Improved cloth dyeing machine structure

A cloth dyeing machine and pipeline technology, which is applied in the direction of liquid/gas/steam jetting to propel fabrics, etc., can solve the problems of increased power consumption and fan power output, and achieve weight reduction, power output, power consumption, and thrust Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is a non-limiting description of the device described in the application of the present invention through the accompanying drawings and examples, in order to make the public better understand the technical solution.

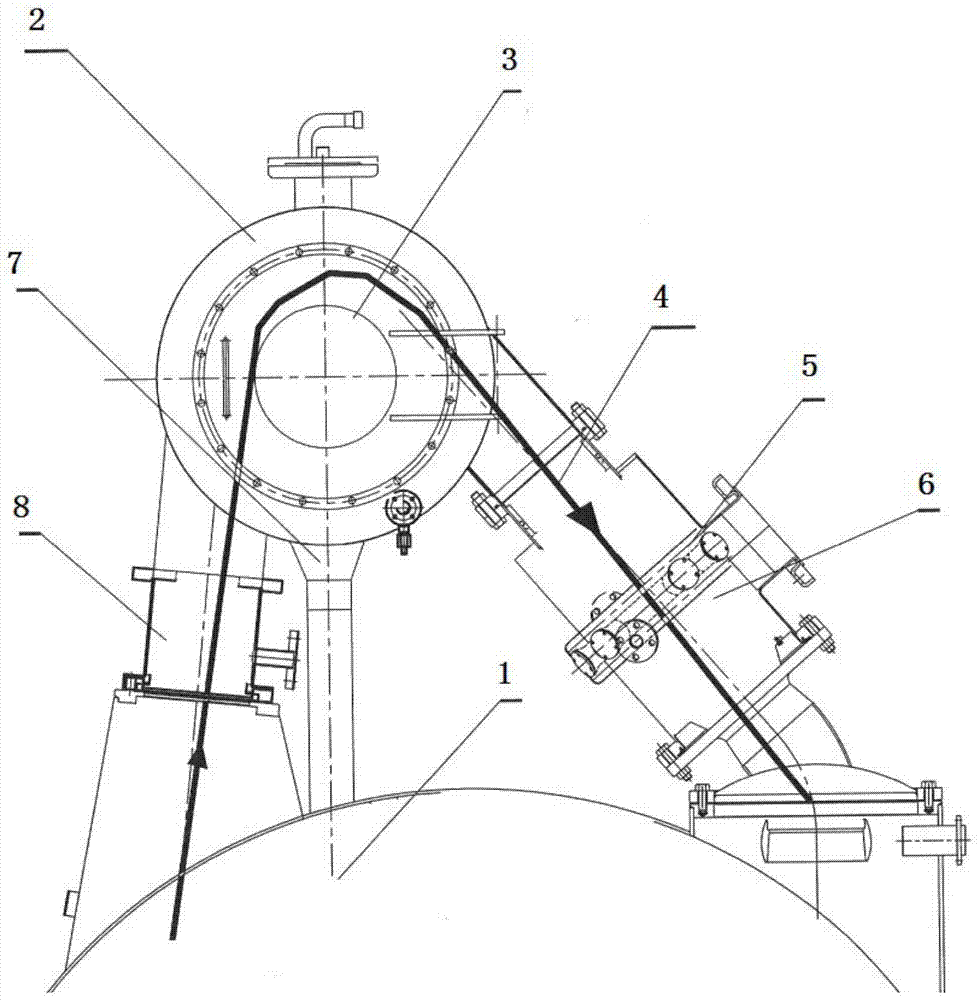

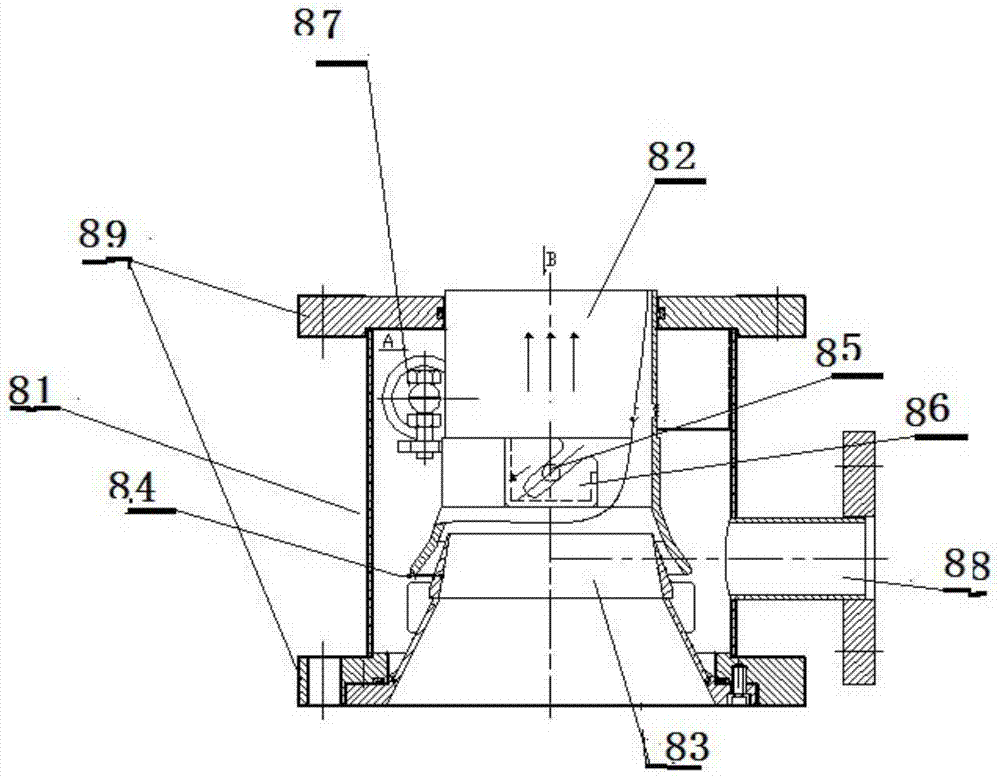

[0026] figure 1 It is a schematic diagram of the top structure of the dyeing machine in the prior art, including a main cylinder 1, and the top of the main cylinder 1 is provided with a front pipeline (left side in the figure), a cylinder head 2 and a rear pipeline (right side in the figure), which are connected in sequence, and the cylinder head 2 is provided with a drum 3, and the fabric 4 is driven by the drum to pass through the front pipeline, the cylinder head 2 and the rear pipeline in sequence, and the rear pipeline is provided with an atomized water nozzle 5 and a main wind nozzle 6 in sequence; figure 2 , the structure of the improved cloth dyeing machine described in the application of the present invention includes the main cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com