Wholly mechanized integrated cultivation method for Chinese little greens

A technology of whole-process mechanization and cultivation method, which is applied in the field of whole-process mechanization supporting cultivation, can solve the problems of increased labor cost, low production efficiency, and rising production cost of chicken feathers, so as to reduce the use of herbicides, ensure product quality and safety, and improve soil. Effects of physicochemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

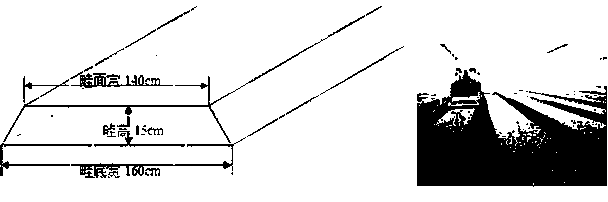

[0013] The specific implementation steps of the supporting cultivation method for the whole mechanized production of feather vegetable are as follows: (1) Seed screening: Before sowing, the prepared seeds are screened on a gravity screening machine to remove shriveled grains and impurities, so that the purity of the seeds is ≥ 98%, and the clarity is ≥ 98%. Germination rate ≥ 95%; ⑵Mechanical fertilization: use a 205-type tractor equipped with a fertilizer applicator to spread potassium sulfate compound fertilizer (15:15:15) and urea before planting, and the tractor starts from the left or right side of the shed when fertilizing Spread fertilization to ensure uniform fertilization, apply 40kg of potassium sulfate compound fertilizer per mu, and spray urea with a backpack duster before and after the chicken feathers are sealed, about 15.0 kg per mu; , when the soil moisture content is about 40%, use Kubota M954 equipped with a rotary plow to plow the soil to a depth of 28 cm; A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com