A briquetting machine device for processing thick high-strength steel and its application

A high-strength steel, briquetting machine technology, applied in punching machines, presses, manufacturing tools, etc., can solve problems such as affecting the production of high-strength steel, disrupting, increasing the pressure on repair costs, avoiding equipment modification and improvement, reducing Production cost, the effect of avoiding slow production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

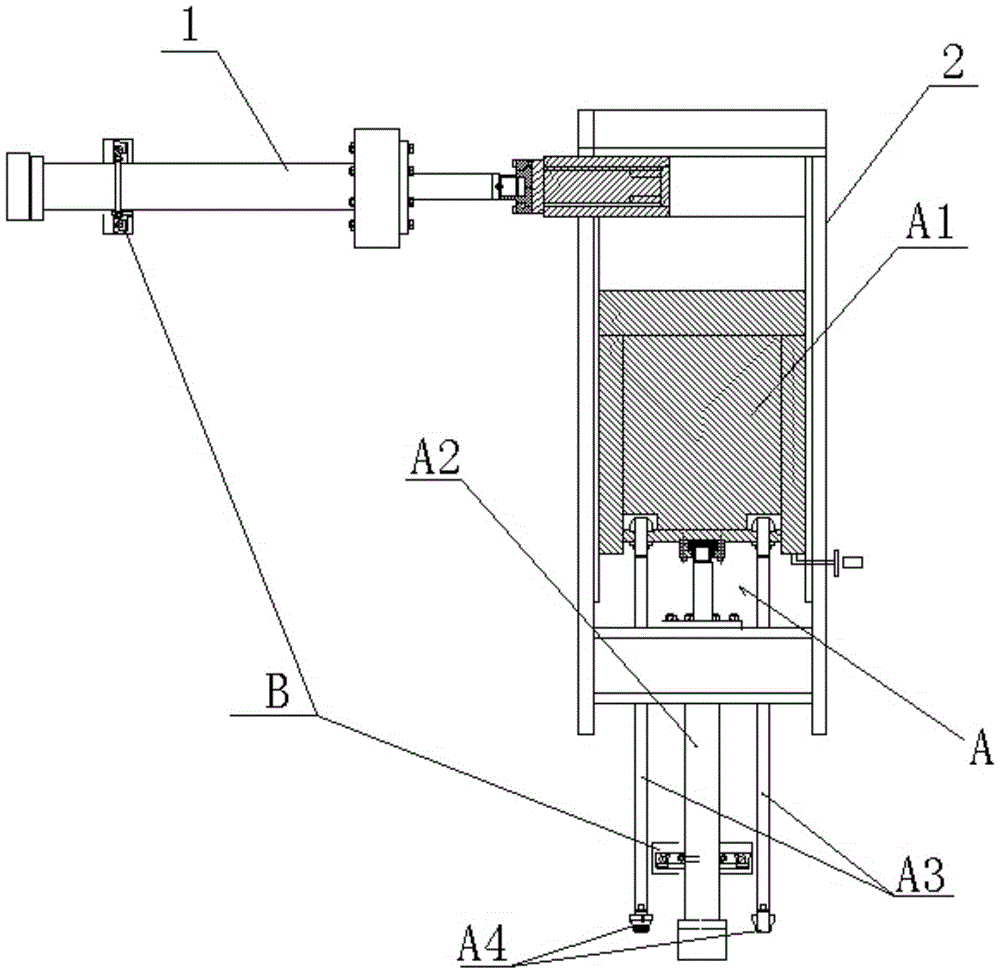

[0053] Such as Figure 1 to Figure 2 As shown, a briquetting machine device for processing thick material and high-strength steel includes a briquetting machine chamber 2 with a preformed oil cylinder assembly 1 arranged on one side, and a briquetting device assembly that can move up and down is arranged in the briquetting machine chamber A. The briquetting assembly presses the trimmed material in the material chamber of the briquetting machine into blocks, and then is pushed out of the material chamber of the briquetting machine by the preformed oil cylinder assembly;

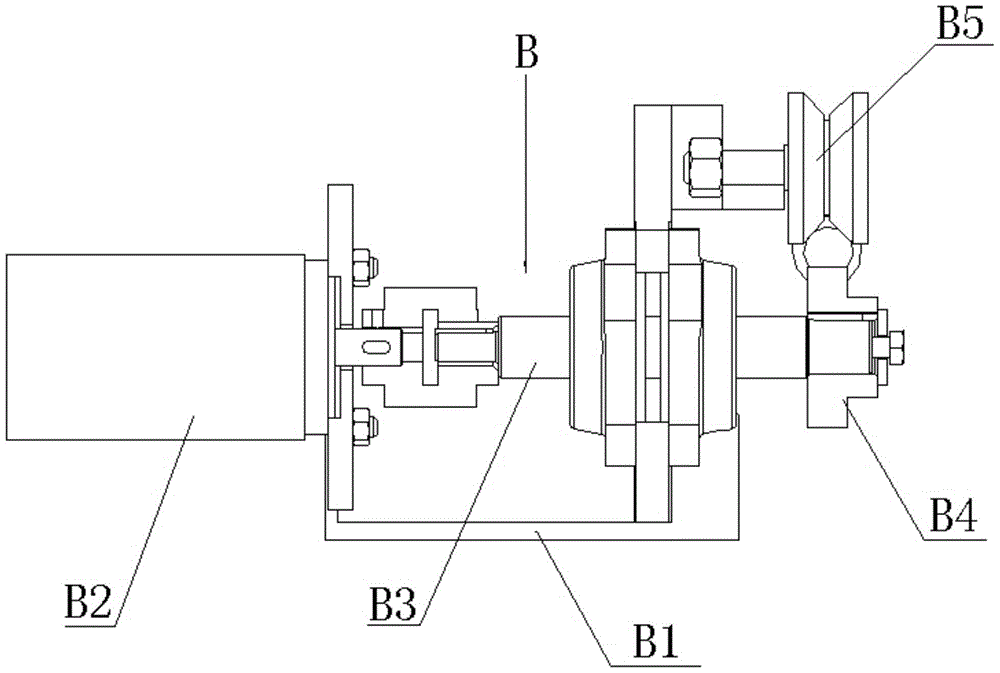

[0054] A speed monitoring device B is respectively arranged on the rack of the preforming oil cylinder assembly 1 and the rack of the oil cylinder of the briquetting device assembly A.

[0055] The briquetting device assembly A includes a top block A1, a jacking cylinder A2, a limit rod A3 and a positioning nut A4, wherein the top block is closely attached to the arch liner inside the material chamber 2 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com