Drawing method of main busbar connection diagram between dry-type distribution transformer and low-voltage switchgear

A technology for distribution transformers and low-voltage switchgears, which is applied in the field of drawing main bus connection diagrams between dry-type distribution transformers and low-voltage switchgears, and can solve problems such as high probability of errors, long connection diagram cycle, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

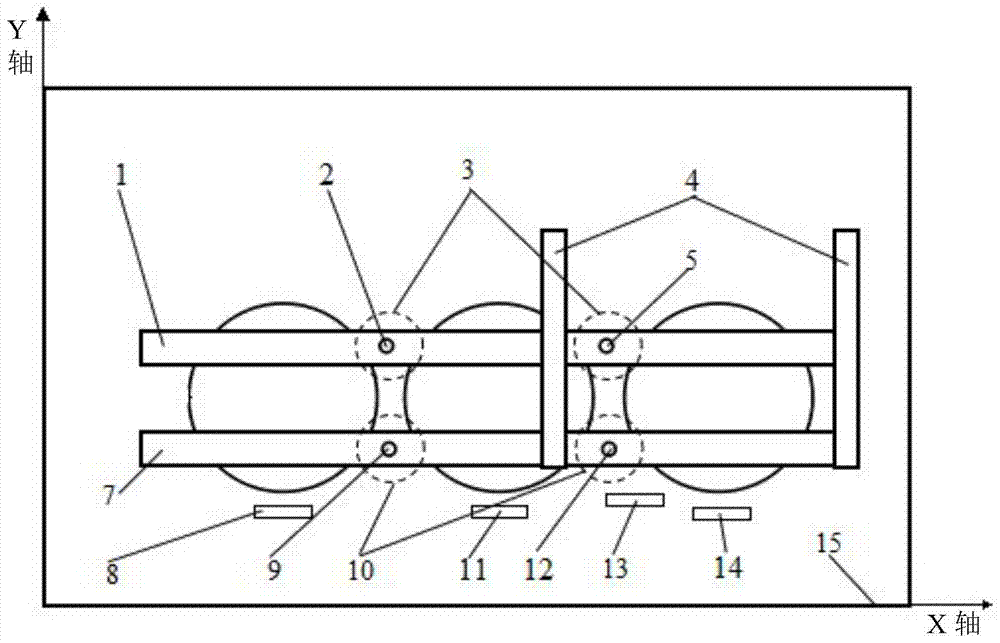

[0161] In this embodiment, dry-type distribution transformers adopt 1000KVA, 10KV / 0.4KV dry-type cast resin distribution transformers, the low-voltage side voltage is 400V, and the radii of the first rejection zone and the second rejection zone are both 50mm.

[0162] In this embodiment, the drawing method of the main busbar connection diagram between the dry-type distribution transformer and the low-voltage switchgear, the specific steps are as follows:

[0163] The first step is to establish the XY coordinate system of the dry-type distribution transformer in the dry-type distribution transformer cabinet 15:

[0164] Place the dry-type distribution transformer in the dry-type distribution transformer cabinet 15. From the top view of the dry-type distribution transformer cabinet, the lower vertex on the side close to the c-phase copper bar 8 on the low-voltage side of the dry-type distribution transformer is defined as The origin of the coordinates, the horizontal direction o...

