Automatic coiling mechanism for stator winding

A stator winding and lead wire technology, which is applied in the field of stator winding lead wire automatic nesting mechanism, can solve problems such as poor working environment, low production efficiency, and high labor intensity, and achieve the effects of improving production efficiency, reducing labor force, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

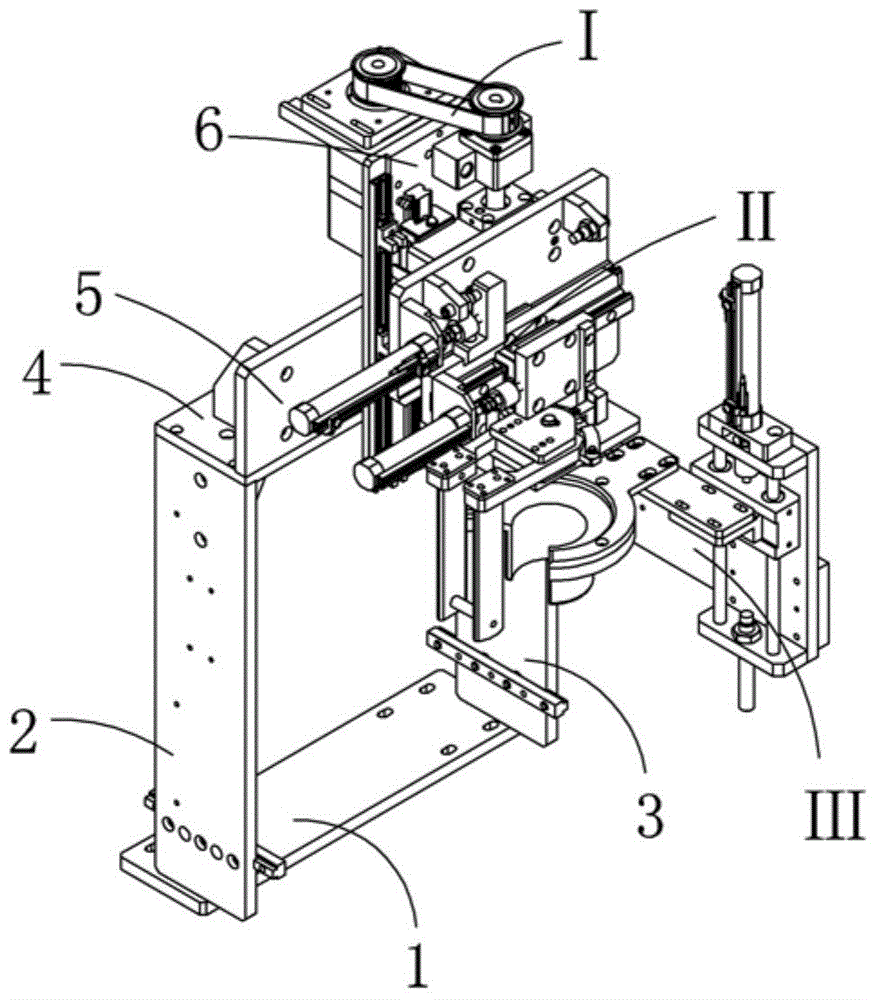

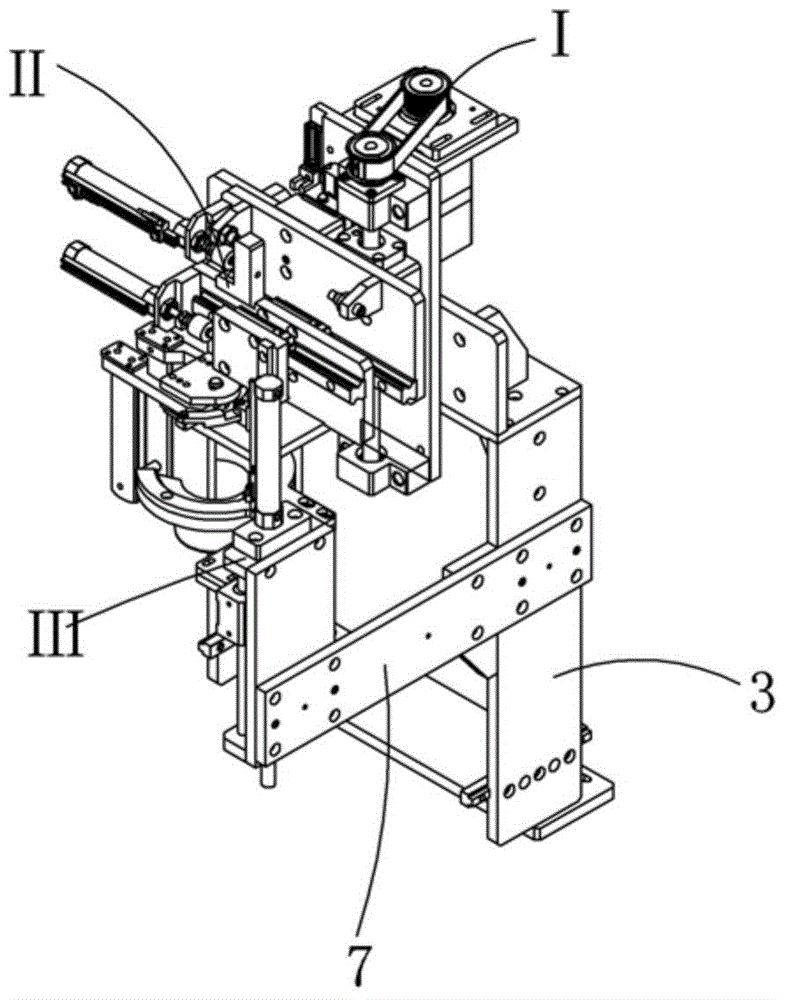

[0030] Examples, see attached Figure 1-10 , a stator winding lead wire automatic nest wire mechanism, which includes a bottom plate 1, a lifting and fixing plate 4 is installed on the bottom plate through left and right side plates 2 and 3, and a lifting and fixing plate 5 is vertically