A differential gear shaft assembly equipment

A technology for assembling equipment and rotating shafts, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low degree of automation, large manpower consumption, and affecting product quality, so as to improve the insertion accuracy and ensure the moving direction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

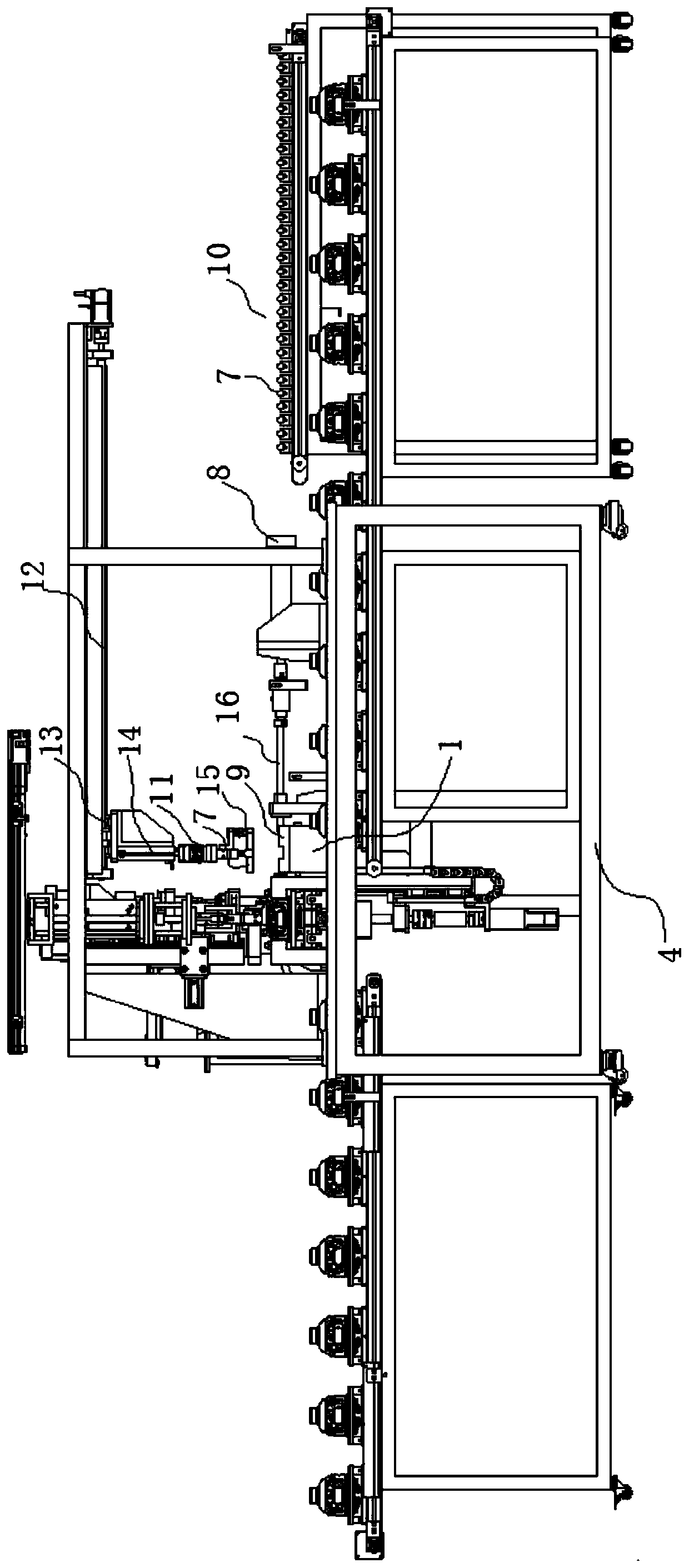

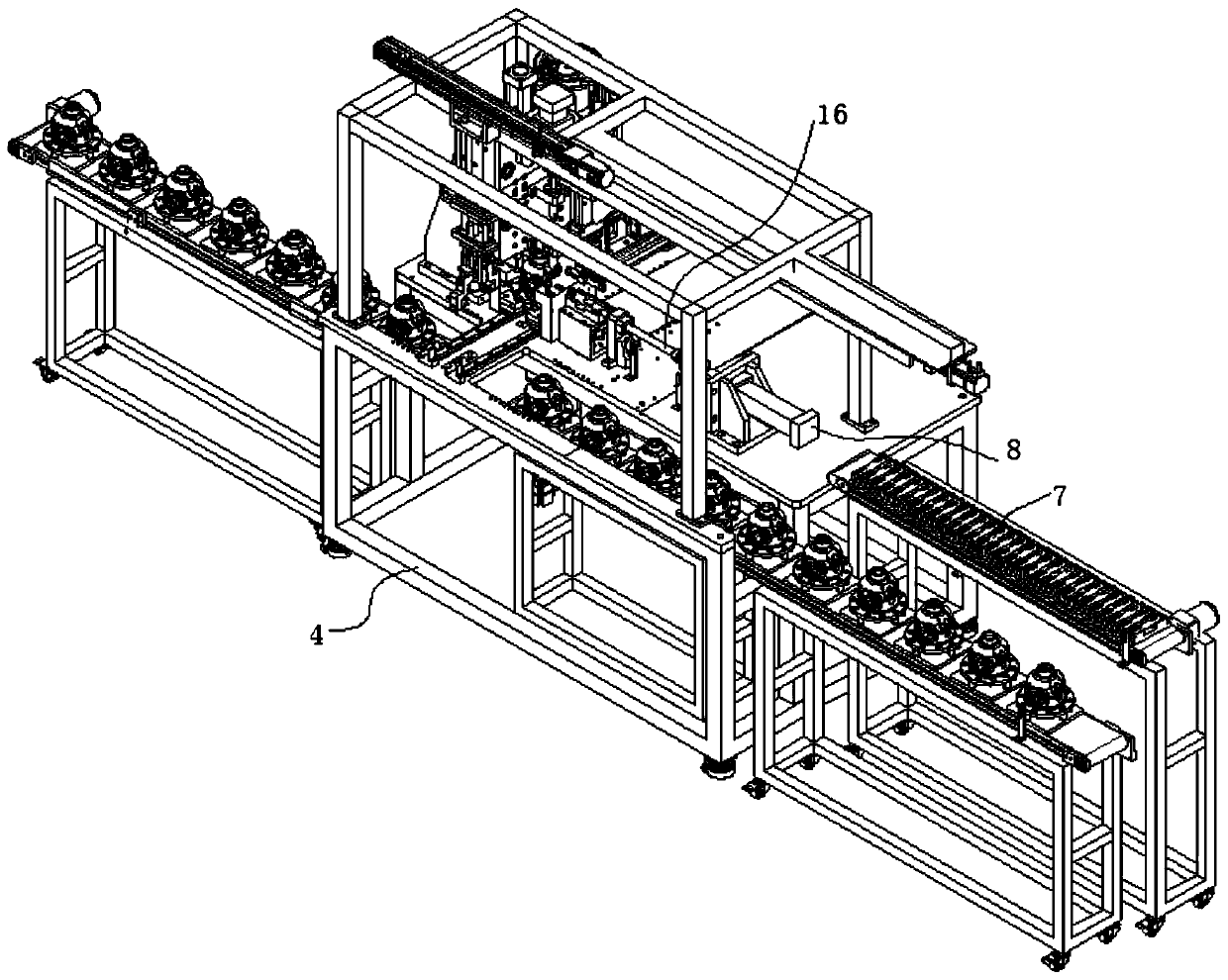

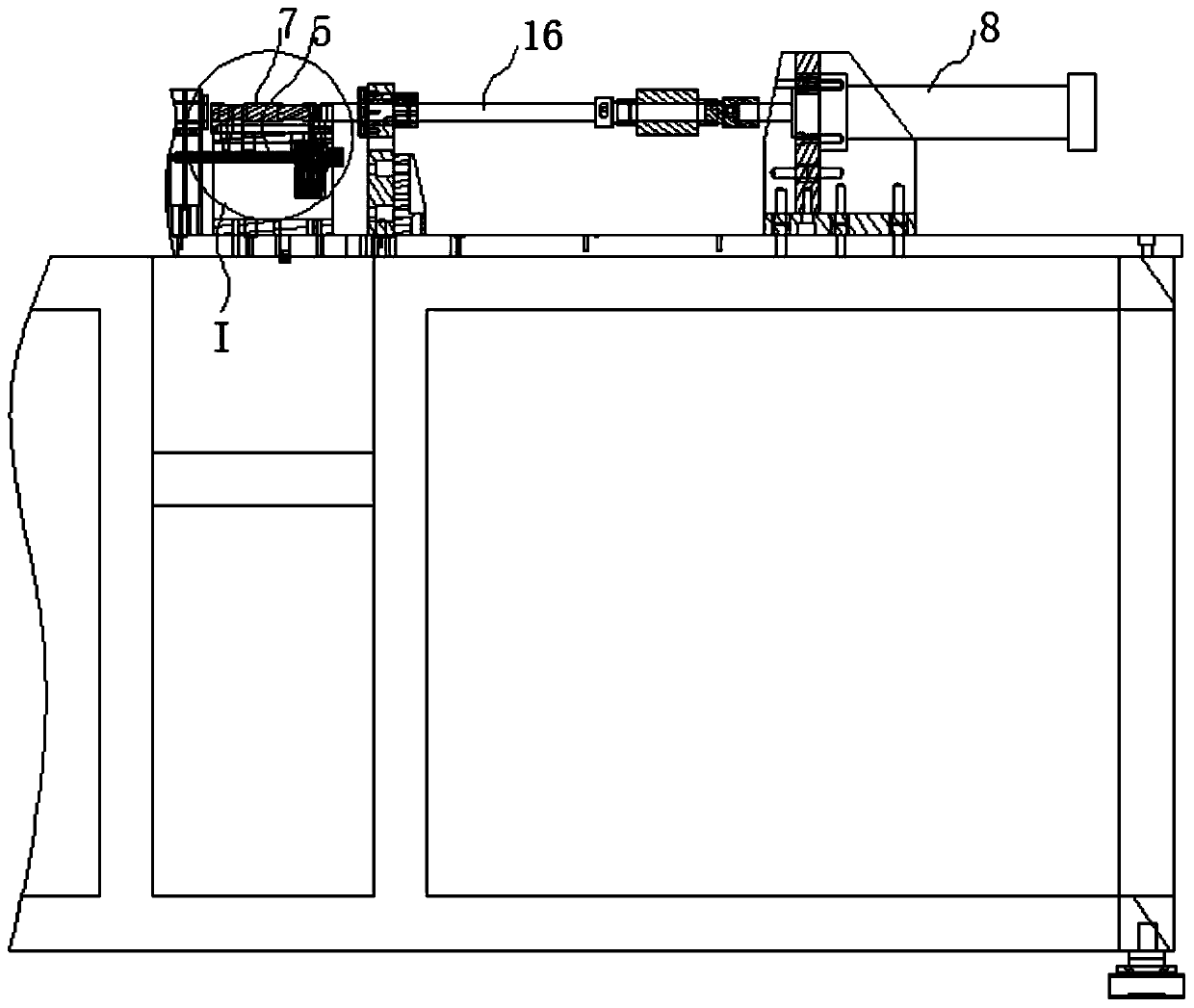

[0018] Such as figure 1 and to Figure 4 As shown, a differential rotating shaft assembly equipment includes an assembly seat 1 and a movable seat 2, the assembly seat 1 is provided with a guide hole 3, and the guide hole 3 is directly opposite to the rotating shaft installation hole on the differential , the frame 4 is provided with a movable seat guide rail 5, and the movable seat 2 is movably mounted on the movable seat guide rail 5, and the movable seat 2 is provided with a limit pin 6, and the limit pin 6 and the movable seat There is a lifting drive device between the seats 2, the limit pin 6 can be inserted into the pin hole 17 on the rotating shaft 7, the rotating shaft assembly equipment also includes a rotating shaft pushing mechanism, and the rotating shaft pushing mechanism includes a cylinder 8 , the cylinder piston rod 16 is aligned with the rear end face of the rotating shaft 7, and also includes a limit pin lift control device, the limit pin lift control devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com