Embodiment 2

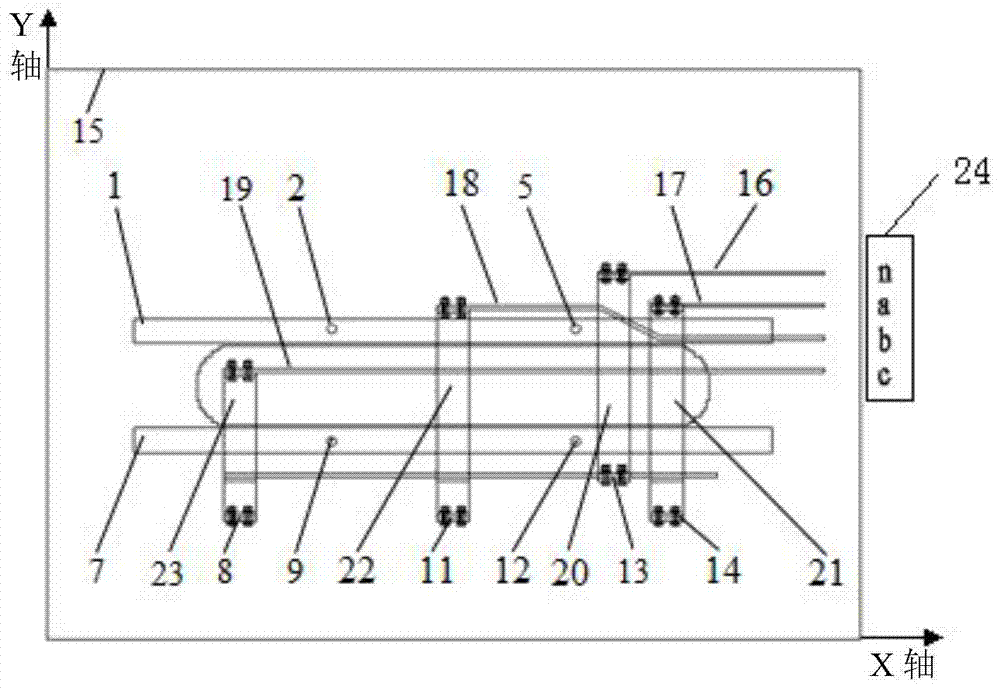

[0189] Except for the following differences from Embodiment 1, the drawing method of the main busbar connection diagram between other dry-type distribution transformers and low-voltage switchgear is the same as Embodiment 1:

[0190] In this embodiment, the dry-type distribution transformer adopts 1600KVA, 10KV / 0.4KV dry-type resin cast distribution transformer, and the outlet mode of the input copper bar 24 of the low-voltage switchgear is selected as the left outlet, and the input copper bar 24 of the low-voltage switchgear is in the negative direction of the Y axis. The phase sequence on is abcn;

[0191] From the top view coordinate diagram of dry-type distribution transformer (see image 3 ), the coordinate origin is set at the lower left corner of the dry-type distribution transformer cabinet 15, the X positive semi-axis is horizontally to the right, and the Y positive semi-axis is vertically upward (that is, the dry-type distribution transformer is directed from the low...

Embodiment 3

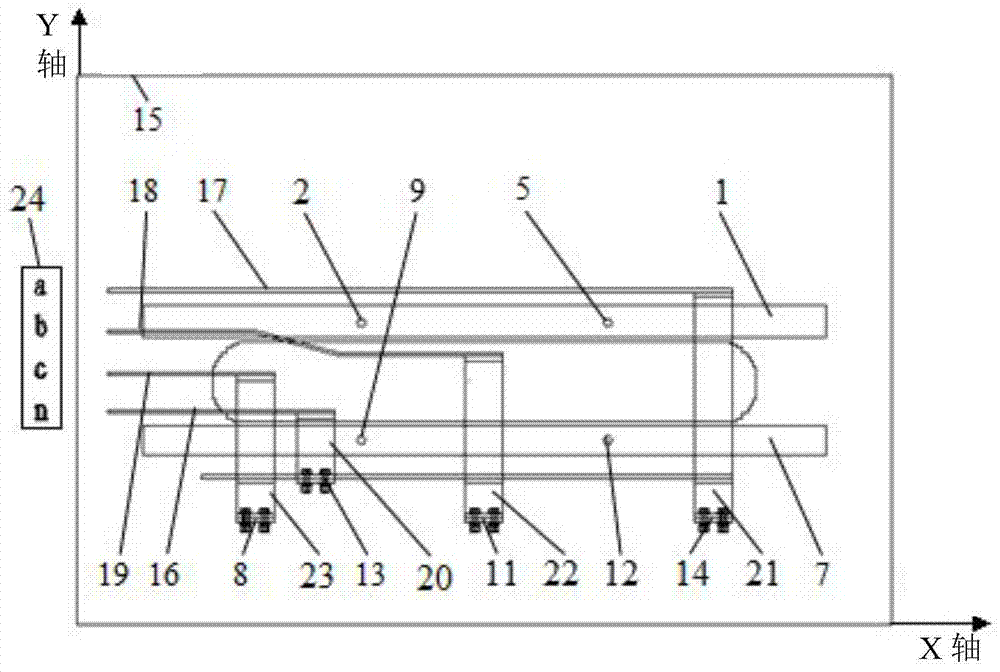

[0206] Except for the following differences from Embodiment 1, the drawing method of the main busbar connection diagram between other dry-type distribution transformers and low-voltage switchgear is the same as Embodiment 1:

[0207] The phase sequence of the input copper bar 24 of the low-voltage switchgear in the negative direction of the Y axis is cban.

[0208] Draw the copper bars of each connected line:

[0209] B-1. Determine the position and shape of the copper bar connected to line c:

[0210] The Y-axis coordinate of the c-phase copper bar of the input copper bar 24 of the low-voltage switchgear is not within the Y-axis coordinate range of the two rejection areas, and the copper bar of the c-connected line is a straight copper bar; the coordinates of the starting point of the copper bar of the c-connected line are the low-voltage switchgear Input the coordinates ptc(x 24c ,y 24c ), the X-axis coordinate of the end point of the copper bar of the c-connected line is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com