Spicy spice for kretek blasting bead, preparation method and application thereof

A technology of spicy essence and popping beads, which is applied in the direction of essential oil/fragrance, tobacco, application, etc., can solve the problems of affecting consumers' sensory experience and aggravating chemical smell, and achieves small incision, simple preparation method and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. Pretreatment of raw materials: Weigh the clove buds, wash them, dry them in the shade, then crush them, pass through a 100-150 mesh sieve, and set aside;

[0024] 2. Soaking: add 75% ethanol that is 25 times the weight of clove bud powder and soak for 24 hours;

[0025] 3. Ultrasonic extraction: Ultrasonic time is 60min, ultrasonic power is 40w, filter, and the filtrate is refluxed three times at 80°C for separation to obtain clove bud oil;

[0026] 4. Dilute the above thymol with propylene glycol to a 10% solution, shake well until completely dissolved, and set aside;

[0027] 5. Dilute the above-mentioned vanillin with propylene glycol to a 10% solution, shake well until completely dissolved, and set aside;

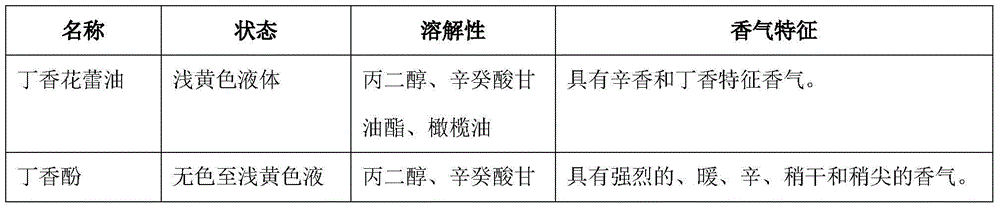

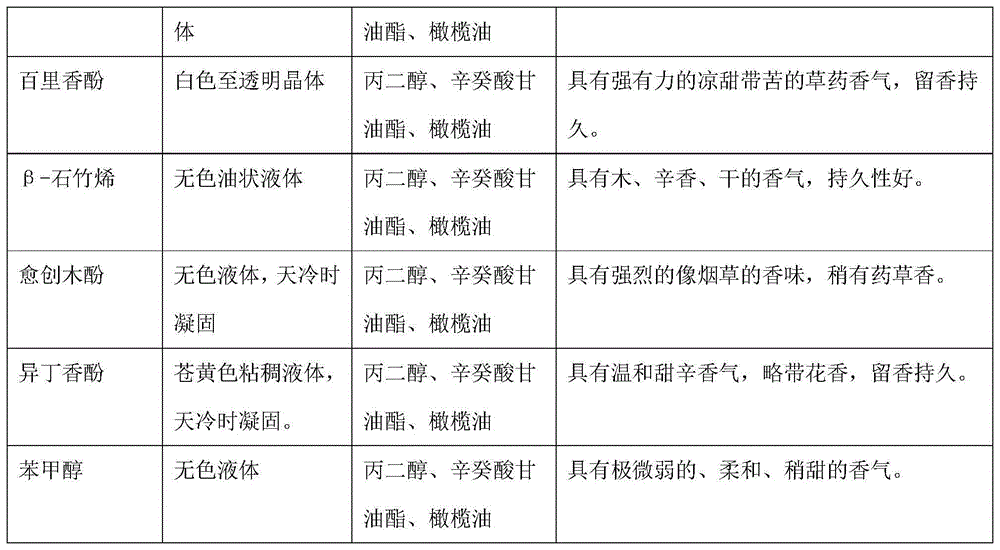

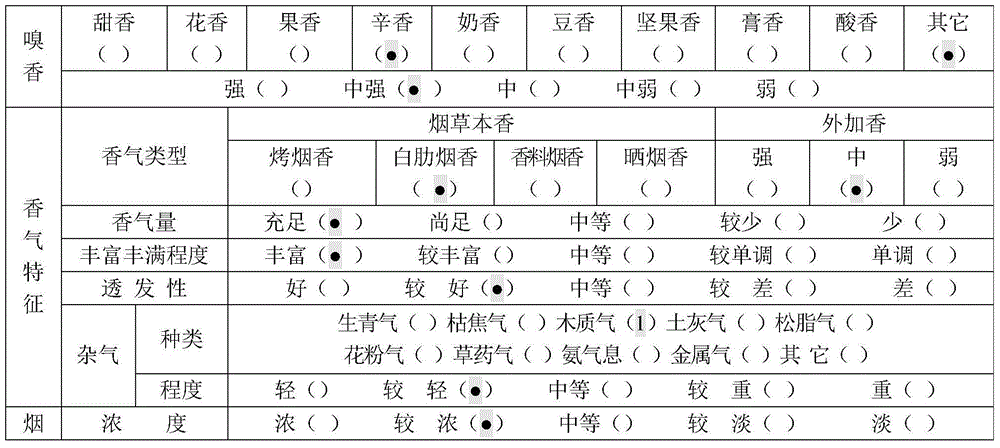

[0028] 6. The parts by weight are 3 parts of clove bud oil, 0.8 part of eugenol, 0.2 part of 10% thymol, 0.5 part of β-caryophyllene, 0.5 part of guaiacol, 1.0 part of isoeugenol, 10% pandan Mix 3 parts of benzyl alcohol, 0.7 part of benzyl alcohol and 90.3 ...

Embodiment 2

[0030] 1. Pretreatment of raw materials: Weigh the clove buds, wash them, dry them in the shade, then crush them, pass through a 100-150 mesh sieve, and set aside;

[0031] 2. Soaking: add 75% ethanol that is 25 times the weight of clove bud powder and soak for 36 hours;

[0032] 3. Ultrasonic extraction: Ultrasonic time is 60min, ultrasonic power is 40w, filter, and the filtrate is refluxed three times at 80°C for separation to obtain clove bud oil;

[0033] 4. Dilute the above thymol with propylene glycol to a 10% solution, shake well until completely dissolved, and set aside;

[0034] 5. Dilute the above-mentioned vanillin with propylene glycol to a 10% solution, shake well until completely dissolved, and set aside;

[0035] 6. The parts by weight are 2 parts of clove bud oil, 0.5 part of eugenol, 0.1 part of 10% thymol, 0.8 part of β-caryophyllene, 0.8 part of guaiacol, 0.5 part of isoeugenol, 10% pandan 1 part of benzyl alcohol, 0.5 part of benzyl alcohol and 93.8 parts...

Embodiment 3

[0037] 1. Pretreatment of raw materials: Weigh the clove buds, wash them, dry them in the shade, then crush them, pass through a 100-150 mesh sieve, and set aside;

[0038] 2. Soaking: add 75% ethanol that is 25 times the weight of clove bud powder and soak for 30 hours;

[0039] 3. Ultrasonic extraction: Ultrasonic time is 60min, ultrasonic power is 40w, filter, and the filtrate is refluxed three times at 80°C for separation to obtain clove bud oil;

[0040] 4. Dilute the above thymol with propylene glycol to a 10% solution, shake well until completely dissolved, and set aside;

[0041] 5. Dilute the above-mentioned vanillin with propylene glycol to a 10% solution, shake well until completely dissolved, and set aside;

[0042] 6. The parts by weight are 5 parts of clove bud oil, 1.0 part of eugenol, 0.3 part of 10% thymol, 0.2 part of β-caryophyllene, 0.2 part of guaiacol, 0.8 part of isoeugenol, and 10% pandan 5 parts of benzyl alcohol, 1.0 part of benzyl alcohol and 86.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com