Electric machinery

A technology of machinery and appliances, applied in the field of electromechanical appliances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

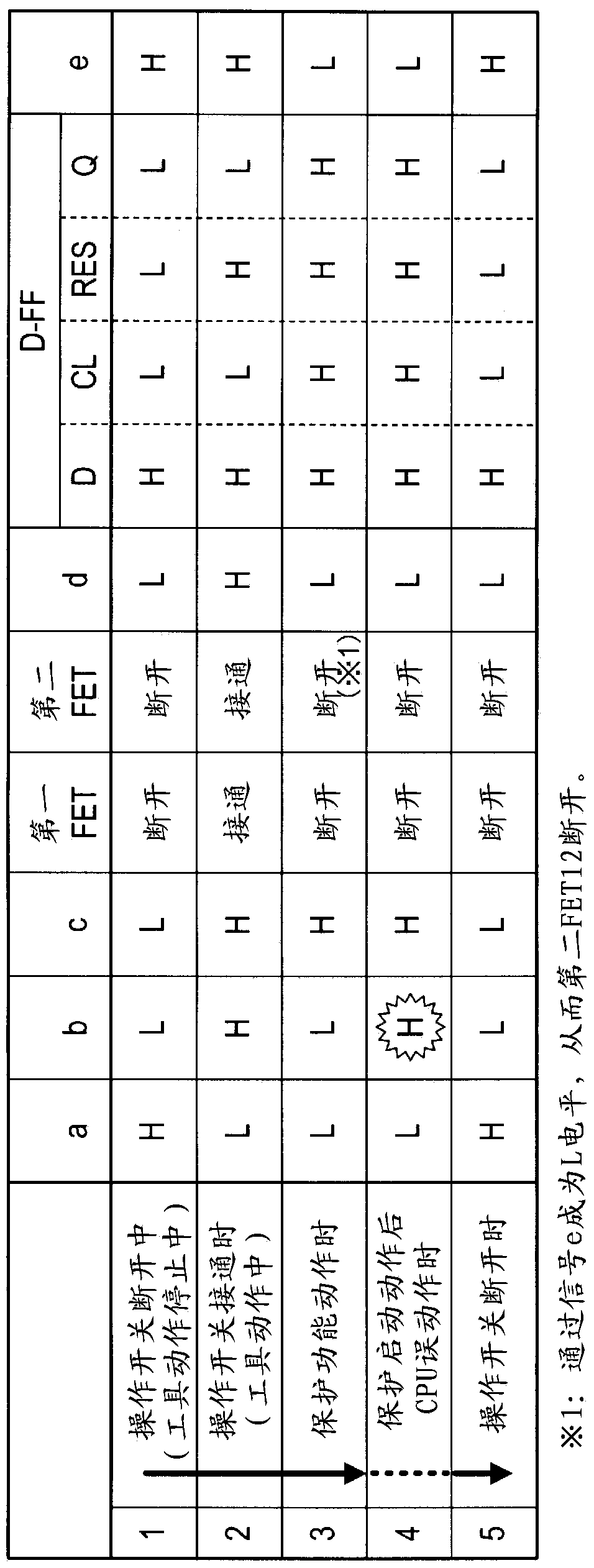

[0037] (1) Electrical structure of electric tool 1

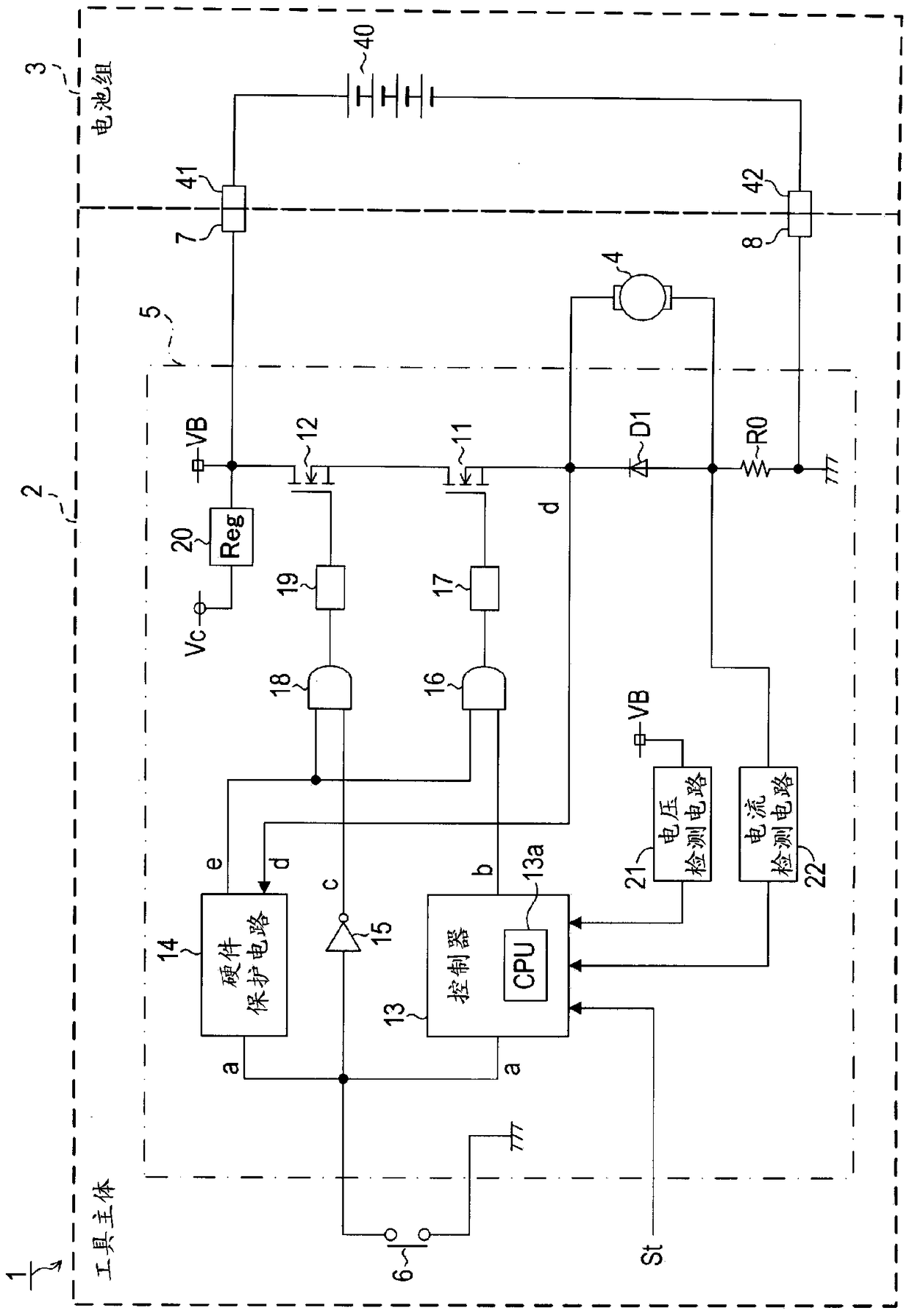

[0038] figure 1 The electric tool 1 according to the present embodiment shown is, for example, an electric tool for drilling a workpiece and performing screw fastening work.

[0039] Such as figure 1 As shown, the electric tool 1 of this embodiment includes a tool body 2 and a battery pack 3 . The battery pack 3 is detachable relative to the tool body 2 . figure 1 A state in which the battery pack 3 is attached to the tool body 2 is shown.

[0040] The battery pack 3 includes a battery 40 , a positive terminal 41 and a negative terminal 42 . The battery 40 has a plurality of battery cells connected in series, or a plurality of battery cells connected in series and parallel. Each battery cell in this embodiment is a secondary battery (for example, a lithium ion secondary battery) cell.

[0041] In the battery pack 3 , the positive electrode of the battery 40 is connected to the positive terminal 41 , and the negative el...

no. 2 approach

[0116] use Figure 4 An electric power tool 51 according to the second embodiment will be described. Figure 4 The power tool 51 of this second embodiment is shown with figure 1 Compared with the electric tool 1 of the first embodiment shown, the structure of the control circuit 53 of the tool body 52 is partially different.

