Full-automatic rock point load test instrument

A point load, fully automatic technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of rock shot injury by testers, complex structure of measuring system equipment, and rock easily ejected under pressure. Reduce the labor intensity of the test, realize the automatic load parameter measurement, and reduce the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

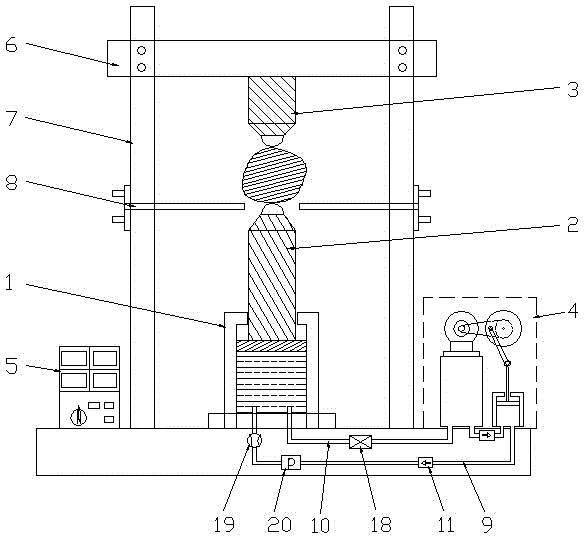

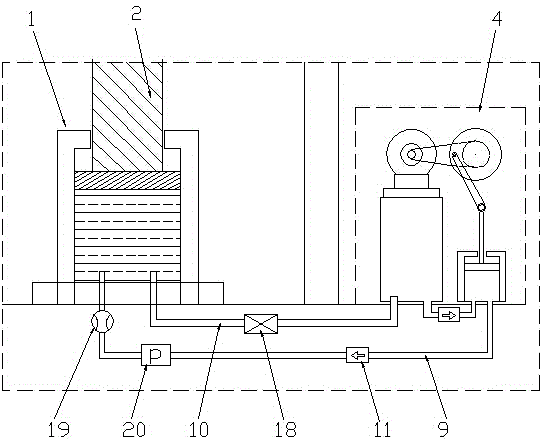

[0024] Further illustrate the implementation of the present invention with reference to the accompanying drawings (as shown in Figure 1, figure 2 , image 3 , Figure 4 , Figure 5 shown):

[0025]A fully automatic rock point load tester, including a loading system and a measuring system, the loading system includes a hydraulic jack 1, a movable hydraulic loading cone 2, a fixed loading cone 3, an electrohydraulic device 4, a load support beam 6 and a load The bracket 7; the hydraulic cylinder of the hydraulic jack 1 communicates with the electrohydraulic device 4 through the pressure hydraulic pipe 9 and the pressure discharge hydraulic pipe 10; the movable hydraulic loading cone 2 is fixed above the piston of the hydraulic jack 1, and the fixed loading cone 3 is fixed On the load support beam 6, the movable hydraulic loading cone 2 and the fixed loading cone 3 have the same center line, and the load support beam 6 is fixedly installed on the load support 7; the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com