Detection system of metal surface defect and detection method thereof

A metal surface and defect detection technology, applied in measuring devices, instruments, material analysis by electromagnetic means, etc., can solve problems such as inability to distinguish between inner and outer wall defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

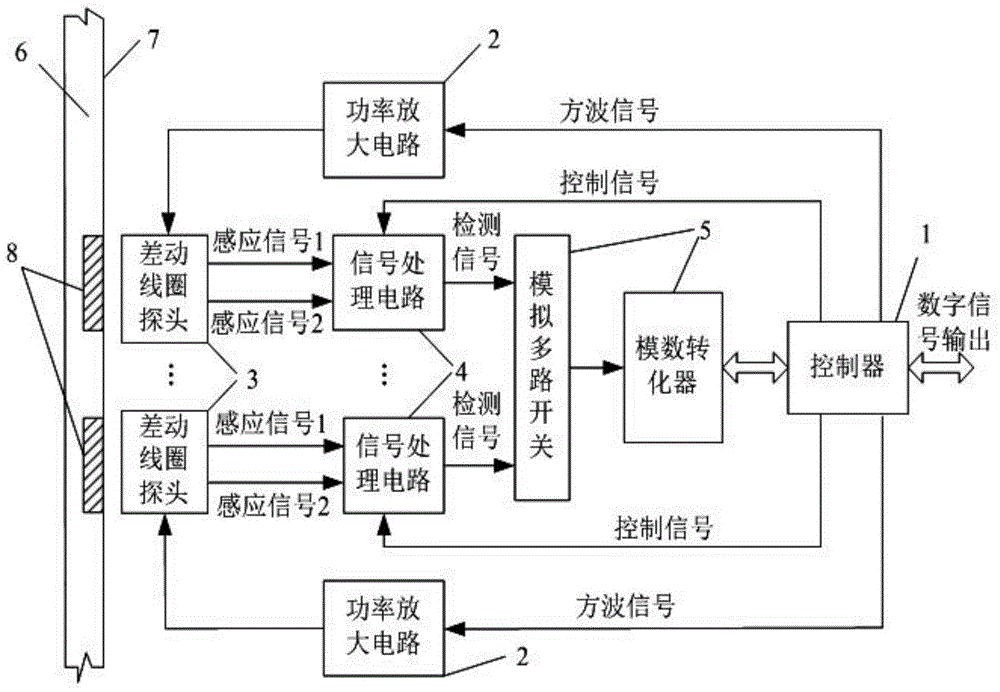

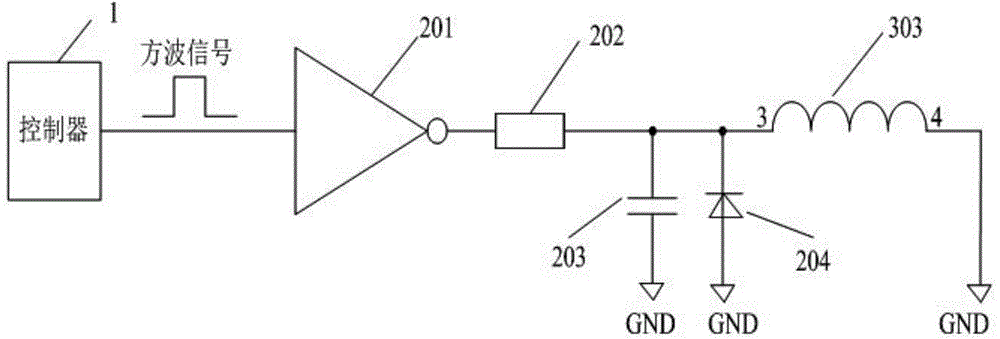

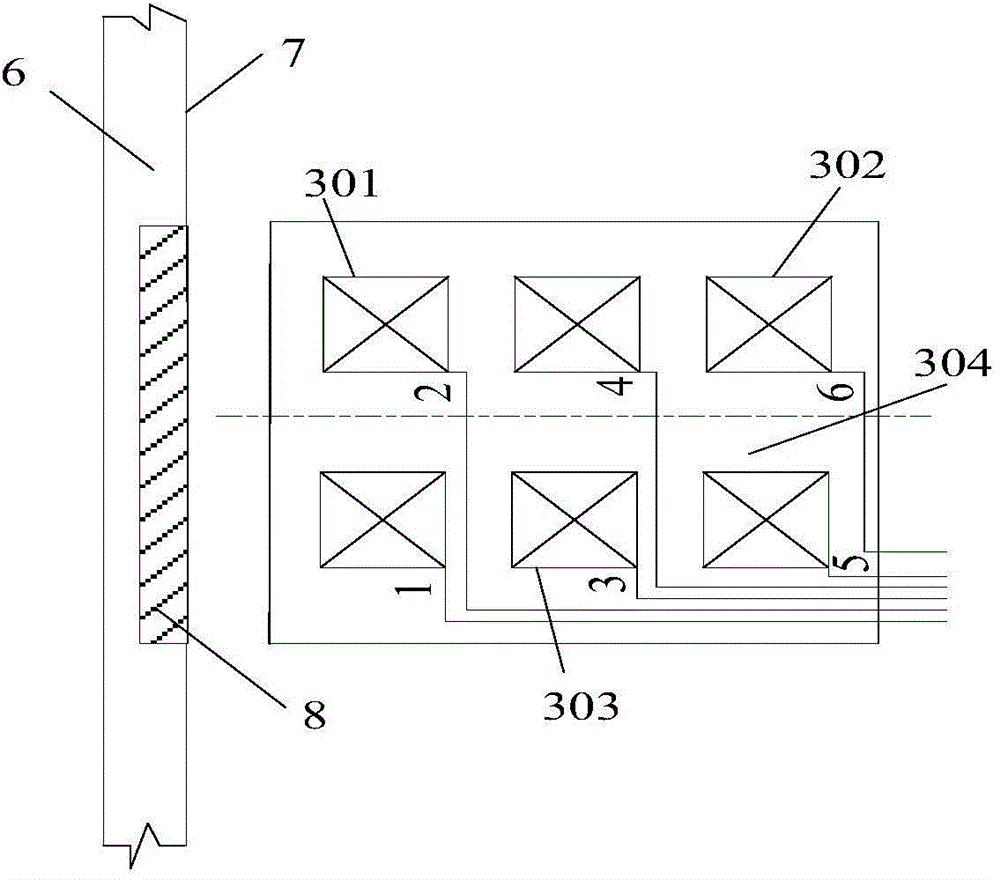

[0021] figure 1 It is a schematic diagram of the detection system of the present invention, which consists of a controller 1, two power amplifier circuits 2, two differential coil probes 3, two signal processing circuits 4, an analog multiplexer and an analog-to-digital converter 5, etc. The modules form a detection system, in which the power amplifier circuit 2, the differential coil probe 3, and the signal processing circuit 4 form an eddy current detection module in one-to-one correspondence, that is, an eddy current detection module equipped with 2 channels; the controller 1, the analog multiplex switch and the analog-to-digital conversion The device constitutes a data acquisition module. The eddy current detection module outputs a DC voltage signal that corresponds intuitively to the surface defects of the detected metal and can be captured at a lower sampling speed, and the data acquisition module performs A / D conversion, acquisition and output of the signal. 1 controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com