Industrialized production method of reed and wood-plastic composite material

A technology of wood-plastic composite material and production method, which is applied in the field of factory production of reed wood-plastic composite material, can solve the problems of residual waste, rising cost, difficult composite materials, etc., and achieves simple steps, easy implementation, and huge demand effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

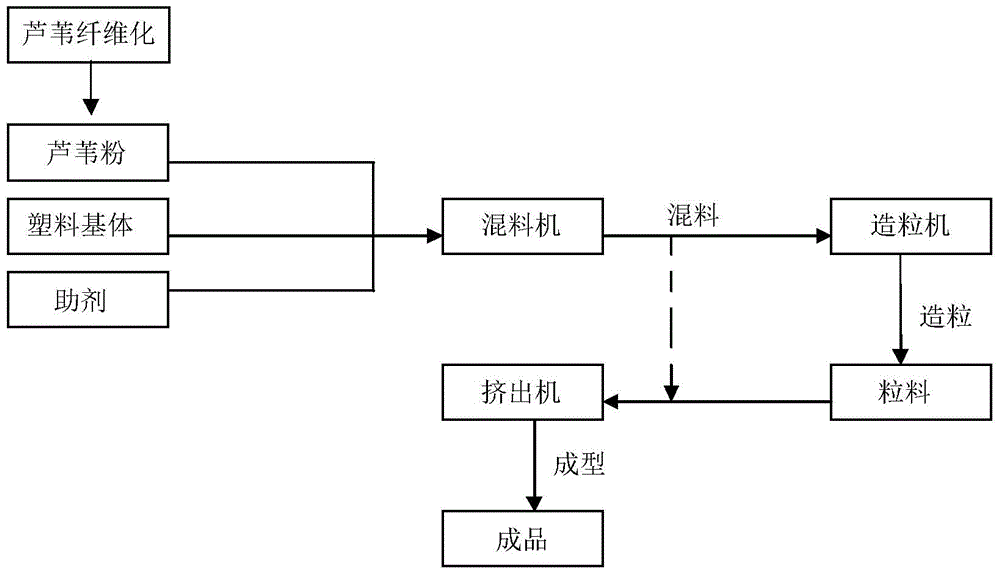

[0035] Such as figure 1 As shown, the factory production method of the reed wood-plastic composite material in this embodiment includes:

[0036] The first step, reed fiberization: the reed raw material is made into fibrous reed powder by steam explosion method or screw extrusion micro-carbonization method.

[0037] The steam explosion method includes: putting reed raw materials into a cooking blaster, feeding steam to maintain a preset steam pressure in the cooking blaster; using a preset pressure stabilization time and a preset blasting time to implement cooking blasting on the reed raw materials; After the product is dried, it is finely pulverized, and the diameter of the obtained particles is less than 0.42mm or the obtained particle mesh is greater than 60 meshes; after that, the obtained particles are dried until the water weight percentage is less than 9%, and the fibrous reed powder is obtained. Among them, the preset steam pressure is 1.2-5.0MPa, the preset pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com