Mechanical transmission arm for manufacturing automobile lamp shade

A transmission arm and lampshade technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of lampshade rupture, waste of installation time, and reduce work efficiency, and achieve the effect of increasing lateral accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

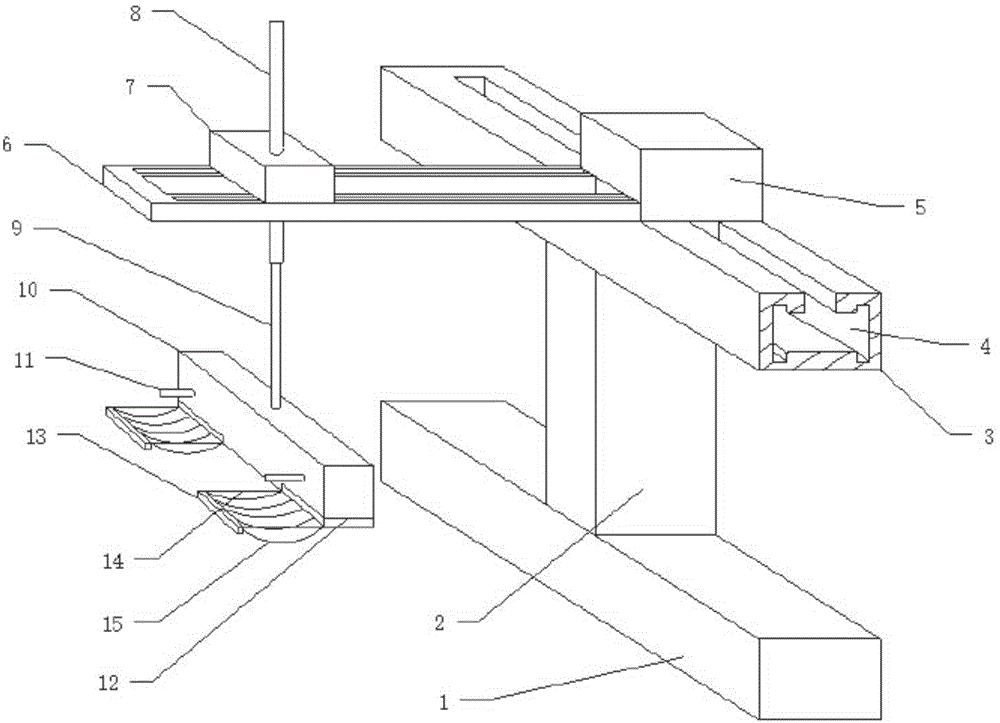

[0024] Such as figure 1 As shown, a mechanical transfer arm for the manufacture of automobile lampshades includes a base 1 and a support 2 arranged on the base 1, and the support 2 is provided with a sliding bar 3, and the a sliding bar 3 A chute 4 is provided on the top, and a sliding sliding seat 5 is provided in the a chute 4, wherein the sliding seat 5 slides in the a chute 4 provided by the a sliding rod 3, and the sliding seat 5 can be realized. lateral movement.

