A grinding wheel type regulating valve

A regulating valve and grinding wheel technology, applied in the field of regulating valves, can solve the problems of affecting the working environment, high noise, single structure of internal parts, etc., and achieve the effect of small size and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

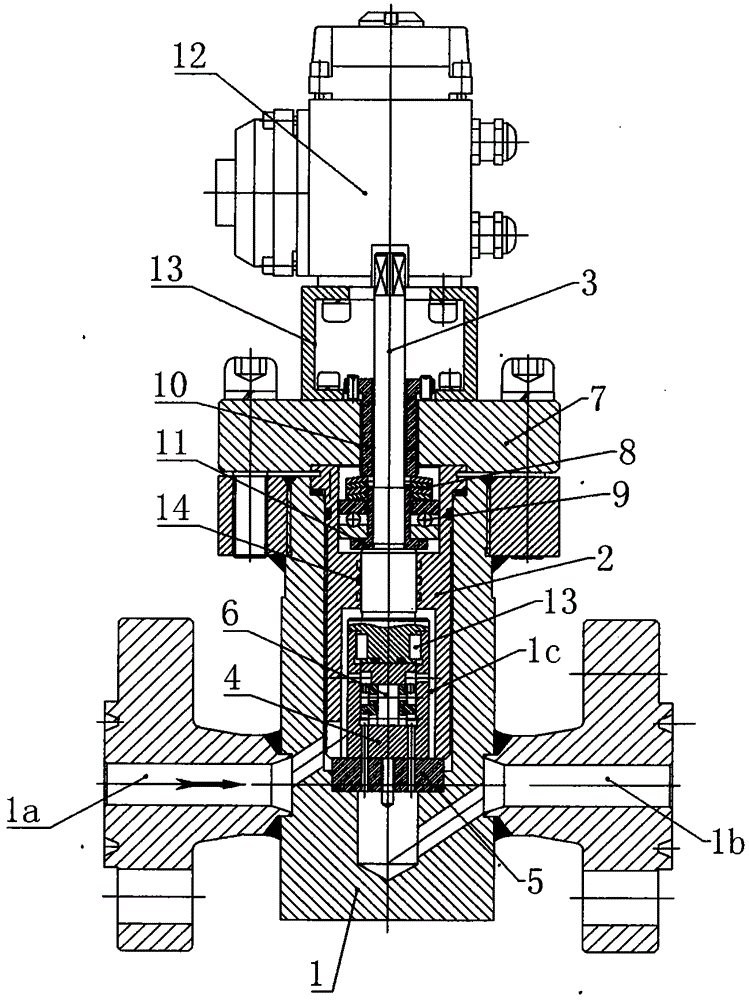

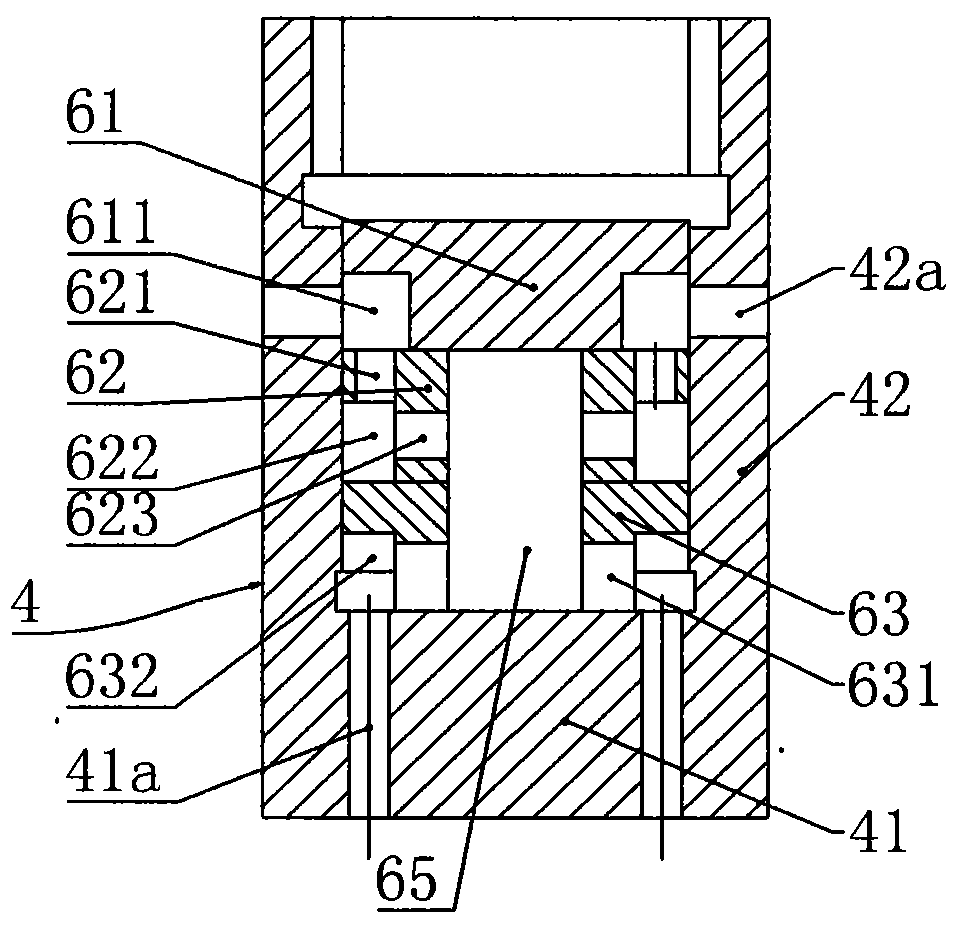

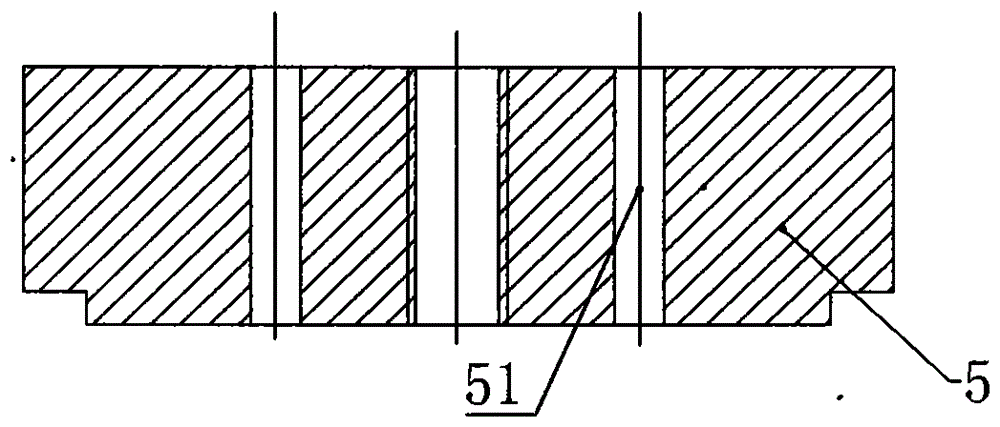

[0025] Combine Figure 1 to Figure 6 As shown, this embodiment discloses a grinding wheel type regulating valve, including a valve body 1, a valve cover 2, and a valve stem 3. The valve body 1 is provided with a valve cylinder 1c, and both sides of the valve body 1 are respectively connected to the valve cylinder The liquid inlet 1a and the liquid outlet 1b of 1c, the valve stem 3 seals through the valve cover 2 and is vertically inserted in the valve cylinder 1c. The valve stem 3 and the valve cover 2 are fitted with multiple O-rings, The valve cylinder 1c is provided with a grinding wheel adjustment assembly. The grinding wheel adjustment assembly includes a movable grinding cylinder 4 fixedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com