Rapid manufacturing method of auvc cooling tower

A manufacturing method and technology of cooling towers, which are applied in the direction of water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve the problems that cooling towers cannot be mass-produced, and facilitate mass-scale production, Simplify the processing process and improve product stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

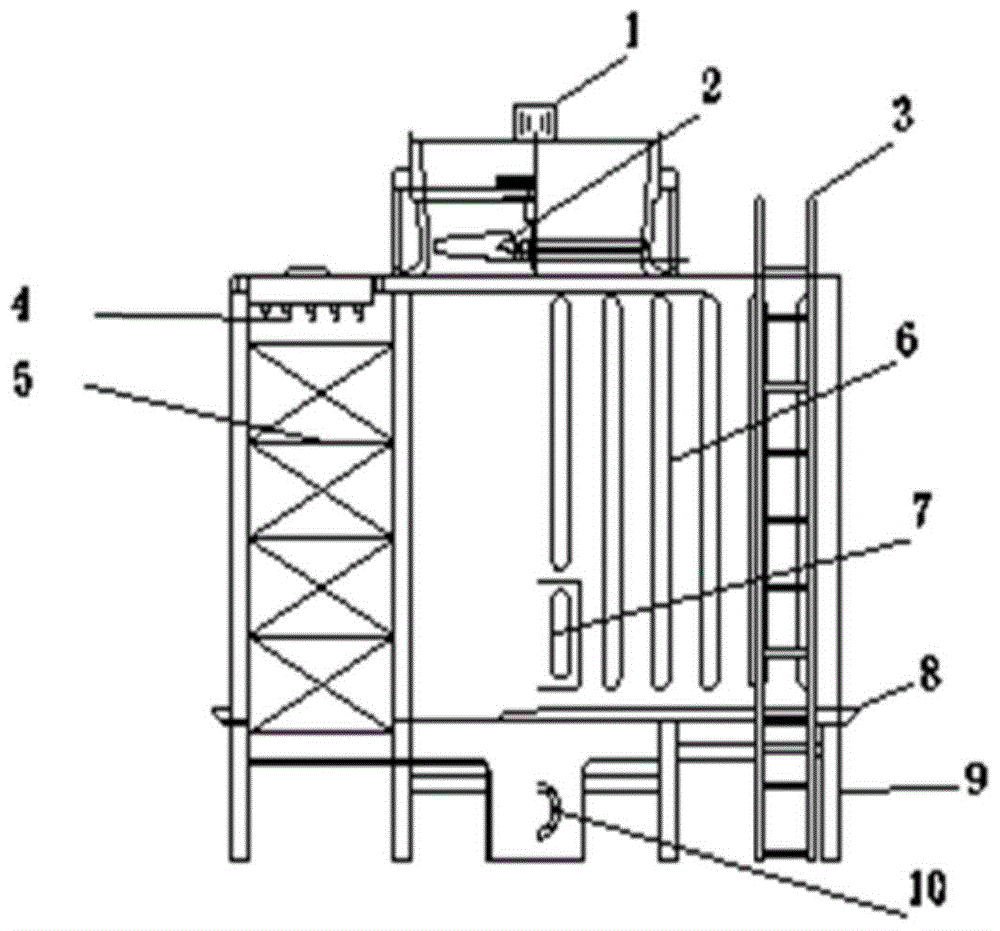

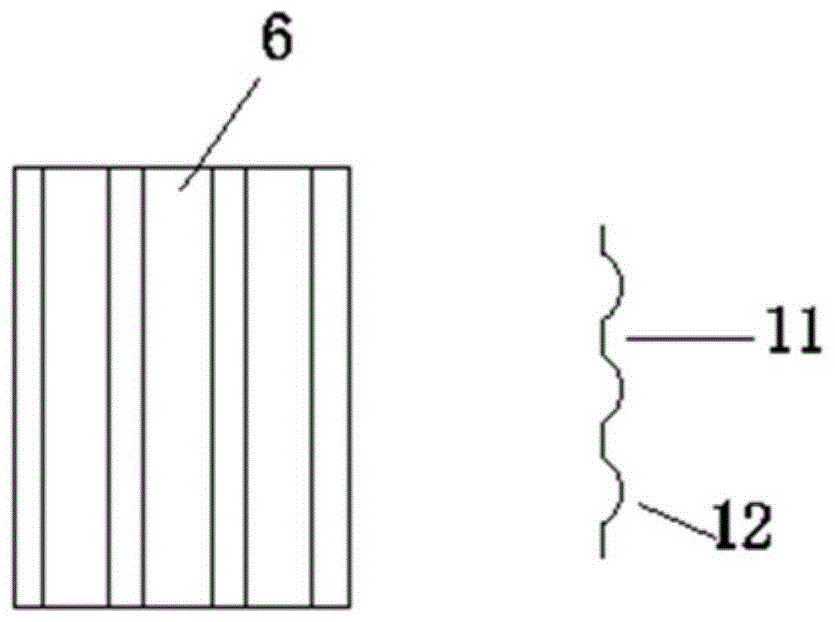

[0026] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

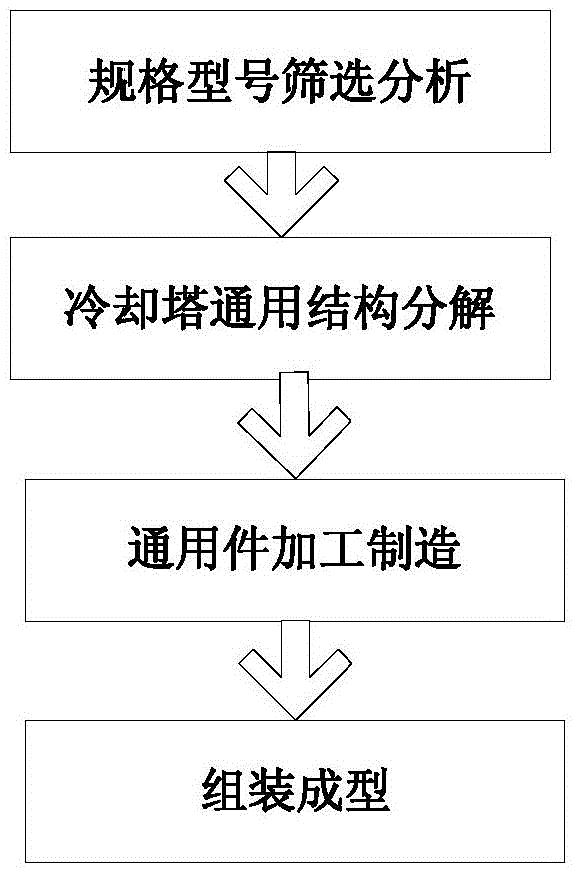

[0027] Such as figure 1 Shown, the present invention discloses a kind of AUVC cooling tower rapid manufacturing method, comprises the following steps:

[0028] The first step is the screening and analysis of specifications and models. Statistical analysis of the models of existing cooling towers is carried out, and the cooling towers with the highest frequency of use are used as cooling towers with general processing structures for the rapid manufacturing method of cooling towers. Since more than 90% of the cooling towers currently used are flow-type FRP cooling towers, the cooling towers with general processing structures are cross-flow FRP cooling towers.

[0029] The second step is to decompose the general struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com