Formwork jacking tool for constructing post-cast strip of cast-in-place slab and formwork supporting construction method

The technology of post-casting belt and cast-in-place slab is applied in the field of formwork support tools, which can solve the problems of increased construction difficulty of formwork support system, inconvenient chiseling of concrete construction joints, inconvenient cleaning of post-casting belts, etc., so as to eliminate the problems of quality and safety. The effect of avoiding hidden dangers, improving bearing conditions and shortening construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

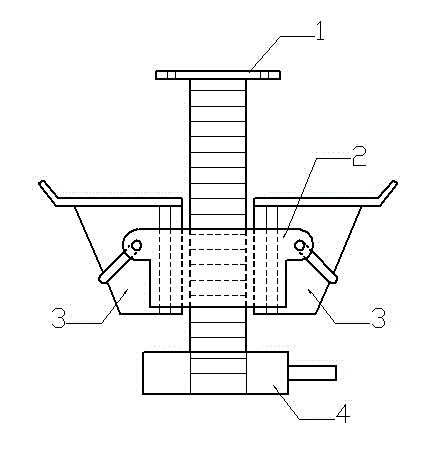

[0032] Such as Figure 1-Figure 8 As shown, a formwork jacking tool used in the construction of cast-in-place slab post-cast belt, which includes a jacking 1, an adjustable support nut 2, at least one bracket 3, and an adjustment nut 4. Wherein, the jacking 1 includes a screw 7, a supporting plate A6 fixed on the top of the screw 7, the supporting plate A6 is provided with nail holes 5, and the supporting plate A is a rectangular plate with a certain thickness, which is welded to the top of the screw 7. together. The adjustable support nut 2 includes a nut body 8 with an internally threaded hole 11, two brackets 21 are arranged symmetrically on the outside of the nut body 8, and there is a chute 12 arranged axially along the nut body 8 in the bracket 21 A U-shaped snap ring 10 connected to the bracket 21 is also provided on the outside of the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com