A pickle machine for pickling carrots

A carrot and vegetable machine technology, applied in the field of pickle machines, can solve the problems of high labor intensity, deterioration, rot, etc., achieve the effects of good anti-corrosion performance, reduce the difficulty of operation, and avoid the rot of pickles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

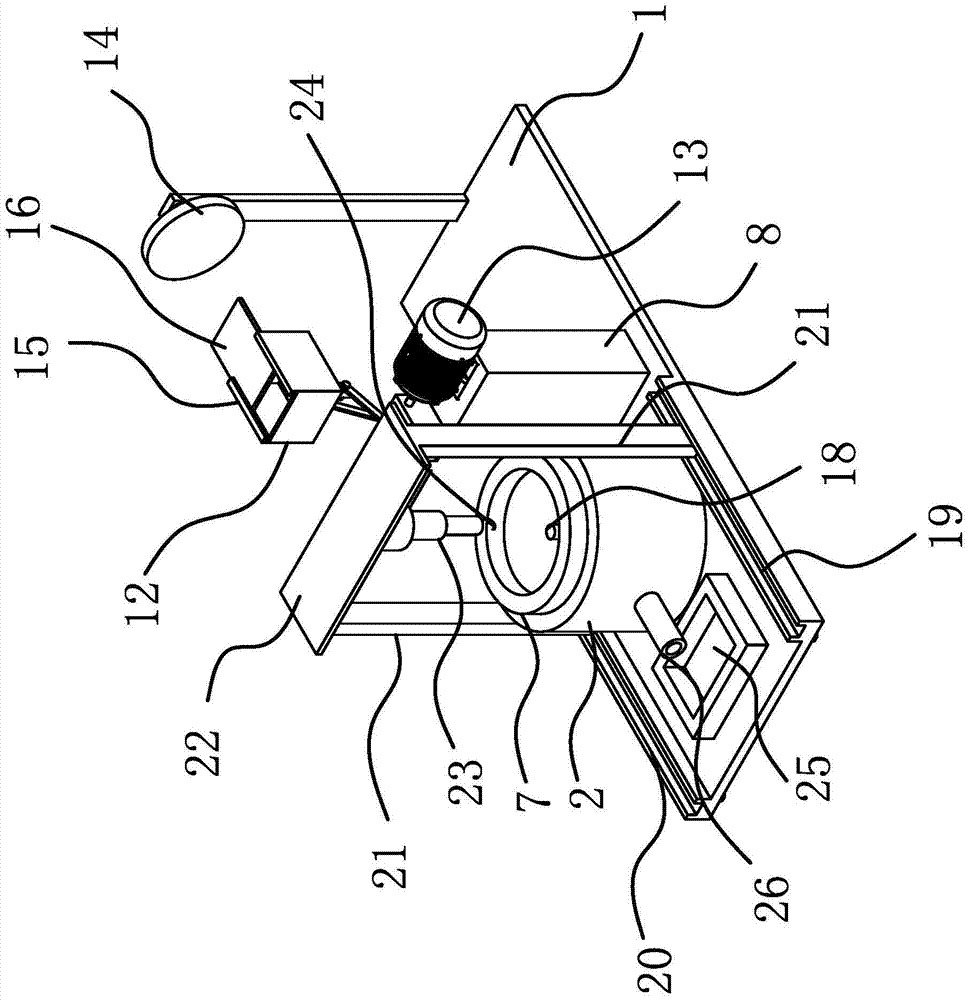

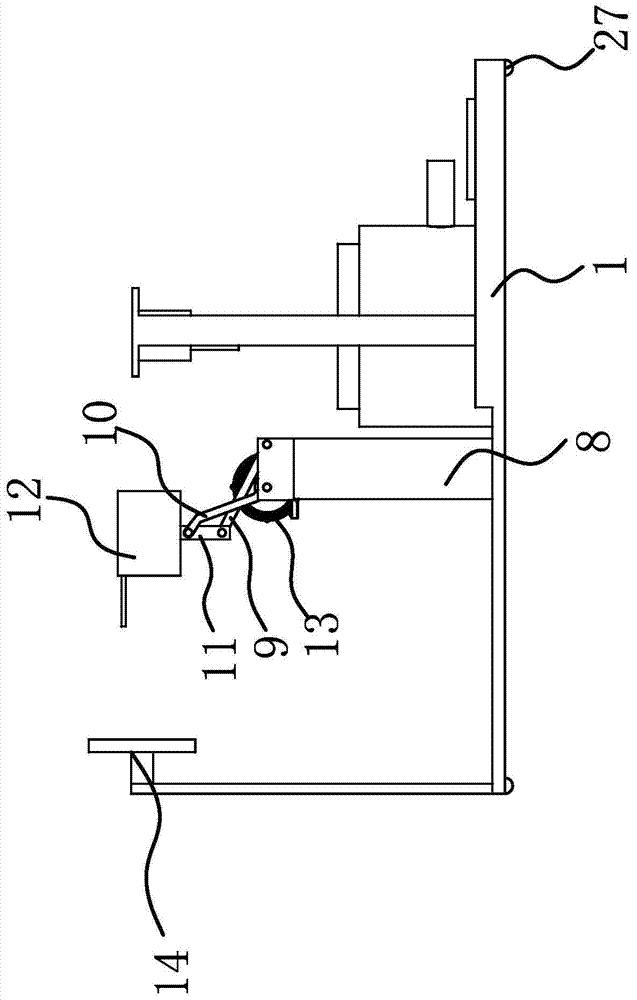

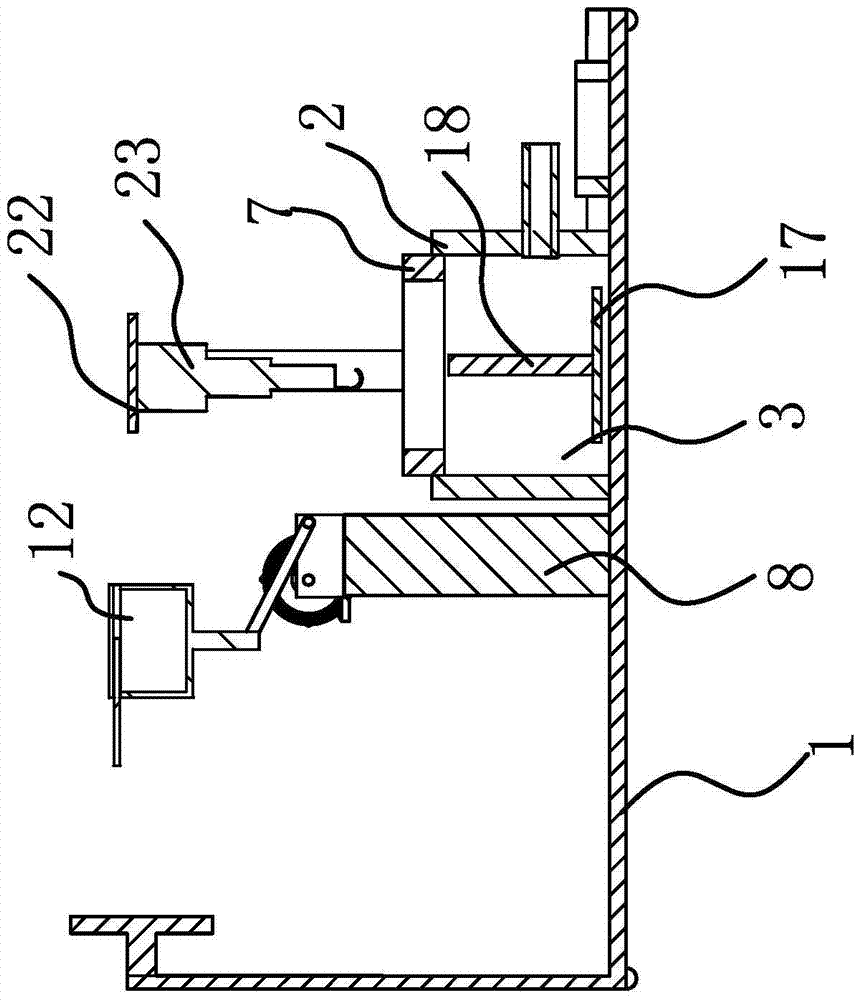

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0029] Such as figure 1 , Figure 4 As shown, the pickle machine includes a base plate 1 and a pickle tank 2, the base plate 1 is arranged along the horizontal direction, the lower end of the pickle tank 2 is fixed on the base plate 1, and a storage chamber for placing pickles is provided in the pickle tank 2 3. The cross-section of the storage chamber 3 is circular, and the upper end surface of the pickle jar 2 is provided with a feed port communicating with the storage chamber 3, and the upper end of the pickle jar 2 can also be detachably connected with a seal for sealing the feed port. Cover plate 4, the center of the lower plate surface of cover plate 4 is fixedly connected with the upper end of a stage clip 5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com