Automatic shearing machine for pine branches of plastic Christmas tree

A Christmas tree and shearing machine technology, applied in metal processing and other directions, can solve the problems of low manual shearing efficiency, increased difficulty of automatic shearing, and inability to adapt to mass production, etc., to achieve high shearing efficiency, good shearing quality, and satisfying high volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

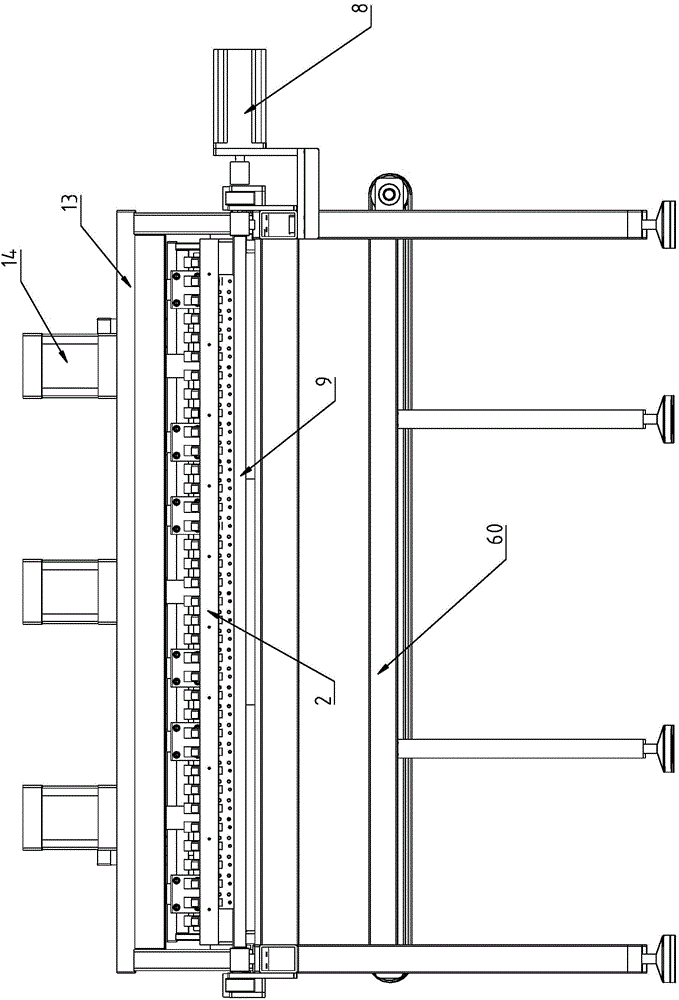

[0033] The structure of the plastic Christmas tree pine automatic shearing machine of the embodiment of the present invention is as Figure 1 to Figure 12 As shown, it includes a frame 1, a feeding mechanism, a pulling mechanism, a cutting mechanism, a conveyor belt and a control circuit. Feeding mechanism, material pulling mechanism and material cutting mechanism are installed on the top of frame 1.

[0034] The control circuit includes a control box, a PLC controller and a detection device.

[0035] The material pulling mechanism includes a material pulling plate 2, two linear guide rails 3, a material pulling plate driving device and 36 clamps. The sliders 302 of the linear guide rail 3 are respectively fixed on both sides of the pulling plate 2 , and the tracks 301 of the two linear guide rails 3 are fixed on both sides of the frame 1 in the transverse direction. 36 fixtures are arranged laterally along the frame 1 and installed on the puller plate 2 .

[0036] Each set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com