Enameled flat wire production method

A technology of enamelled flat wire and production method, applied to electrical components, circuits, conductor/cable insulation, etc., can solve the problems of inconvenient production, non-universal use, complicated process, etc., and achieve easy maintenance, reduced maintenance cost, and reduced operation effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A method for producing enamelled flat wire, adopting a vertical modular production line to produce enamelled flat wire, specifically as follows:

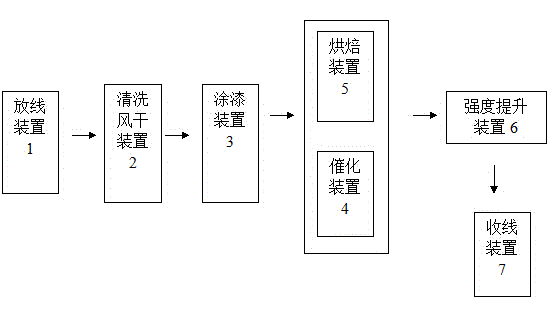

[0017] 1) Set up a vertical modular production line on the enamelled flat wire production line, the vertical modular production line includes a wire-feeding device 1, a cleaning and air-drying device 2, a painting device 3, a catalytic device 4, a baking device 5, and a strength raising device 6 And the take-up device 7, the pay-off device is connected with the painting device through the cleaning and air-drying device, and a catalytic device and a baking device independent of each other are arranged on the rear side of the painting device, and the rear side of the catalytic device and the baking device is connected with the wire-receiving device through a strength raising device. device connection. The catalytic device and the baking device are arranged above the factory building to facilitate the treatment of exhaust gas an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com