Valve rocker mounting mechanism and gasoline engine thereof

A technology of valve rocker arm and installation mechanism, applied in the direction of machine/engine, valve device, mechanical equipment, etc., can solve the problems of wasting fuel, inaccurate movement, and lax closing, etc., so as to reduce the working load of the timing shaft and ensure smooth operation. The effect of stability and accuracy, simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

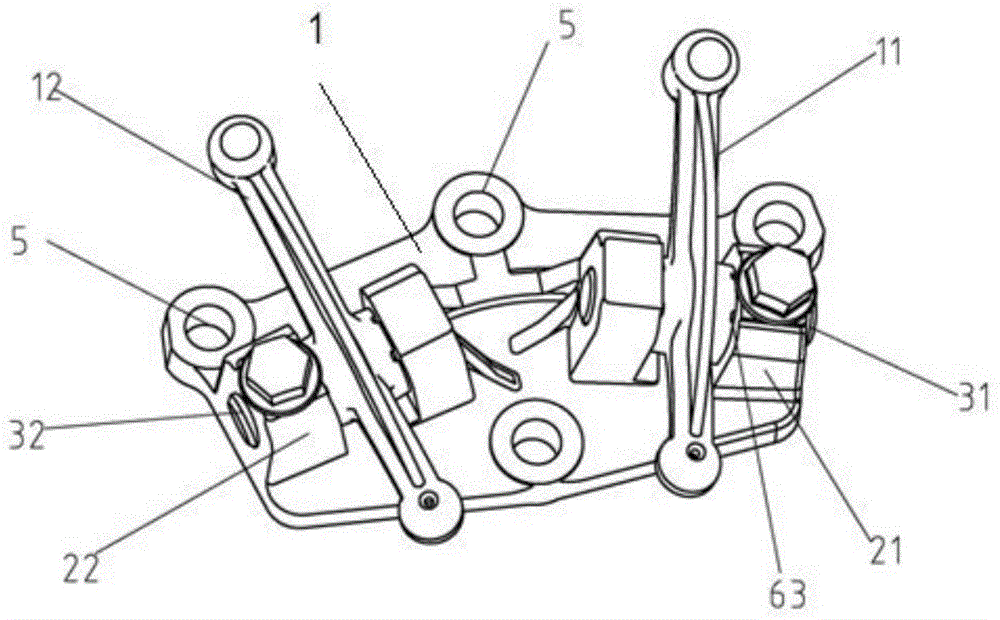

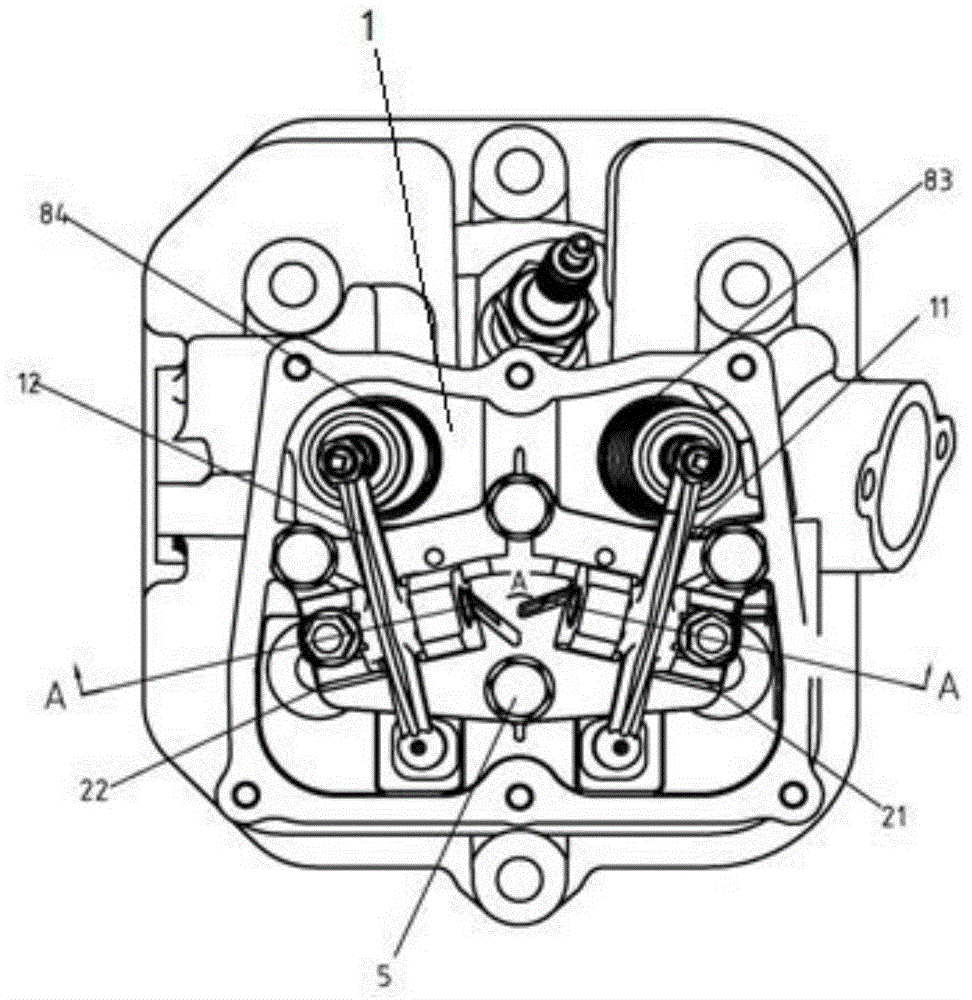

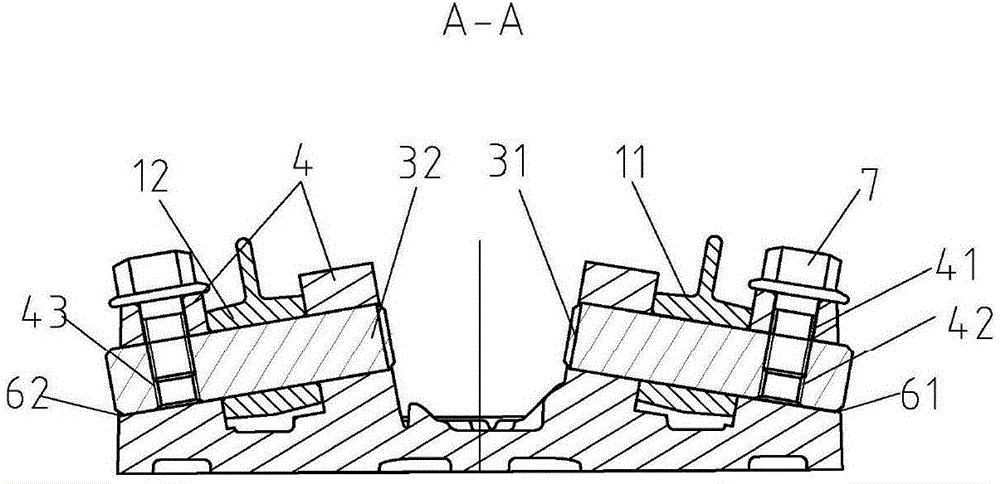

[0024] see Figure 1-5 , is a structural schematic diagram of an embodiment of the present invention, providing a valve rocker arm installation mechanism, which includes a valve rocker arm installation seat 1, and a valve rocker arm installation seat 1 is provided with a rocker arm 11 for installing an intake valve and an exhaust valve rocker The intake valve rocker arm seat 21 and the exhaust valve rocker arm seat 22 of the arm 12, the intake valve rocker arm 11 and the exhaust valve rocker arm 12 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com