Ultrahigh specific capacity mesoporous Co3O4 nanosheet electrode material and preparation method thereof

An electrode material and nanosheet technology, which is applied in the field of ultrathin mesoporous Co3O4 nanosheet electrode material and its preparation, can solve the problems of poor cycle stability, collapse of electrode material specific capacity, low specific capacity, etc., and achieves high redox activity, Good cycle stability and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An ultrathin mesoporous Co 3 o 4 The preparation method of nano sheet electrode material, comprises the following steps:

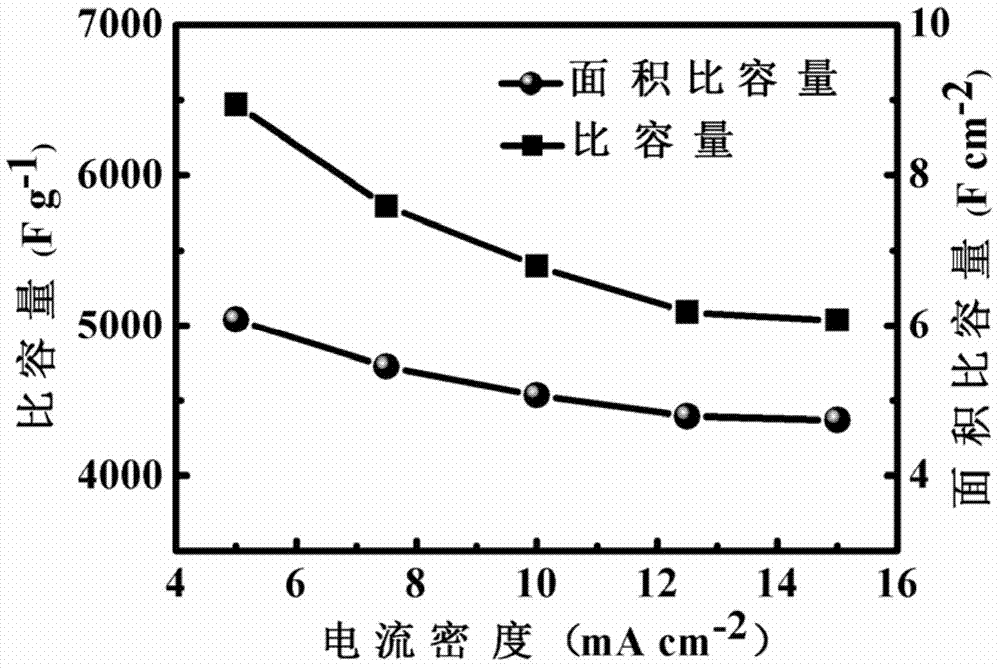

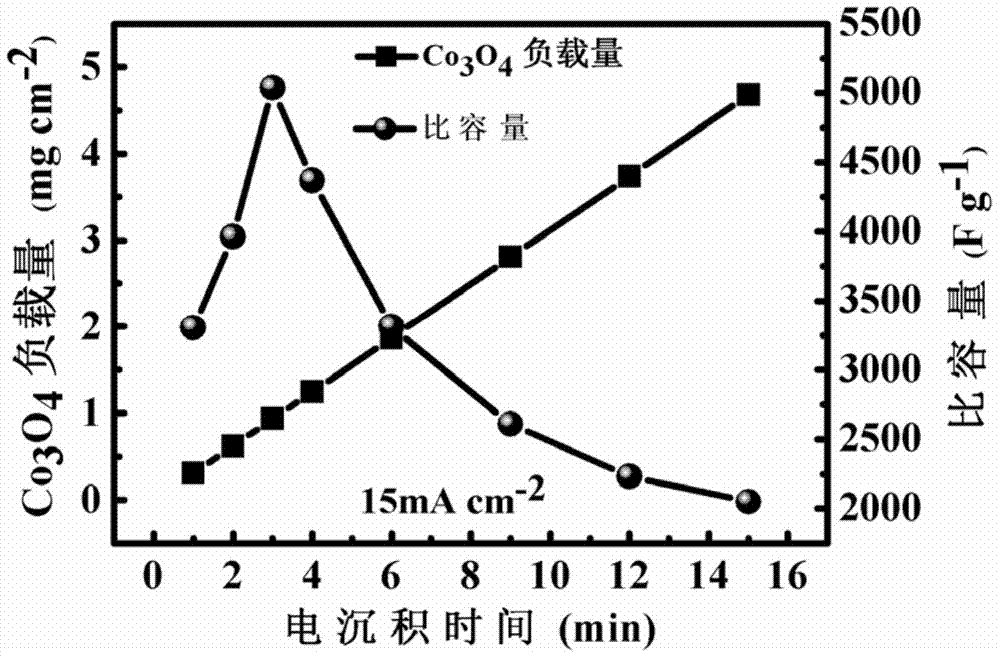

[0028] 1) Preparation of precursor Co(OH) 2 Nanosheet electrode material: a three-electrode system is adopted. The working electrode of the three-electrode system is nickel foam that has been cleaned and vacuum-dried by 3mol / L HCl aqueous solution, acetone, alcohol, and