Mandrel component

A shaft component and mandrel technology, applied in the field of mandrel components, can solve problems such as difficult hollowing, high-precision positioning, difficult disassembly, inconvenient use, etc., and achieve the effect of precise axial positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The mandrel assembly according to the present invention will be described in detail below with reference to the accompanying drawings.

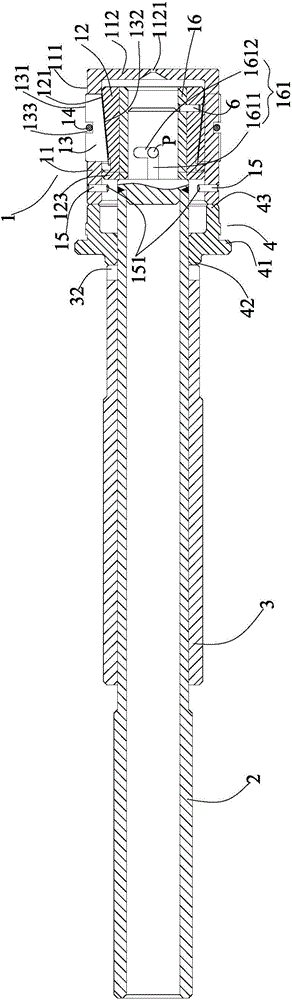

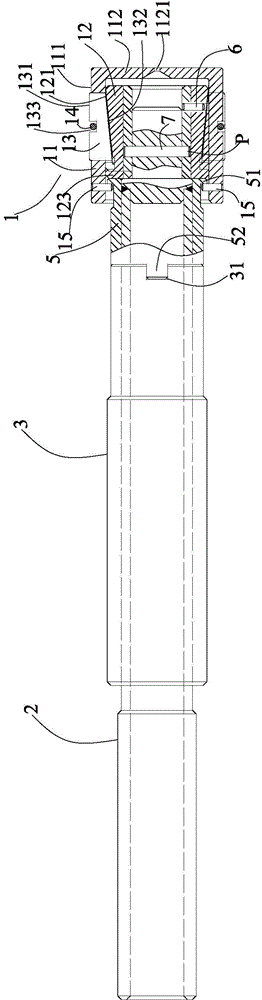

[0050] refer to Figure 1 to Figure 10 , the spindle assembly according to the present invention includes a spindle body 1 , an operating rod 2 , an outer sleeve 3 , a positioning sleeve 4 and a dismounting sleeve 5 .

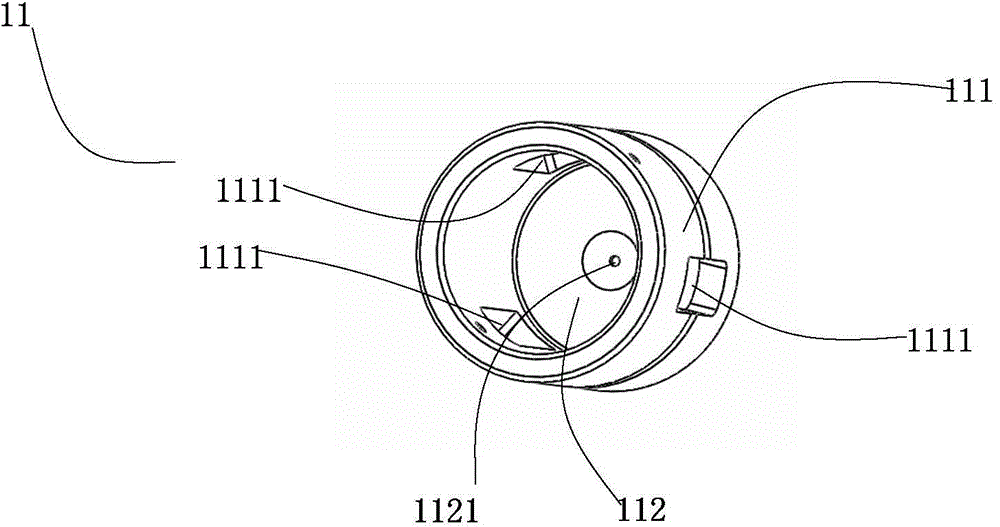

[0051] The mandrel body 1 is used to be placed in the workpiece hole, and includes a mandrel 11 , a movable core sleeve 12 , a plurality of centering expansion blocks 13 , an elastic ring 14 , two stopper pins 15 and a push-pull sleeve 16 . The mandrel 11 is a cylindrical body and a plurality of through grooves 1111 uniformly distributed along the circumferential direction are formed on the peripheral wall 111 . The movable core sleeve 12 is in the form of a cylinder and is sheathed in the mandrel 11 so that it can move axially. It has: an outer wall surface 121; wedge-shaped grooves 122 are arranged on the outer wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com