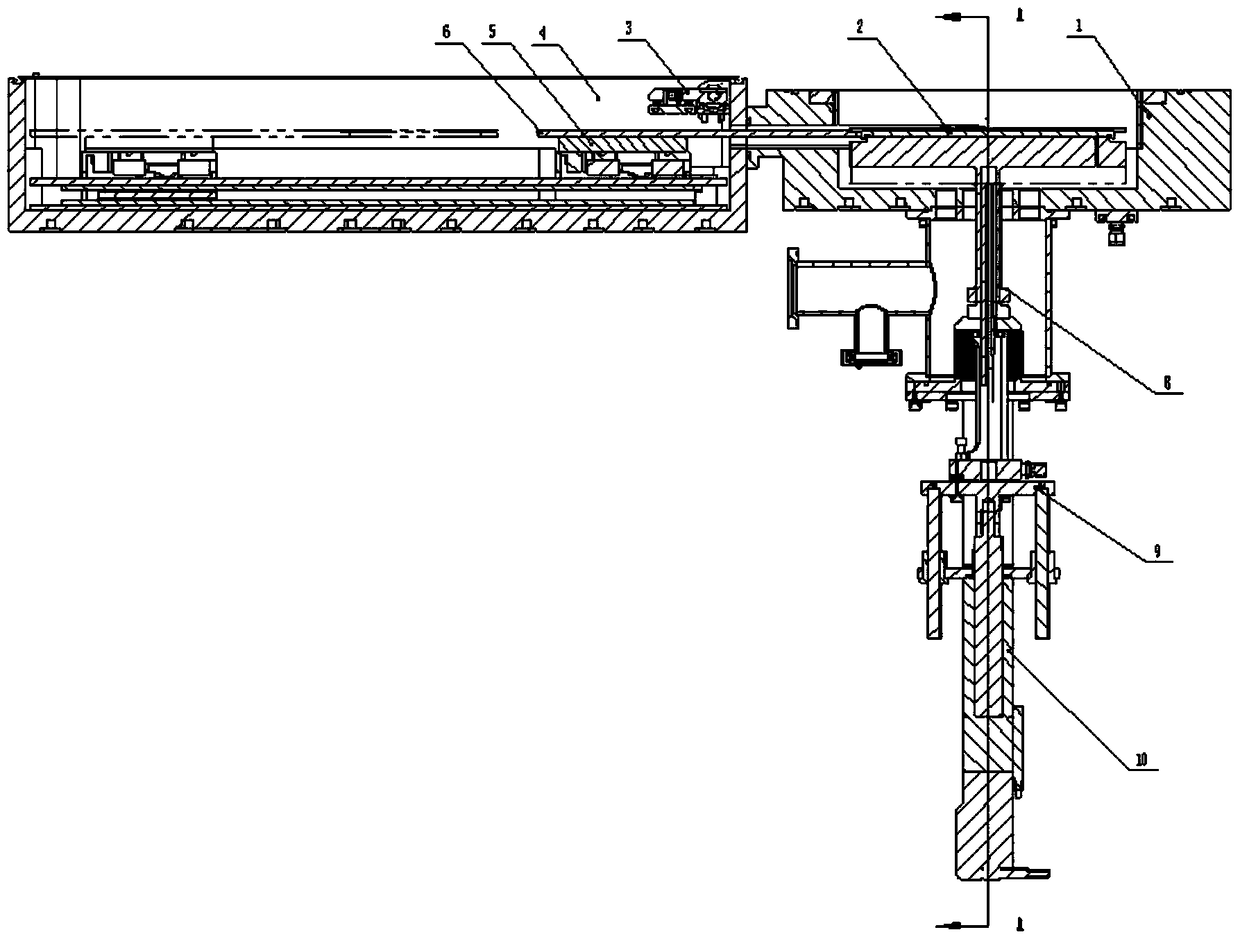

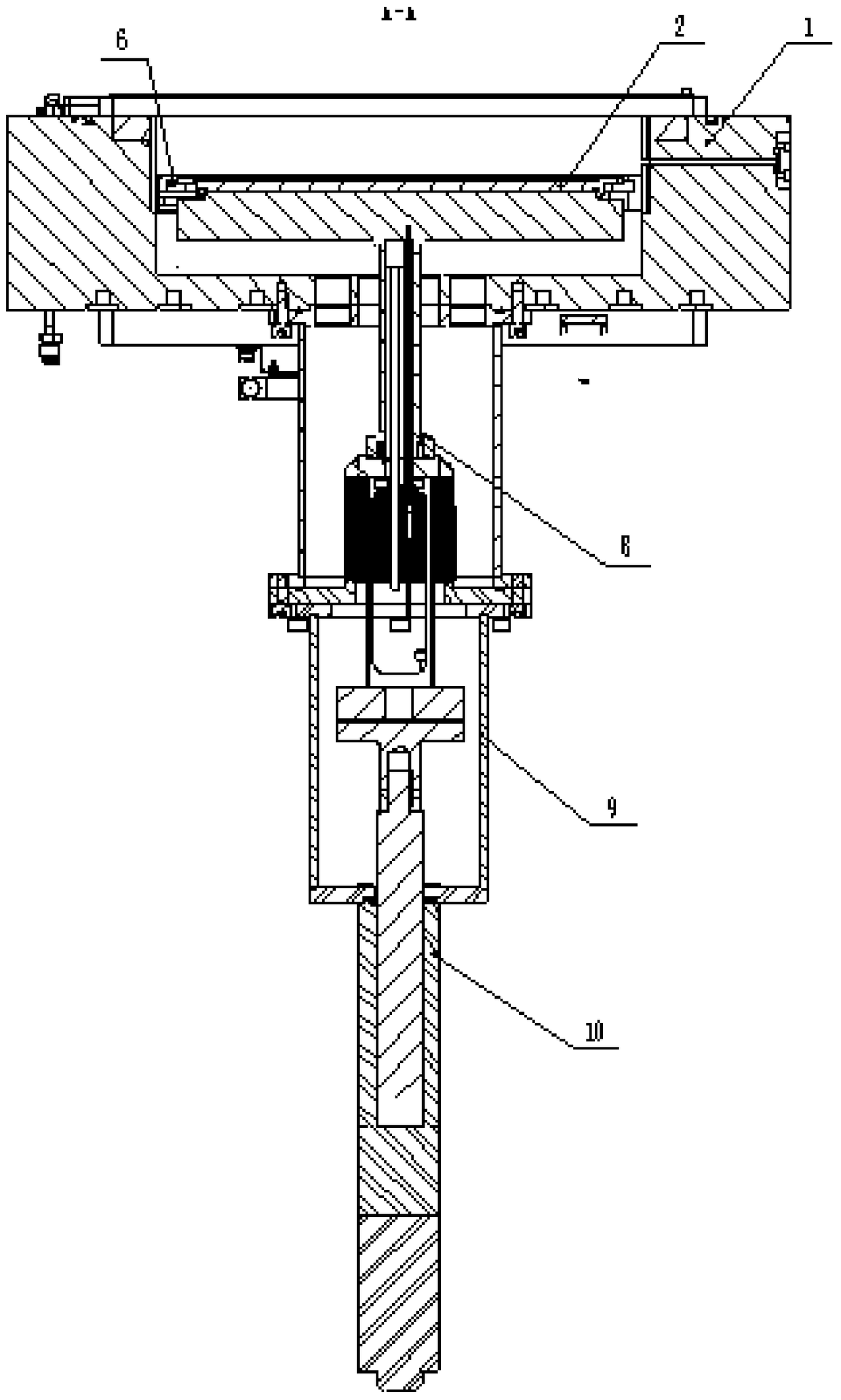

[0022] Such as Figure 1-3 As shown, an automatic film transfer device applied to semiconductor equipment, the automatic film transfer device includes a heating plate assembly 8 , a film transfer chamber 4 and a bracket 9 fixed below the reaction chamber 1 . The bracket 9 is fixed with the lifting motion actuator 10 . The heating plate assembly 8 is arranged on the lifting motion actuator 10 and installed inside the reaction chamber 1 . The heating plate assembly 8 is used to support the tray 2 during the deposition reaction. A linear motion actuator 5 is installed in the film transfer chamber 4, and a transfer paddle 6 is installed on the linear motion actuator 5. The transfer paddle 6 is used to carry the tray 2 for fetching and delivery during the film transfer process. A film transfer chamber door 3 is provided between the reaction chamber 1 and the film transfer chamber 4, and the opening and closing of the film transfer chamber door 3 is controlled by the film transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com