Power transmission device for discharging mechanism of screen roller type counterflow cooler

A power transmission device and countercurrent cooling technology, applied in direct contact heat exchangers, feed, heat exchanger types, etc., can solve problems such as troublesome operation, manual adjustment of chains, etc., and achieve the effect of convenient maintenance and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments.

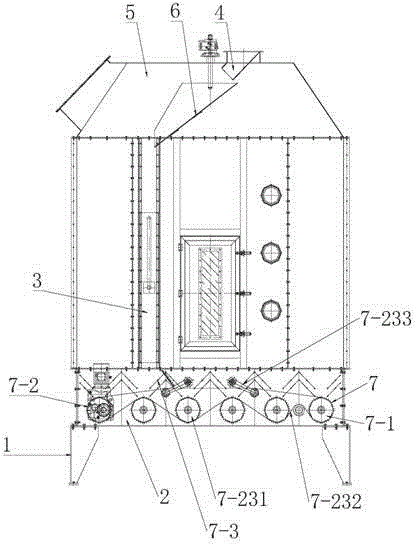

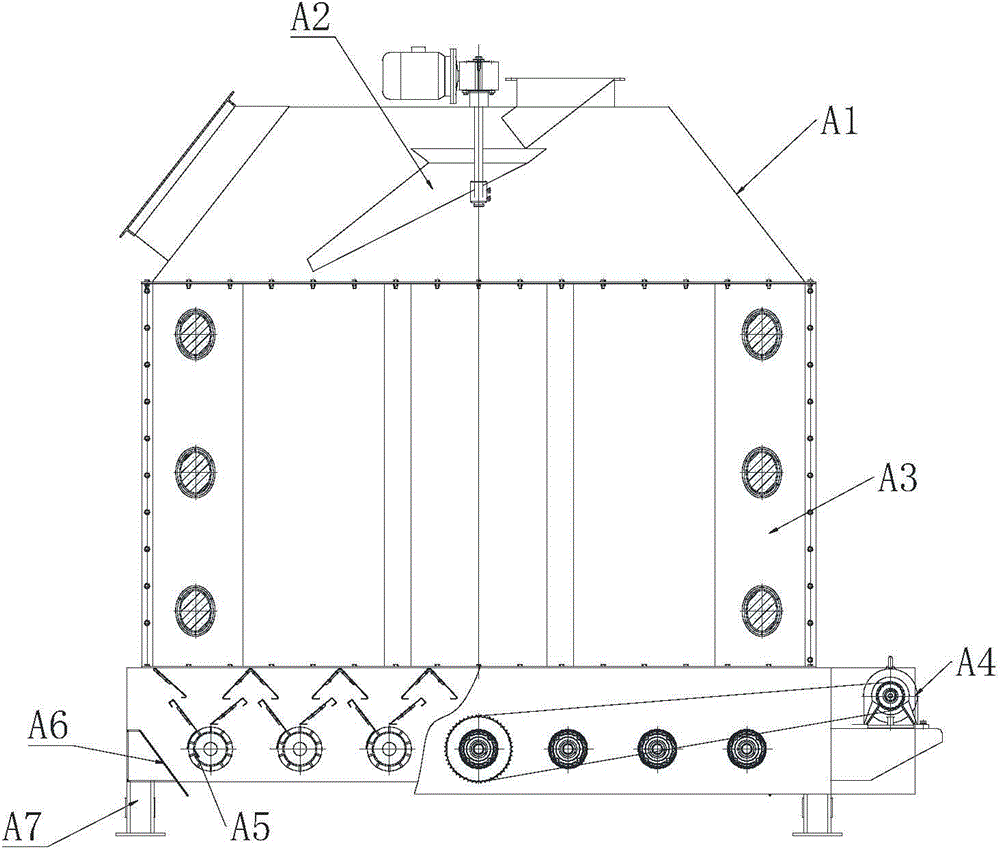

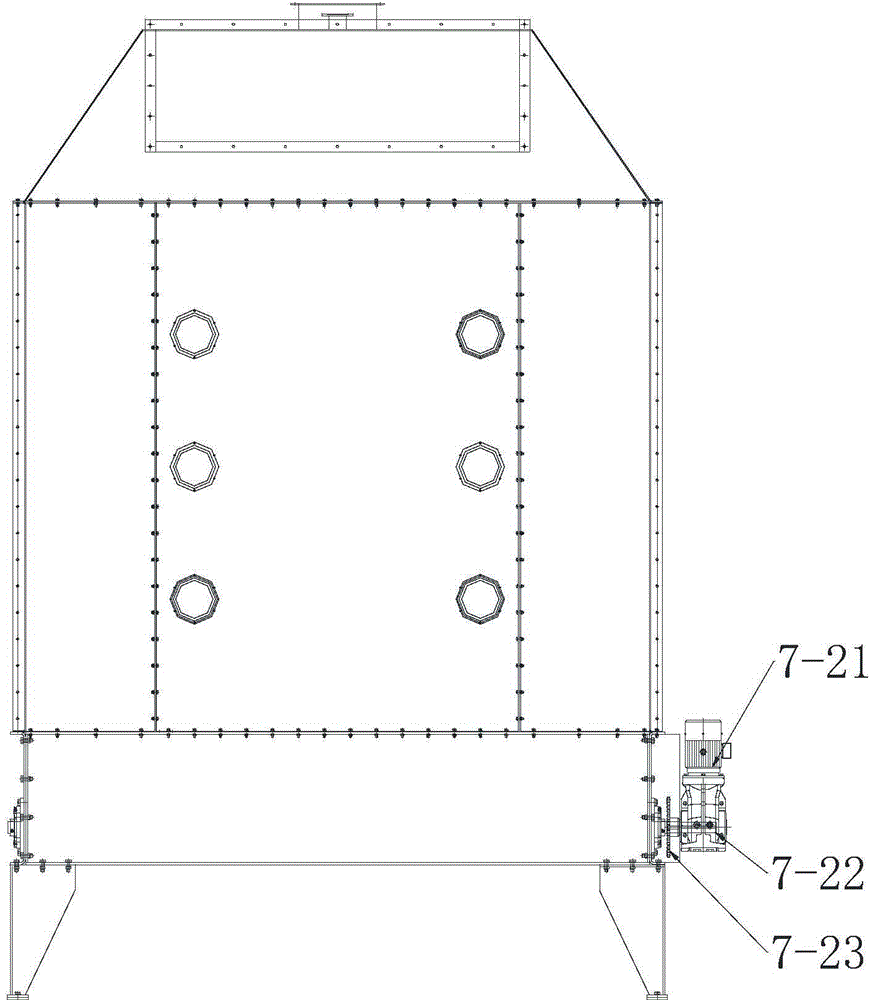

[0018] like Figure 1-Figure 5 As shown, the present invention is a power transmission device of a discharge mechanism, which is applied to a sieve roller type countercurrent cooler, wherein the sieve roller type countercurrent cooler includes a frame 1, a collection box 2, a cooling box 3, Feeder 4, air outlet top cover 5, bulk material device 6 and discharge mechanism 7, air outlet top cover 5 is arranged on the top of the cooling box, collection box 2 is arranged under the cooling box 3, collection box 2 is set on the frame 1, the discharge mechanism 7 is set in the collecting box 2, the feeder 4, the air outlet top cover 5, and the bulk material device 6 are respectively set above the cooling box, and the cooling box is rectangular. There are arc-shaped plates 8 for transition between the adjacent two-side box plates, and the arc-shaped pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com