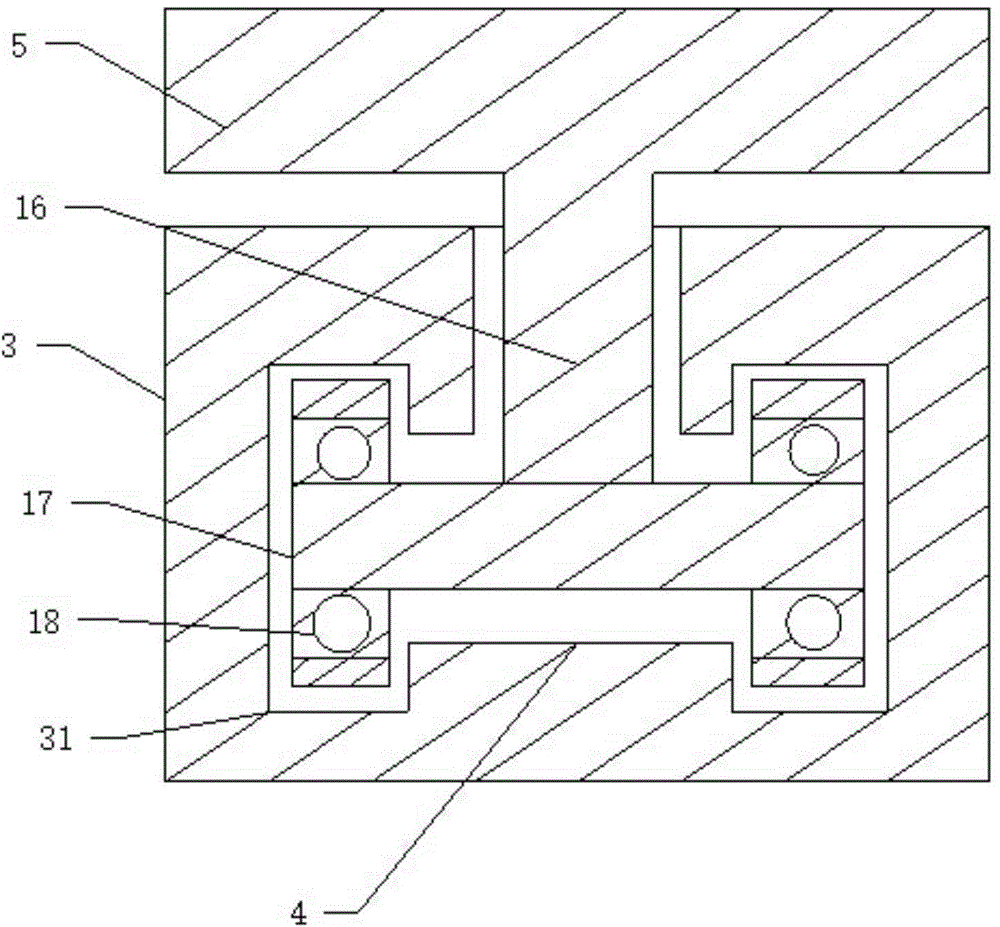

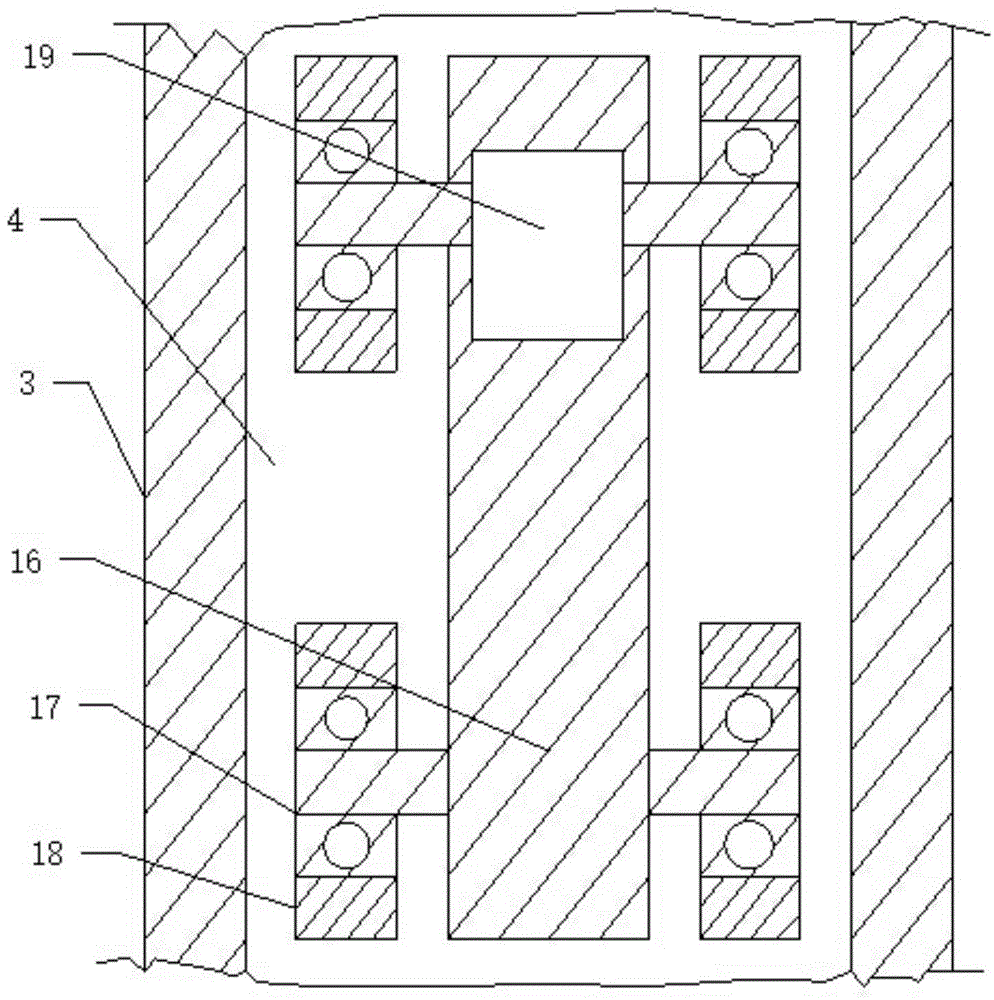

[0025] Such as figure 2 and image 3 As shown, the a chute 4 is in the shape of an "H", and a sliding seat connecting frame 16 is connected to the sliding seat 5, and the two ends of the sliding seat connecting frame 16 respectively include a motor 19 with a The rotating shaft 17 of driving and a rotating shaft 17 that is fixed on the described sliding seat connecting frame 16, the two ends of described rotating shaft 17 respectively comprise a roller 18 that is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com