Wire cutting machine

A cutting machine and wire technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of lack of consistency, reduced efficiency of distribution boxes, and irregularities, so as to ensure consistency and improve The effect of assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

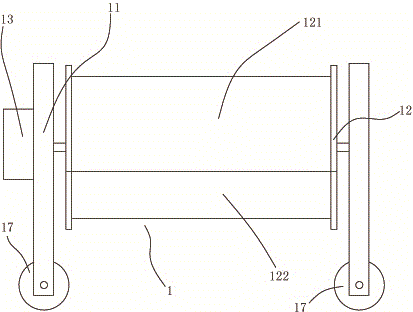

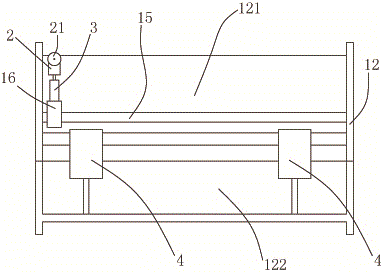

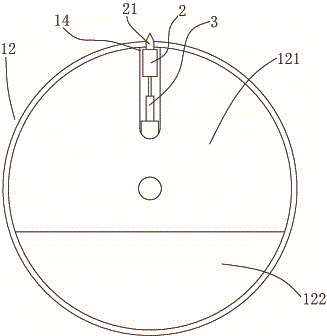

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1 to Figure 4 , wire cutting machine, including a winding device 1 and a cutting device 2, the winding device 1 includes a support 11 and a reel 12 arranged on the support 11, the reel 12 is connected with a first motor 13, the reel The barrel 12 is provided with an opening 14 in the axial direction, and a first slide rail 15 is arranged inside the reel 12, and a first slider 16 is arranged on the first slide rail 15, and a first slider 16 is arranged on the first slider 16. The cutting device 2, the cutting piece 21 of the cutting device 2 is located in the opening 14, the bottom of the bracket 11 is provided with a wheel 17, and the wheel 17 is connected to a second motor (not shown in the figure). The wire cutting machine with this structure drives the wheel 17 to rotate through the second motor to make the wire cutting machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com