Fruit grain solidification type yoghourt and preparation method thereof

A technology of coagulated yogurt and fruit granules, applied in milk preparations, dairy products, applications, etc., can solve the problems of poor flavor and taste, cumbersome operation, and product softening, and achieve the effect of improving taste and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

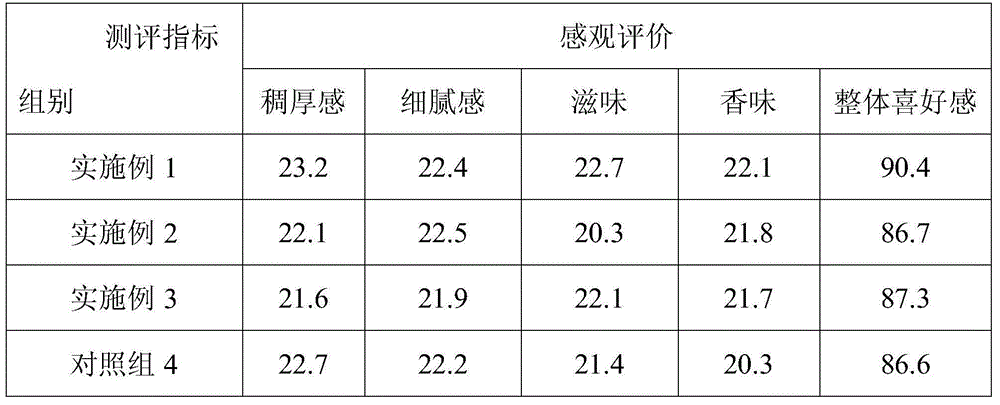

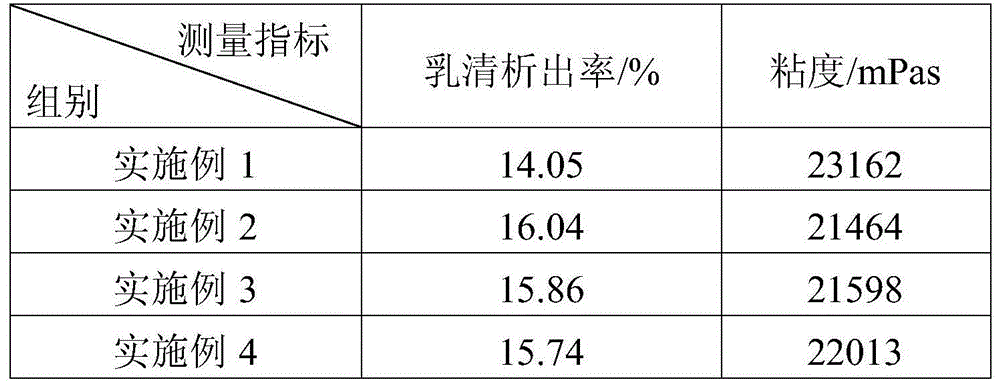

Examples

Embodiment 1

[0037] Weigh each raw material according to the following weights: white granulated sugar 75kg, whey protein powder 20kg, casein powder 1kg, cream 4.5kg, compound stabilizer 4kg, yellow peach fruit 80kg (5×5×5mm), raw milk 815.5kg .

[0038] Prepare fruit set yoghurt as follows:

[0039] (1) Clean milk: It will meet the inspection standard of fresh milk for yogurt process, the non-fat milk solids should not be less than 8.5%, no antibiotics are required for raw milk, and the bacteriostatic factor lysozyme cannot be detected; standard clean milk separator Separation and standardization of raw milk, cooling, standby;

[0040] (2) Mixing: Preheat 30% of the total weight of raw milk to 60°C, add casein powder and whey protein powder, stir for 8 minutes, and hydrate for 40 minutes; then add white sugar, cream, and compound stabilizer, and stir 8min, then add the remaining raw milk to obtain the mixture;

[0041] (3) Homogenization and pasteurization: preheat the mixture to 65°C ...

Embodiment 2

[0048] Weigh each raw material according to the following weights: white granulated sugar 80kg, whey protein powder 10kg, casein powder 2kg, cream 6kg, compound stabilizer 8kg, mango granules 60kg (5×5×5mm), raw milk 834kg.

[0049] Prepare fruit set yoghurt as follows:

[0050] (1) Clean milk: It will meet the inspection standard of fresh milk for yogurt process, the non-fat milk solids should not be less than 8.5%, no antibiotics are required for raw milk, and the bacteriostatic factor lysozyme cannot be detected; standard clean milk separator Separation and standardization of raw milk, cooling, standby;

[0051] (2) Mixing: Preheat 20% of the total weight of raw milk to 50°C, add casein powder and whey protein powder, stir for 10 minutes, and hydrate for 20 minutes; then add white sugar, cream, and compound stabilizer, and stir 10min, then add the remaining raw milk to obtain the mixture;

[0052] (3) Homogenization and pasteurization: preheat the mixture to 60°C for a ho...

Embodiment 3

[0059] Weigh each raw material according to the following weights: white granulated sugar 60kg, whey protein powder 25kg, casein powder 0.5kg, cream 4kg, compound stabilizer 5kg, pineapple fruit pieces 90kg (5×5×5mm), raw milk 815.5kg .

[0060] Prepare fruit set yoghurt as follows:

[0061] (1) Clean milk: It will meet the inspection standard of fresh milk for yogurt process, the non-fat milk solids should not be less than 8.5%, no antibiotics are required for raw milk, and the bacteriostatic factor lysozyme cannot be detected; standard clean milk separator Separation and standardization of raw milk, cooling, standby;

[0062] (2) Mixing: Preheat 40% of the total weight of raw milk to 60°C, add casein powder and whey protein powder, stir for 5 minutes, and hydrate for 50 minutes; then add white sugar, cream, and compound stabilizer, and stir 5min, then add the remaining raw milk to obtain the mixture;

[0063] (3) Homogenization and pasteurization: preheat the mixture to 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com