Multi-stage transmission

A technology of transmission and automatic transmission, applied in the direction of vehicle gearbox, multi-gear ratio transmission device, transmission device, etc., can solve the problem of unsuitable front lateral system installation, etc., to achieve driving comfort, small size, and improved consumption reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

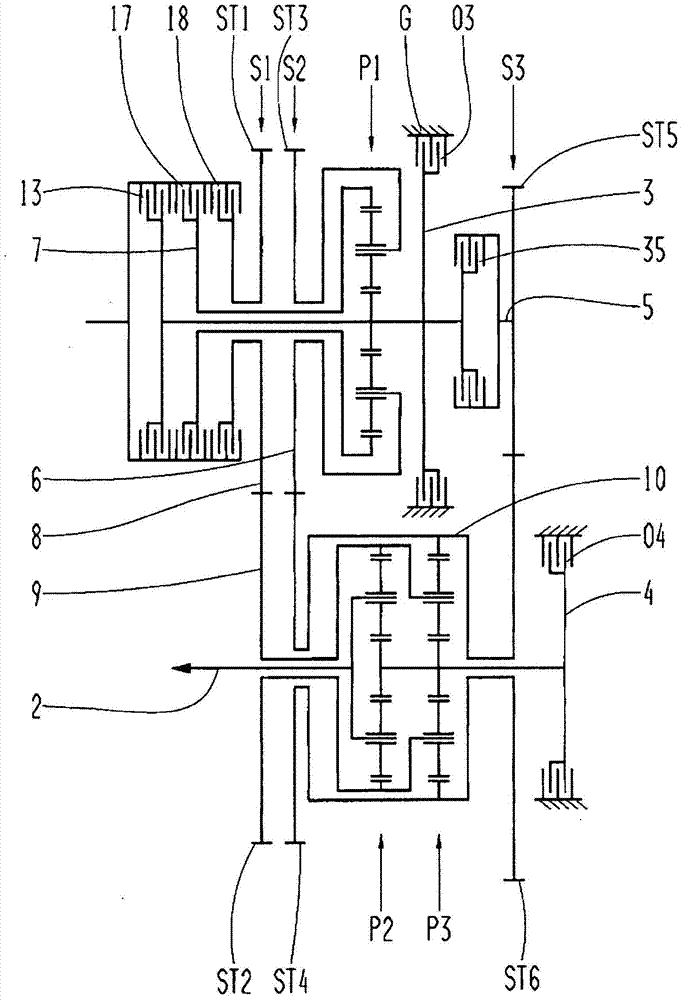

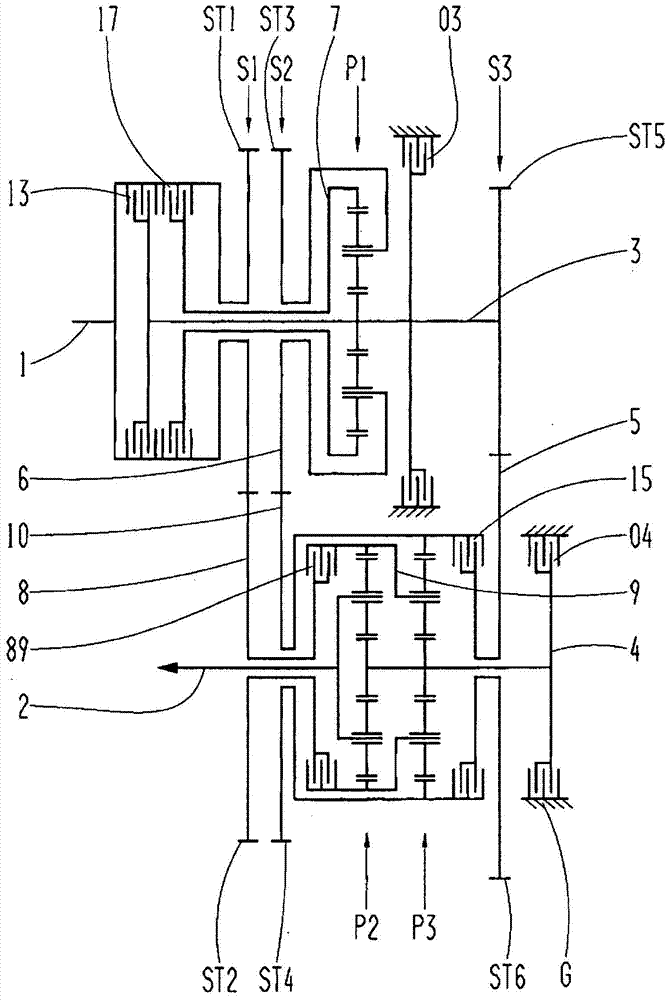

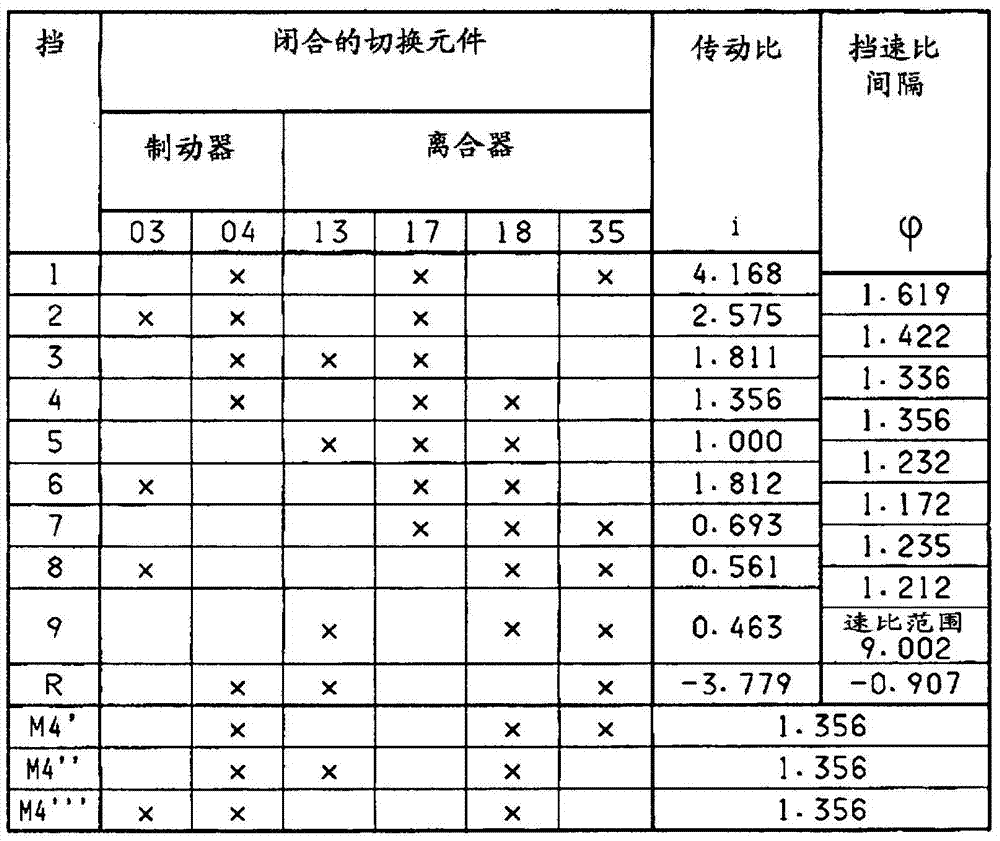

[0035] exist figure 1 shows a multi-stage transmission according to the invention, which comprises a first planetary gear set P1, a second planetary gear set P2 and a third planetary gear set P3, wherein the first planetary gear set P1 is coaxial arranged on a first axis defined by the drive shaft 1 , while the second and third planetary gear sets P2 , P3 are arranged coaxially on a second axis defined by the driven shaft 2 and arranged parallel to the first axis.

[0036] In the example shown, the planetary gear sets P1 , P2 , P3 are configured as negative planetary gear sets. Here, at least one planetary gear set of the transmission can be configured as a positive gear ratio planetary gear when the planetary carrier connection and the ring gear connection are replaced at the same time and the value of the fixed gear ratio is increased by 1 compared to the embodiment as a negative gear ratio planetary gear set Group.

[0037] as by figure 1 It can be seen that six shift el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com