Automatic nylon fabric laminating system

A nylon wrapping and laminating system technology is applied in the field of tire manufacturing, which can solve the problems of high consumption of personnel, high labor intensity and low work efficiency, and achieve the effects of improving work efficiency, reducing consumption and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

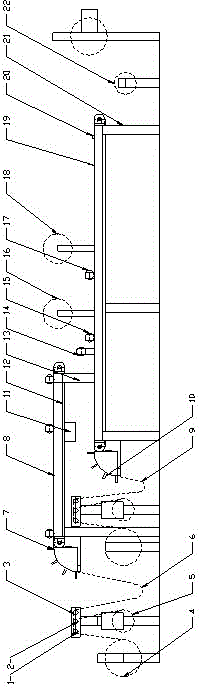

[0021] Such as figure 1 From the schematic diagram shown, it can be known that the nylon cloth automatic bonding system of the present invention includes a nylon cloth guiding device, a conveying device, a bonding device, a glue guiding and collecting device, and a coiling device.

[0022] There are two nylon-wrapped opening devices, which are nylon-wrapped opening device A and nylon-wrapped opening device B, and there are two transmission devices, which are transmission device A and transmission device B.

[0023] The nylon cloth unwinding device A, the nylon cloth unwinding device B, the conveying device B and the take-up device are distributed in sequence, the conveying device B is located at the upper end of the nylon cloth unwinding device B, the laminating device and the laminated glue unwinding and collecting device They are arranged on the upper end of the conveying device B sequentially along the conveying direction of the material.

[0024] Nylon cloth guide device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com