Six-DOF (Degree Of Freedom) planar joint robot

A technology of planar joints and degrees of freedom, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

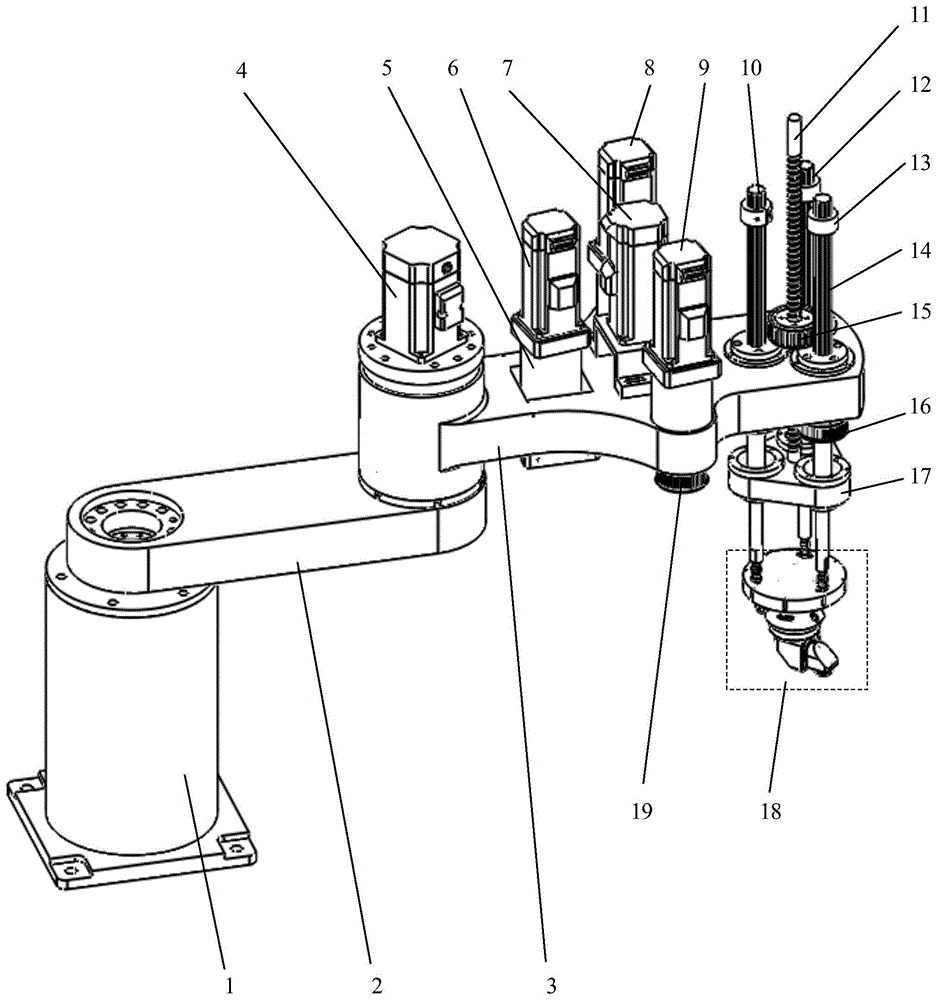

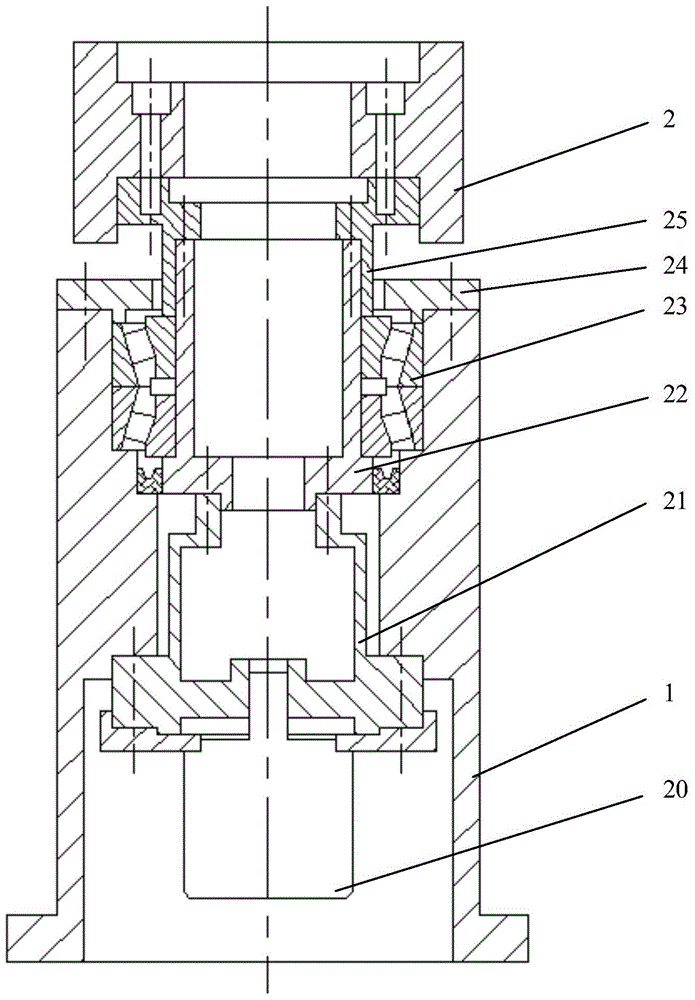

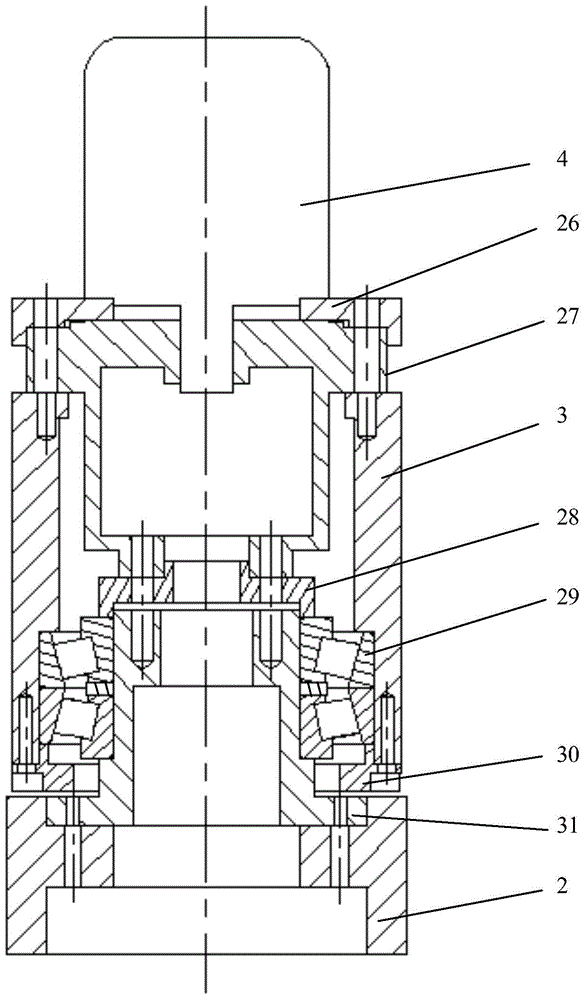

[0019] Such as figure 1 As shown, a six-degree-of-freedom planar joint robot provided by the present invention includes three parts: a base 1, a first arm 2 and its driving device, a second arm 3 and its driving device, and a three-degree-of-freedom wrist 18 and its driving device. The first arm 2 is installed on the base 1, the second arm 3 is installed at the end of the first arm, the three-degree-of-freedom wrist 18 at the end is connected with three ball splines (the first ball spline 10, the second ball spline 12, The third ball spline 14) is connected, and is driven by the driving device (the first servo motor 6, the second servo motor 8, the third servo motor 9) installed on the second arm through the synchronous pulley and the ball spline; The movement in the vertical direction of the wrist is provided by a ball screw 11, and the sixth servo motor 7 is powered by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com