Coiled steel strip weight measuring and calculating method

A steel strip and coil technology, applied in the field of keel production, can solve the problems of inconvenient load-bearing steel strip coils, waste, large data deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

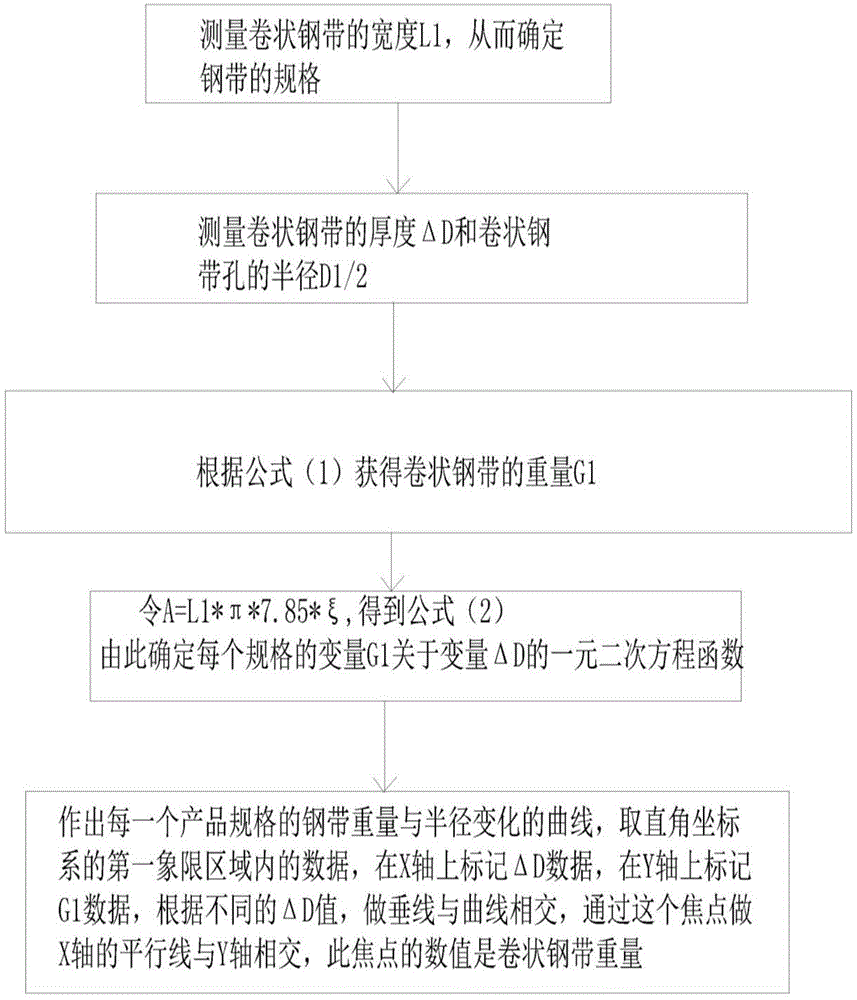

Method used

Image

Examples

Embodiment Construction

[0015] The raw material used in the keel machine is coiled steel strip, which is generally installed on the uncoiler by a forklift. In the production process of the light steel keel, the steel strip is uncoiled by the uncoiler, and then enters the roll of the forming machine for cold bending to form a keel, and the keel enters the cutting machine After the keel is cut, it falls to the slope of the keel tail bracket, and under the action of gravity, it slides onto the belt conveyor, and then the keel slides from the belt conveyor to the receiving frame. After packaging, the production process of the keel is completed. . When the shift is about to be changed or when the inventory is taken at the end of this month, the steel strip may not be used up. For statistical needs, it is necessary to estimate the weight of the steel strip on the uncoiler.

[0016] The technical solutions of the present invention will be described in further detail below with reference to the accompanying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com