Sliding block and sliding device

A technology of sliders and mounting grooves, which is applied to shafts and bearings, linear motion bearings, bearings, etc., and can solve problems affecting the performance of parts and sliding force changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

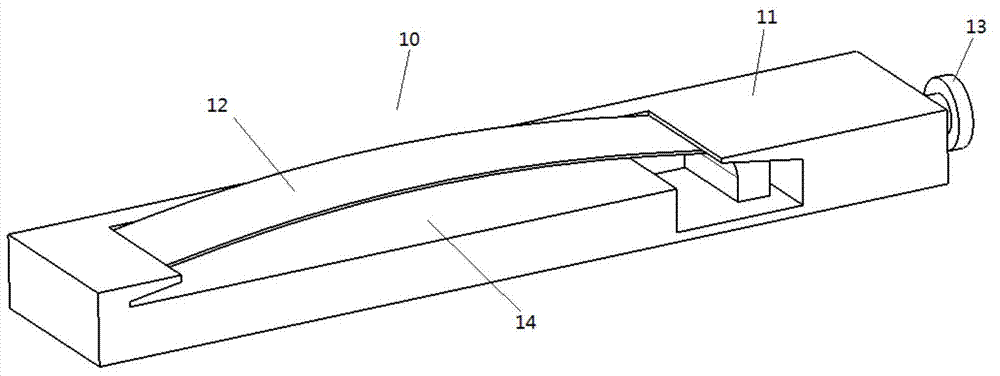

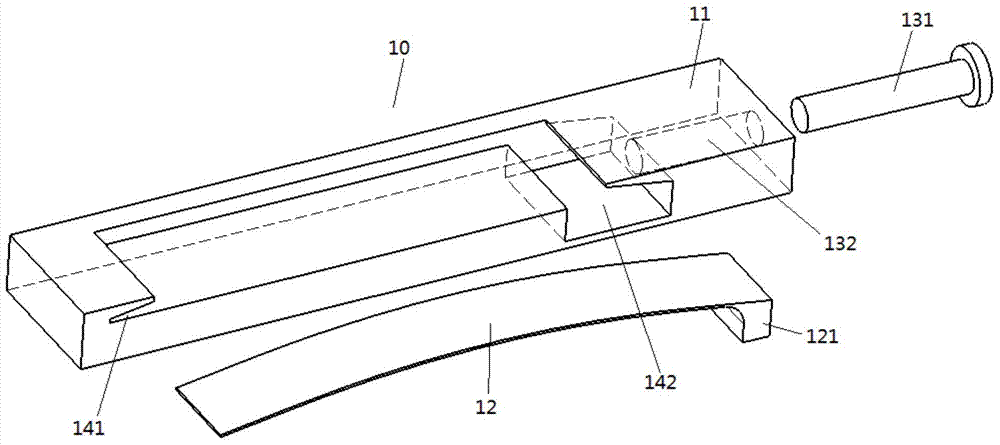

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0020] In the present invention, unless stated to the contrary, the orientation words used such as "up, down, left, right" usually refer to the direction in the drawing, and do not indicate the direction of the product in the actual application state. direction. "Inside and outside" are relative to the product itself and are relative concepts.

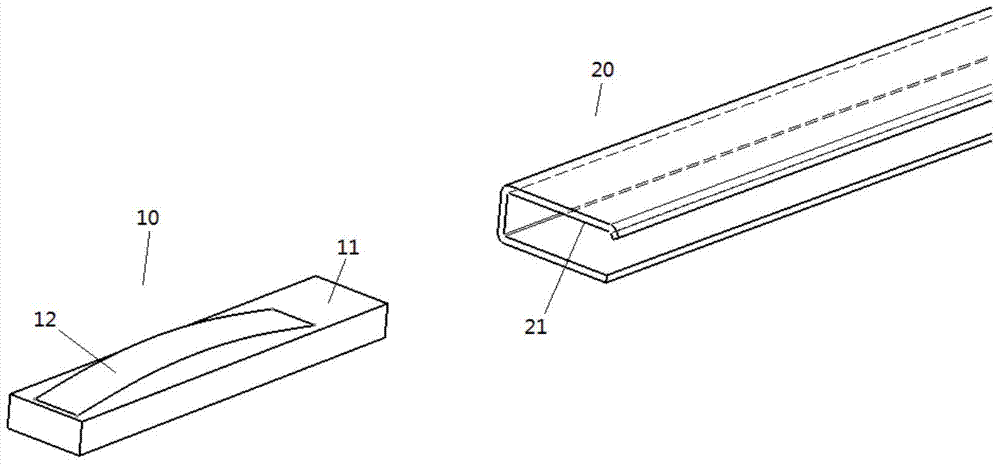

[0021] see first figure 1 , usually, the slider 10 is constrained in the guide rail 20 and relatively slides along the guide rail 20, and the two jointly constitute a sliding device. The slider 10 has a slider matching surface 11 , and the guide rail 20 has a corresponding guide rail matching surface 21 . The frictio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com