Ship T-shaped bar through hole linear structure

A linear structure and hole line type technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of insufficient smoothness of the opening edge, unsatisfactory fatigue strength, and large stress at the edge of the opening, etc. problem, to achieve the effect of smooth and beautiful line shape, long theoretical life and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

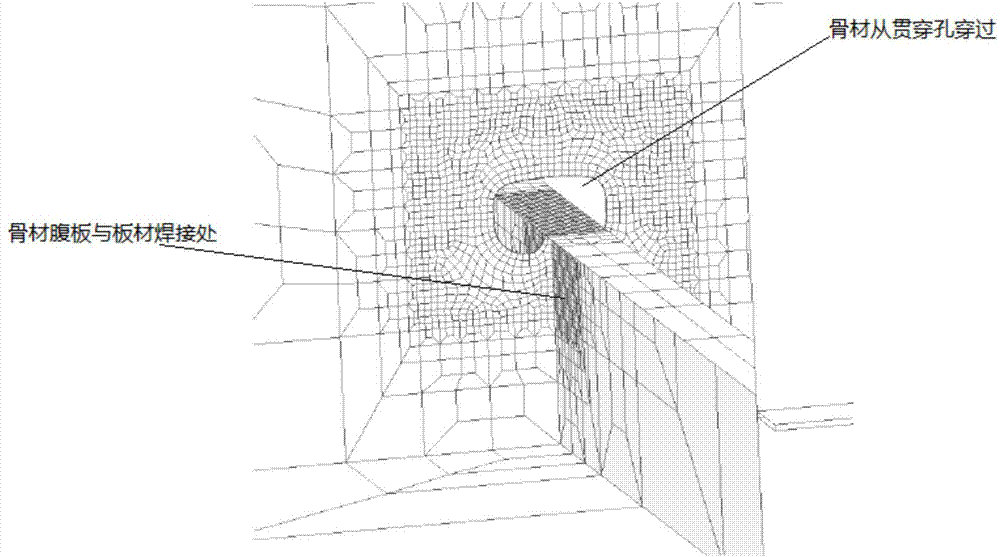

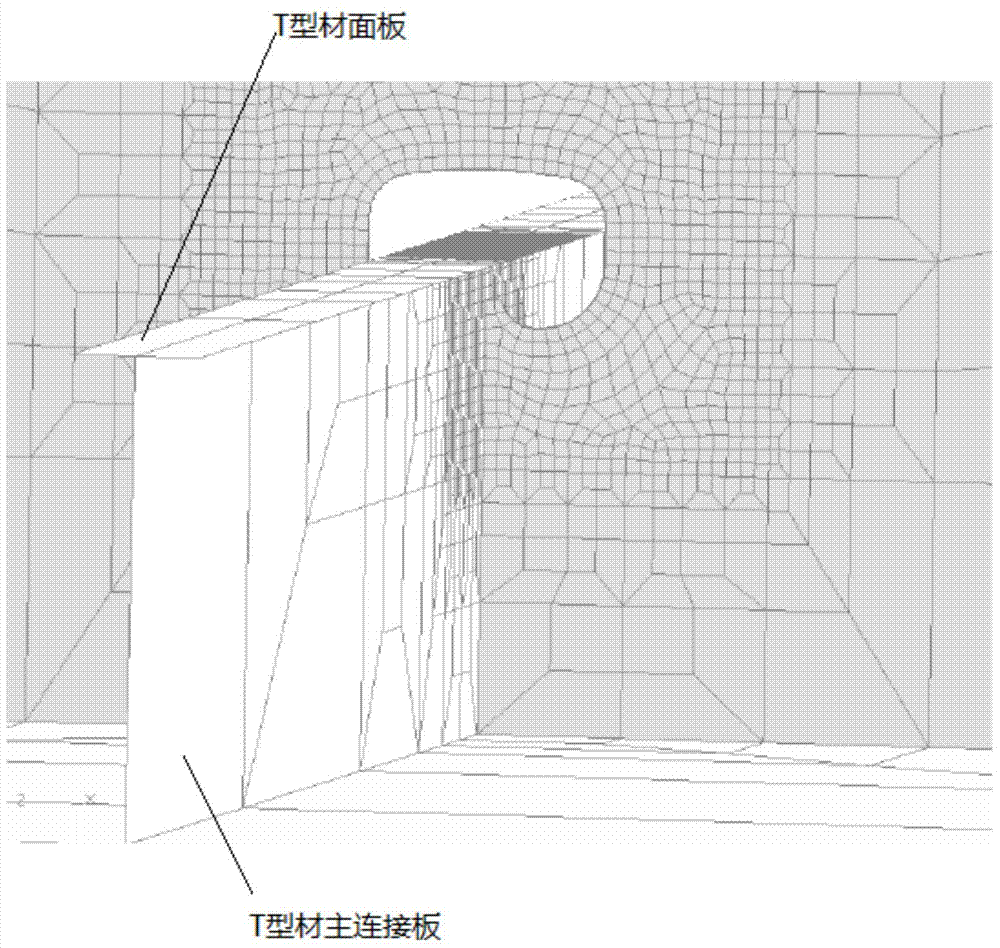

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

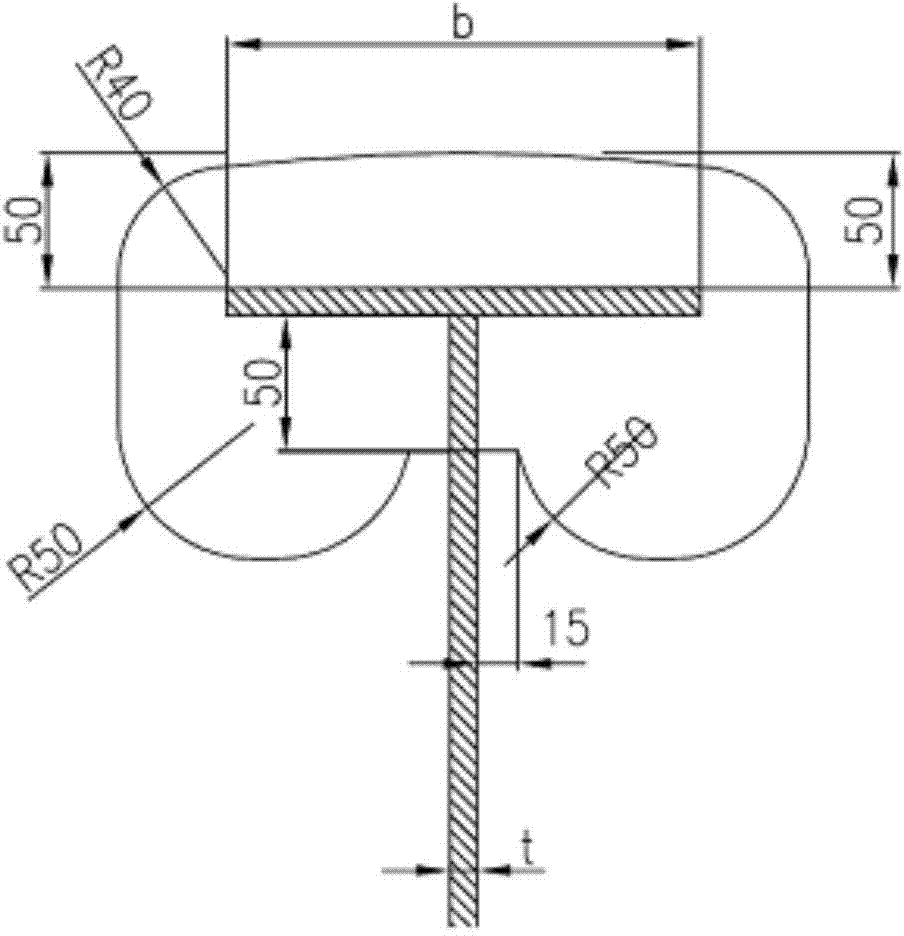

[0026] see Figure 7-8 , a ship T-shaped through-hole linear structure, the T-shaped through-hole has a left-right symmetrical linear structure, and the single-sided linear structure is an elliptical arc, a first circular arc, and a second circle that are smoothly connected in sequence from bottom to top. The form of arc and straight line; the long radius b of the elliptical arc is close to the inside of the T-shaped through hole, and the short radius c is close to the outside of the T-shaped through-hole; the T-shaped through-hole is in the shape of an apple with the head facing down.

[0027] This kind of opening is relatively full and round as a whole. At least one side of the through hole and the T profile is connected by welding. The stress on the free side of the through hole is partly from the profile transmitted through the weld, and pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com