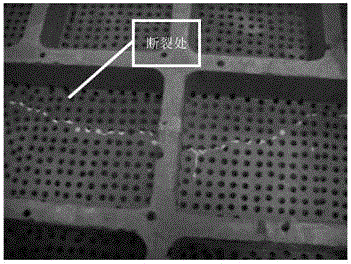

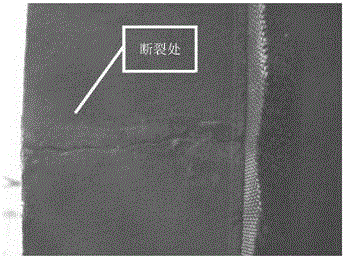

A Repairing Method of Fractured Graphite Mold

A graphite mold and repair method technology, applied in the field of graphite mold repair, can solve the problems of easy expansion of graphite mold, easy delay of production cycle, increase of production cost, etc., and achieve the effects of low cost, reduced production cost and short working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention uses carbon powder, silicon carbide powder, modified acrylic glue, honey and alcohol as raw materials, and carbon powder and silicon carbide powder provide a substrate for subsequent chemical vapor deposition. The modified acrylic glue has a bonding effect, but It is easy to solidify at room temperature, and honey contains volatile oil and glucose, which have the effect of dissolving and solidifying. After mixing these substances, add alcohol as a solvent to configure the adhesive, and coat the mixture evenly on the mold At the fracture, add auxiliary tooling, dry naturally at room temperature, and then carry out chemical vapor deposition. During the high temperature process, honey and acrylic resin are carbonized. The ceramic phase structure sticks the mold together, so as to achieve the purpose of repairing the mold.

[0034] The invention solves the repair of the vulnerable graphite mold with high frequency of use and low strength requirement, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com