Split type direct-current charging piles for electric automobiles, system and method

A technology for DC charging piles and electric vehicles, which is applied in the fields of electric vehicle charging technology, electric vehicles, secondary battery charging/discharging, etc., and can solve the problems of low utilization rate of charging piles at night, large cabinet footprint, and large average power, etc. problem, to achieve the effect of flexible charging combination, small footprint and low power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

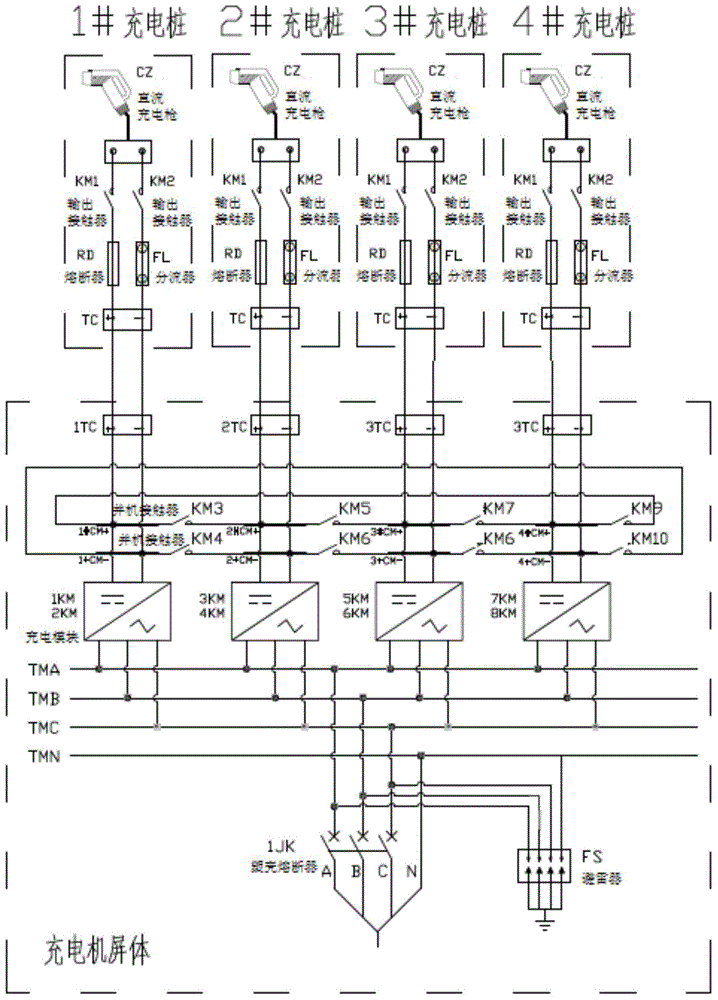

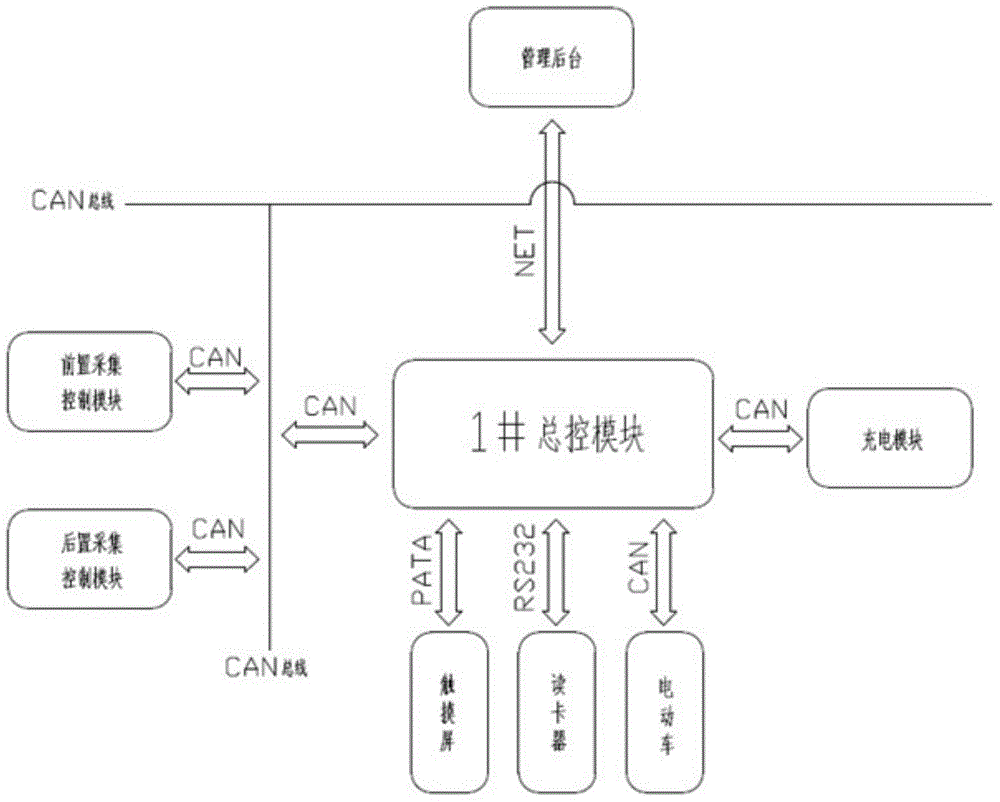

[0053] Such as figure 1 As shown, taking 4 charging piles with a single pile power of 30KW as an example to form a group (but not limited to 4, multiple piles can be paralleled according to actual needs), the core technology of charging piles to realize group parallel work is explained.

[0054] A split DC charging pile, system and method for an electric vehicle, including a charger screen and a DC charging pile;

[0055] The screen body of the charger includes the main switch of AC incoming line, surge arrester, AC bar, grouped charging module, 1# positive and negative bus bar, 2# positive and negative bus bar, 3# positive and negative bus bar, 4# positive and negative bus bar, and parallel Machine contactor, TC terminal, discharge relay, discharge resistor, charging module communication switching intermediate relay, temperature controller, filter fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com