Hoe production method

A manufacturing method and hoe technology, applied in hoes, manufacturing tools, applications, etc., can solve the problems of high labor intensity, complicated process, and long time required, and achieve the effects of enhanced ductility, high degree of mechanization, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

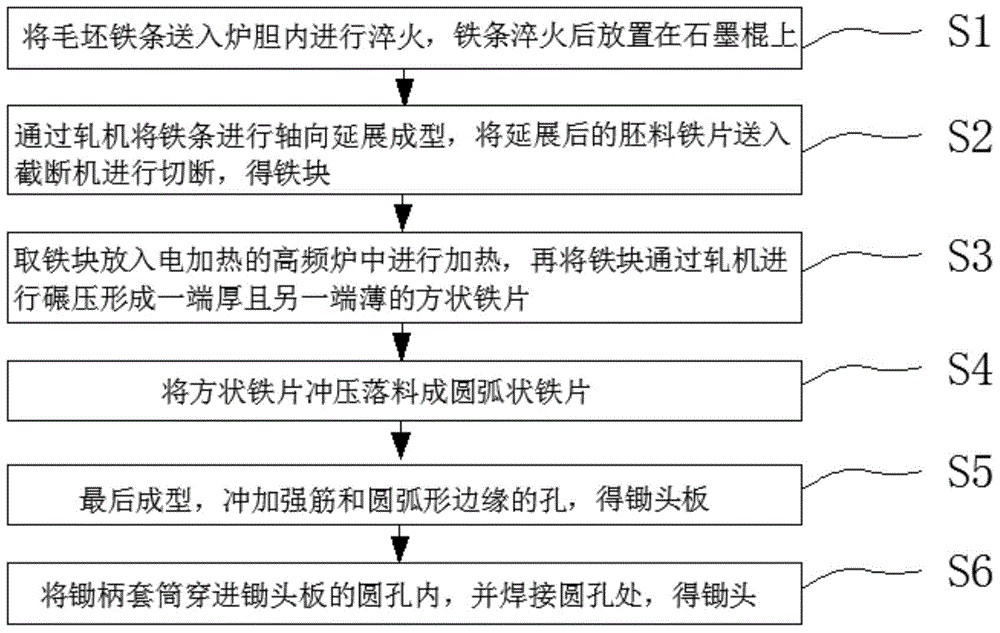

[0022] Such as figure 1 Shown, a kind of manufacture method of hoe comprises the following steps:

[0023] Step S1. Send the rough iron bars used for making hoes into the furnace for quenching, take out the quenched iron bars, and place them on graphite sticks;

[0024] Step S2. The iron bar after natural heat dissipation is axially stretched and formed by a rolling mill, and the stretched billet iron sheet is sent to a cutting machine for cutting to obtain an iron block;

[0025] Step S3. Take the iron block and put it into an electrically heated high-frequency furnace to heat until the iron block is heated to 800-1100 degrees, and then roll the iron block through a rolling mill to form a square iron sheet with on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com