deionization. The counter electrode is a platinum sheet. The electrode is 232 calomel electrode, with 0.1mol / L Co(NO 3 ) 2 and 0.1mol / L KCl mixed aqueous solution as electrolyte solution, at room temperature, 10mA cm -2 Deposit Co(OH) on nickel foam with constant current for 3min 2 Nanosheets;

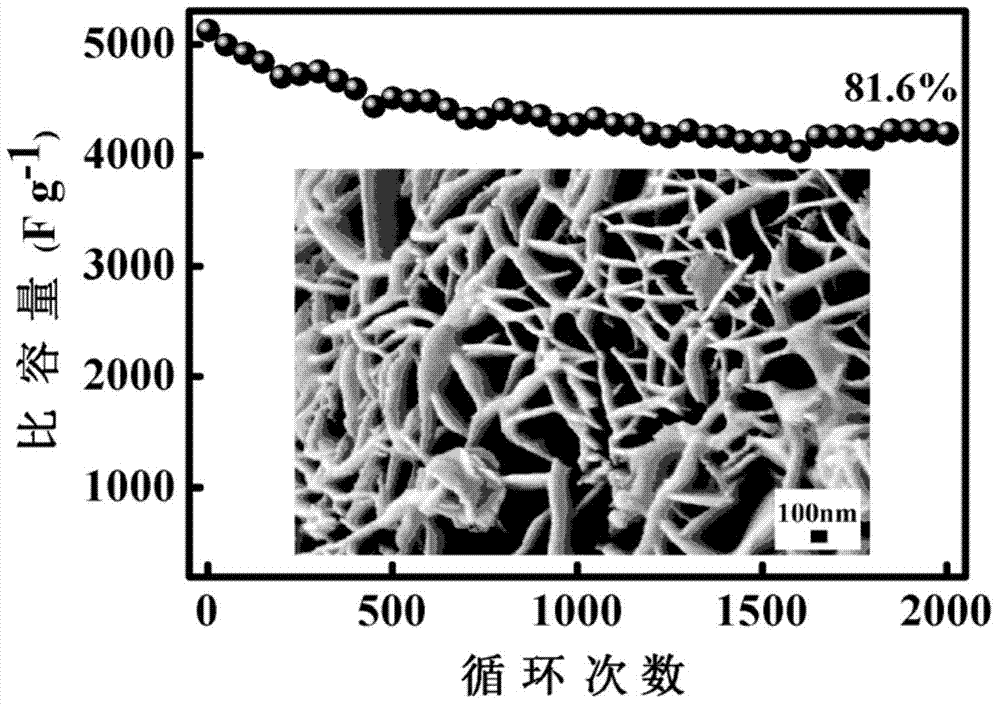

[0029] 2) Preparation of Co 3 o 4 Nanosheet electrode material: The green nickel foam obtained after step 1) constant-current deposition is ultrasonically cleaned with deionized water and alcohol, and dried in the air; the sample is annealed at a high temperature in a horse-boiler fur...

Embodiment 2

[0031] In this embodiment, except that the constant flow deposition time in step 1) is 1 min, other conditions are the same as in embodiment 1.

Embodiment 3

[0033] In this embodiment, except that the constant flow deposition time in step 1) is 2 min, other conditions are the same as in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com