[0117] Specifically, the signal input to the second input terminal 32 of the hardware protection circuit 14 is the motor state signal d output from the controller 13 in the second embodiment, as opposed to the motor state signal d in the first embodiment. drive signal b. Except for the difference in the signal input to the second input terminal 32 of the hardware protection circuit 14, it is the same as the electric power tool 1 of the first embodiment.

[0118] When the motor drive signal b is at H level, it can be determined that the motor 4 is rotating. On the other hand, when the motor drive signal b is at L level, the first drive signal from the...

no. 3 approach

[0124] use Figure 5 The electric power tool 61 of the third embodiment will be described. Figure 5 The electric tool 61 of this third embodiment is shown with figure 1 Compared with the electric tool 1 of the first embodiment shown, the structure of the control circuit 63 of the tool body 62 is partially different.

[0125] Specifically, the signal input to the second input terminal 32 of the hardware protection circuit 14 corresponds to the motor state signal d in the first embodiment, and is output from the first AND circuit 16 in the third embodiment. first drive signal. Except for the difference in the signal input to the second input terminal 32 of the hardware protection circuit 14, it is the same as the electric power tool 1 of the first embodiment.

[0126] When the first drive signal output from the first AND circuit 16 is at H level, it can be determined that the motor 4 is rotating. On the other hand, when the first drive signal is at L level, the first FET 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com