installed on the front side of the lifting and fixing plate, And between the lifting fixed plate and the lifting mounting plate, the lifting ribs are used to strengthen and fix; the lifting mounting plate is equipped with a fixed vertical plate 6, and the lifting mechanism I is installed on the fixed vertical plate, and the lifting slider of the lifting mechanism is installed There is a lead wire guiding mechanism II; a mounting plate 7 is mounted on the right side plate, and a stator winding protection mechanism III is mounted on the mounting plate.

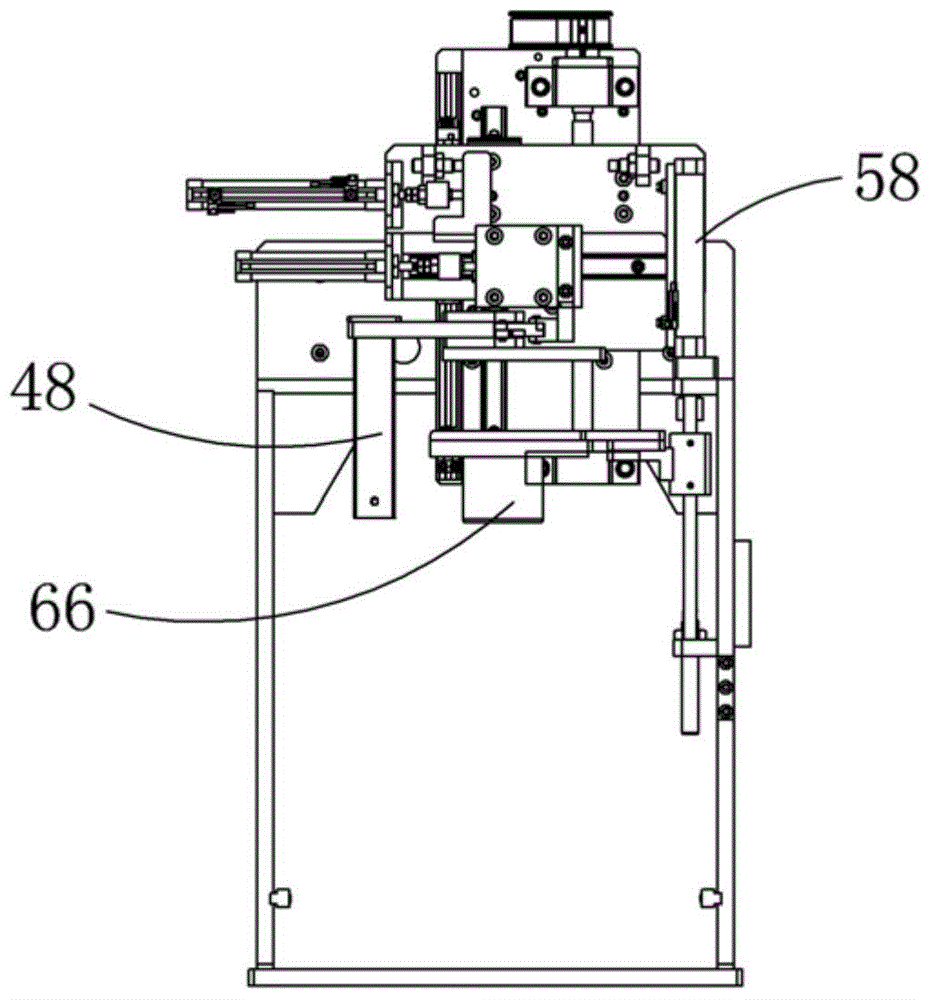

[0031] The lift motor support 8 of the lifting mechanism is installed on the upper rear side of the fixed vertical plate, the lift motor mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com