Electric cylinder loading overlapping type force standard machine

A superimposed, electric cylinder technology, applied in the direction of calibration/testing of force/torque/power measuring instruments, measuring devices, instruments, etc., can solve problems such as inappropriate methods, low detection accuracy, and high energy consumption, and achieve simple structure The effect of stability, high measurement accuracy and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

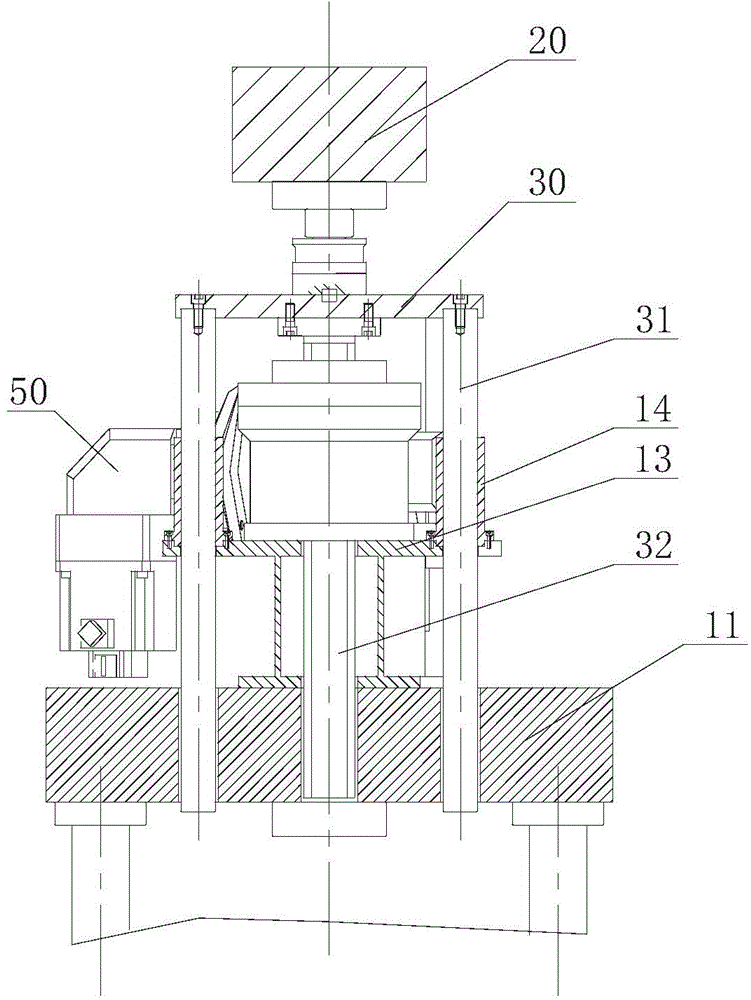

[0023] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

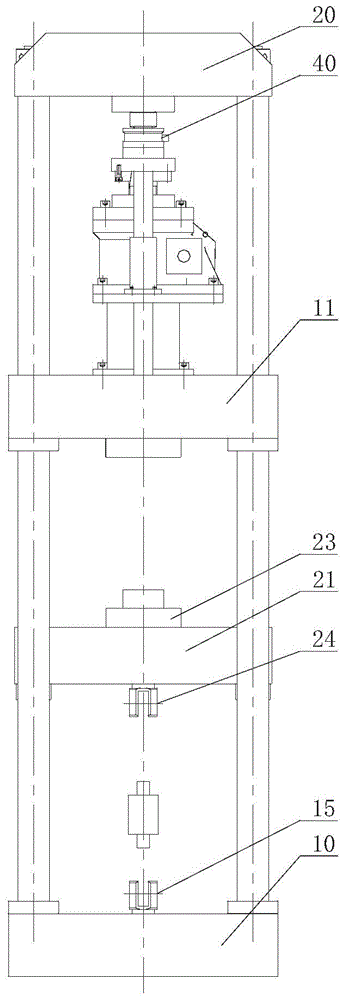

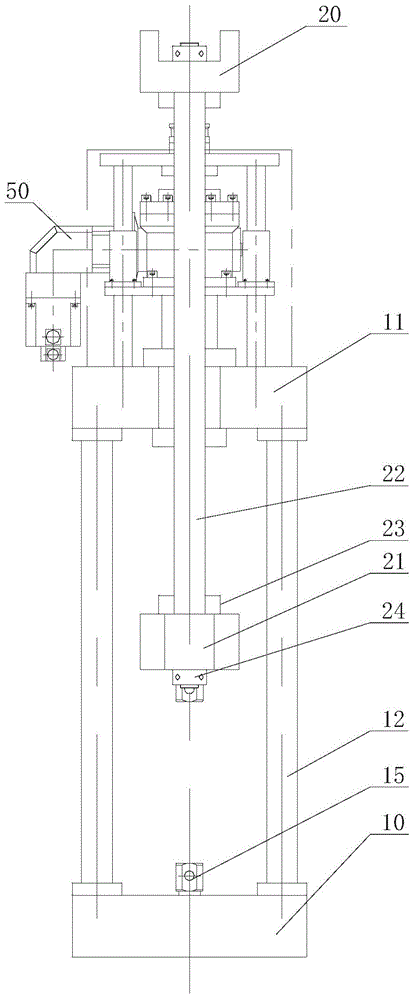

[0024] In order to achieve the purpose of the present invention, as Figure 1 to Figure 3 As shown, in one of the embodiments of the present invention, an electric cylinder loading superimposed force standard machine is provided, including:

[0025] The support includes a horizontally arranged base 10 and an upper support base 11, the upper support base 11 is arranged above the base 10 and is connected by a plurality of columns 12 therebetween;

[0026] Reverse frame comprises reverse frame upper beam 20, reverse frame lower beam 21 and a plurality of reverse frame connecting rods 22, reverse frame upper beam 20, reverse frame lower beam 21 are horizontally arranged and between the two through reverse Connect to the frame connecting rod 22, the upper beam 20 of the reverse frame is arranged on the top of the upper support base 11, the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com