Vertex-aligning buttress balancing plate type cutting supporting block device

A weighing and cutting technology, applied in excavation, underwater structures, buildings, etc., can solve the problems of more excavation operations, construction difficulties, consumption of large amounts of concrete and stone, etc., to improve environmental protection effects and performance, and reduce human labor. Strength, effect of increasing slip resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0023] This embodiment provides a buttress counterweight plate type cutting supporting device.

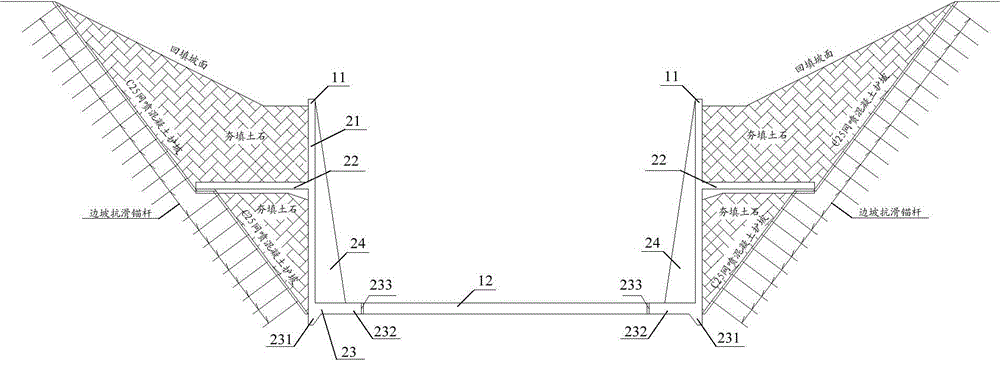

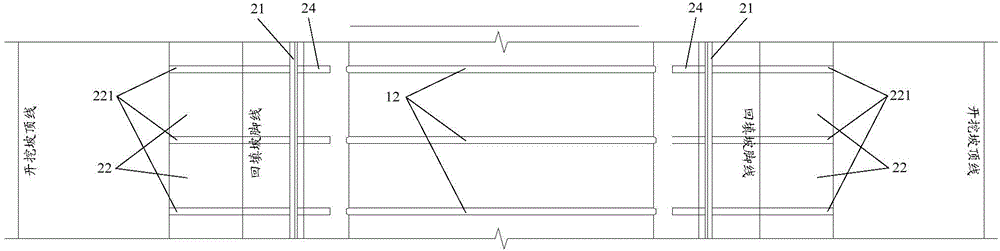

[0024] figure 1 It is a cross-sectional schematic diagram of the buttress counterweight plate type road cutting support device in the embodiment of the present invention. figure 2 It is a top view of the buttress counterweight plate type road cutting support device in the embodiment of the present invention. Such as figure 1 with figure 2 As shown, the buttress counterweight plate type road cutting supporting device in the embodiment of the present invention mainly includes:

[0025] The supporting retaining walls 11 arranged on both sides of the road and extending along the road direction and the inter-wall top beams 12 arranged between two opposite s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com