Warehouse management system with multi-guide-vehicle dispatching and distribution function

A warehouse management system, dispatching and distribution technology, applied in the direction of data processing applications, instruments, logistics, etc., can solve the problems of uncollected data, undiscovered, etc., and achieve the effect of improving automation level and operating efficiency, and optimizing working methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

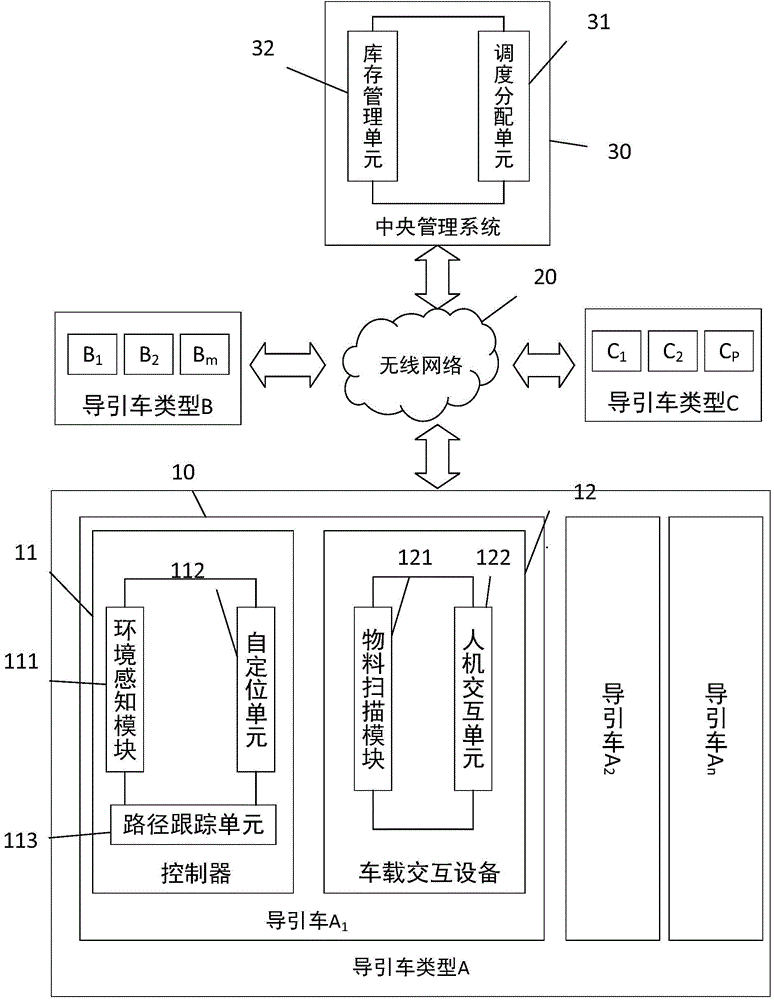

[0031] This embodiment provides a warehouse management system with multi-guided vehicle scheduling and distribution functions, including a central management system and at least one autonomous guided vehicle:

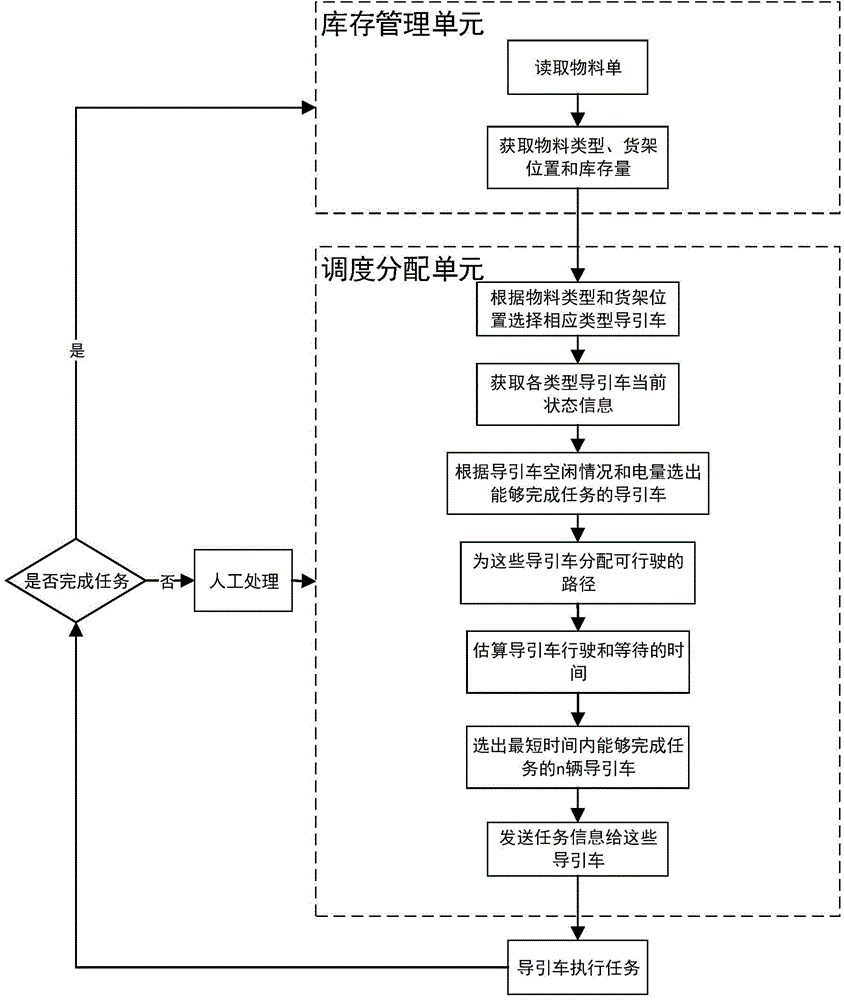

[0032] The central management system mainly includes dispatching and distribution units and inventory management units. The inventory management unit reads the bill of materials, obtains the type of the material, the position of the shelf in the warehouse, the position of the material on the shelf, and the inventory of the material, and sends this information to the dispatching and allocating unit. An environmental map of the entire warehouse is stored in the scheduling allocation unit. The scheduling and distribution unit selects the corresponding type of guided vehicle (high-level picking type, low-level picking type or autonomous forklift) according to the type of material (scattered material or pallet material) and the position of the shelf in the warehouse as well ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com