Movable step type located mold

A step-type, mold technology, used in positioning devices, forming tools, manufacturing tools, etc., can solve problems such as unsmooth stripping, deformation of positioning holes, and blocking of blanks, so as to achieve smooth stripping, avoid friction, and produce low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

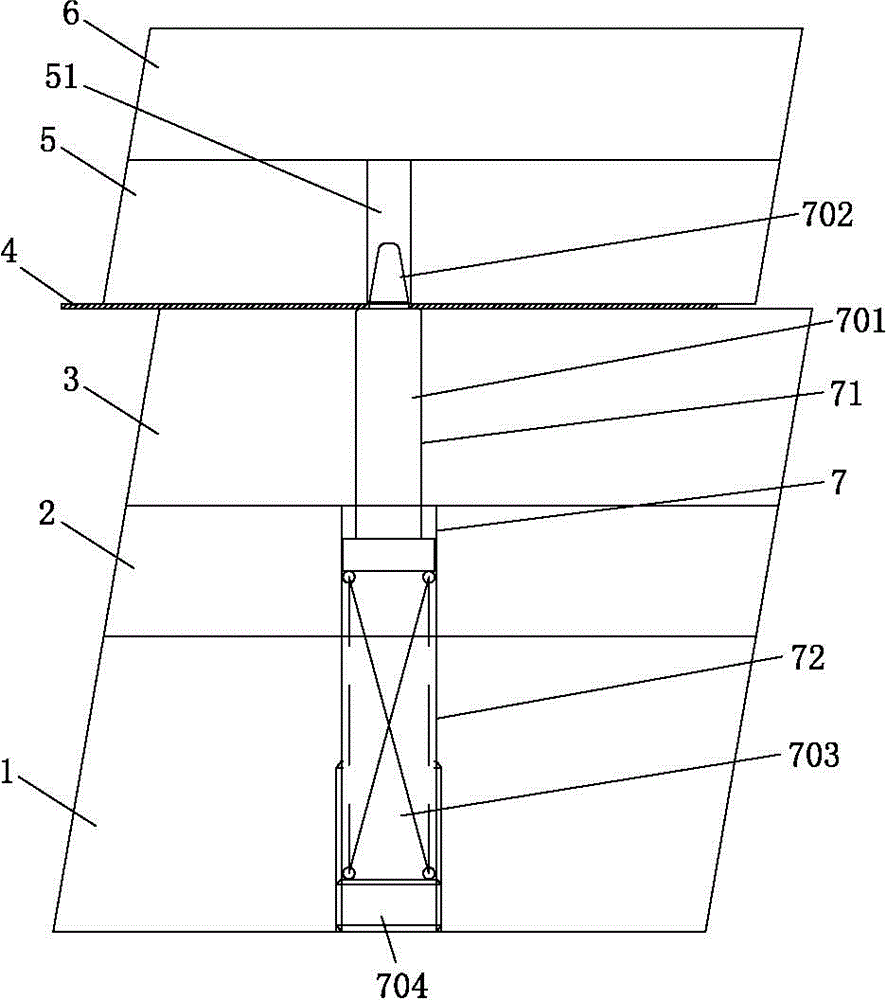

[0035] Embodiment 2 of a movable stepped positioning mold of the present invention, the difference between this embodiment and Embodiment 1 is that in this embodiment, the number of positioning and ejection mechanisms 7 is set to two, and the tablet 4 is set There are two positioning holes, and the bosses 702 of the two positioning ejection mechanisms 7 are respectively sleeved in the corresponding two positioning holes. The two positioning and ejecting mechanisms 7 drive the tablet 4 to move at the same time, which can make the tablet 4 stable and smooth during the stripping process. Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

[0036] Example 3 。

Embodiment 3

[0037] Embodiment 3 of a movable stepped positioning mold of the present invention, the difference between this embodiment and Embodiment 1 is that in this embodiment, the number of positioning and ejection mechanisms 7 is set to four, and the blank 4 is set to There are four positioning holes, and the bosses 702 of the four positioning ejection mechanisms 7 are respectively sleeved in the corresponding four positioning holes. The four positioning and ejecting mechanisms 7 drive the tablet 4 to move at the same time, which can make the stripping process of the tablet 4 more stable and smoother. Other structures and working principles of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com