Bidirectional sectional feeding automatic fiber extractor

A hemp machine and automatic technology, which is applied in the field of two-way segment feeding automatic hemp scraper, can solve the problems of small soft strength, easy to be interrupted and fly out, and the combined force of the blow is large, so that it is not easy to break and lose, and the scraping time is prolonged. , to ensure the effect of fiber quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

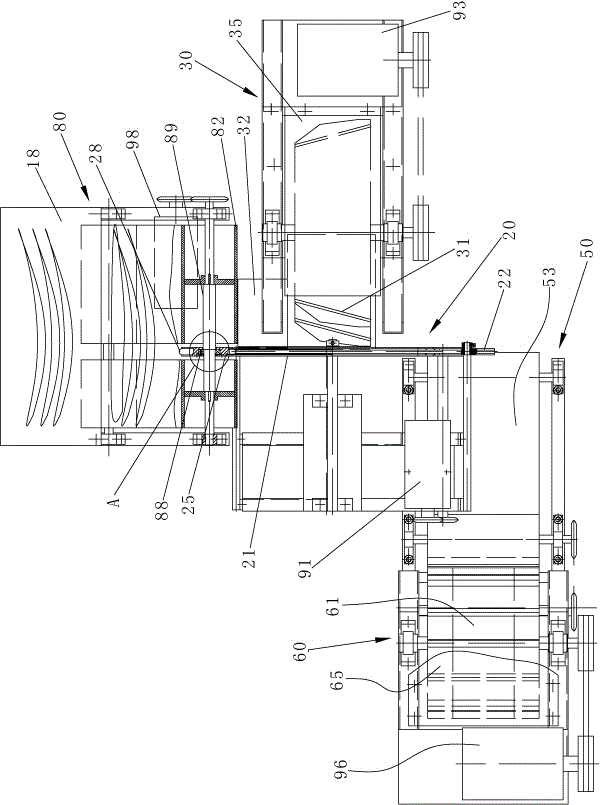

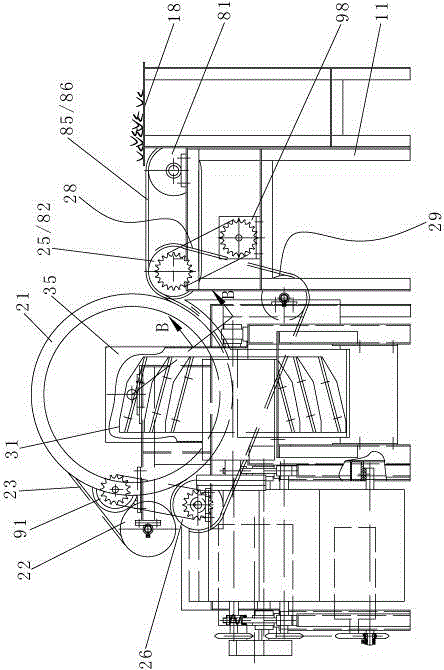

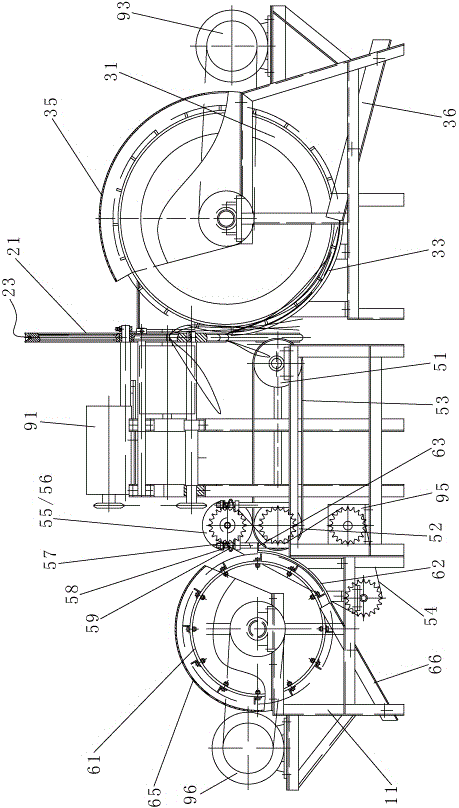

[0032] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown, the present invention a kind of two-way section feeding automatic hemp scraping machine, it comprises frame 11, horizontal feeding device 20, horizontal hemp scraping device 30, longitudinal feeding device 50, longitudinal hemp scraping device 60; The feeding device 20 comprises the main clamping hemp wheel 21 installed on the frame 11, the front clamping hemp wheel 25 parallel to the front lower side of the main clamping hemp wheel 21, and the rear lower side of the main clamping hemp wheel 21 parallel to the axis. The back clamping hemp wheel 26, tensioning around the clamping hemp O-shaped belt 28 of the front clamping hemp wheel 25 and the rear clamping hemp wheel 26, driving the main clamping hemp wheel 21, the front clamping hemp wheel 25 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com