Coal seam group well-ground combined layered fracturing and combined layer drainage method

A technology of layer fracturing and coal seam group, applied in gas discharge, mining fluid, mining equipment and other directions, can solve the problems of multi-coal seam grouping, fracturing failure, interlayer interference, etc., to achieve broad application prospects and reduce well drilling costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

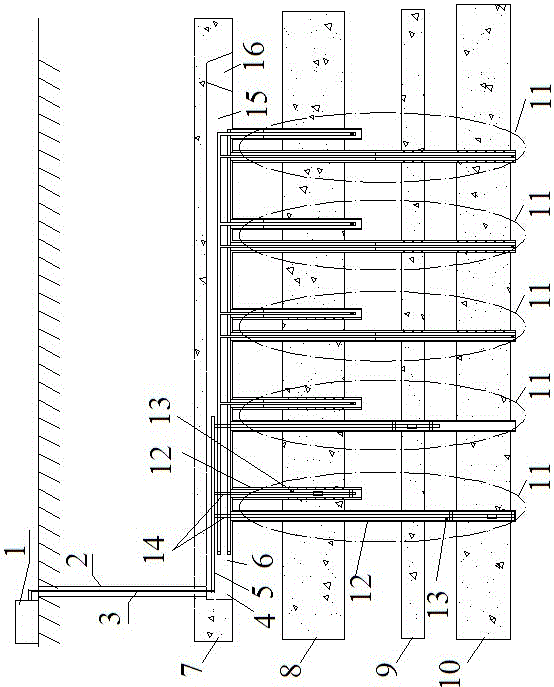

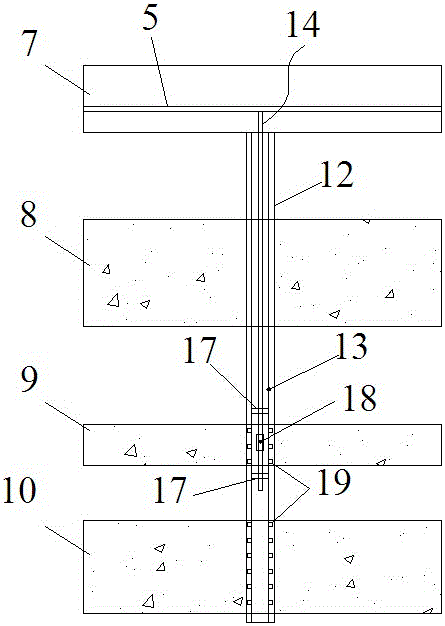

[0014] Depend on Figure 1-Figure 5 The shown coal seam group well-ground combined layered fracturing and combined layer drainage method is aimed at the gas drainage of multi-coal seam groups. In this example, there are four coal seams, and the four coal seams are top coal seam 7, The first coal seam 8, the second coal seam 9 and the third coal seam 10, the coal thickness of these four coal seams are respectively 3m, 6.2m, 2.3m, 4.6m respectively, and this mine is down mining, and it comprises the following steps:

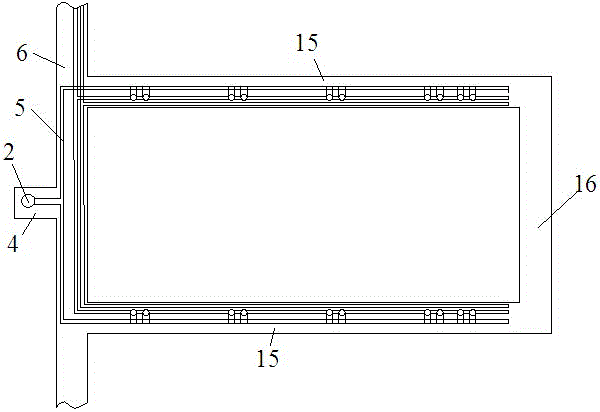

[0015] (1) Since the top coal seam 7 has no risk of outburst, the top coal seam 7 is mined first, and roadways are excavated in the top coal seam 7. , cut eye 16 and along groove 15 are prior art, so do not describe in detail). The extraction roadway is a parallel channel 15 in the top coal seam 7 . Of course, the present invention is not limited to the above-mentioned form, and the drainage roadway can also be the uphill 6 or the cutout 16 according to the actua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com