Drying device, refrigerator and desiccant recovery method

A drying device and desiccant technology, applied in the direction of separation methods, household refrigeration devices, chemical instruments and methods, etc., can solve the problems of inability to control accurately and effectively, short service life, cumbersome operation, etc., and achieve convenient control and improvement Efficiency, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

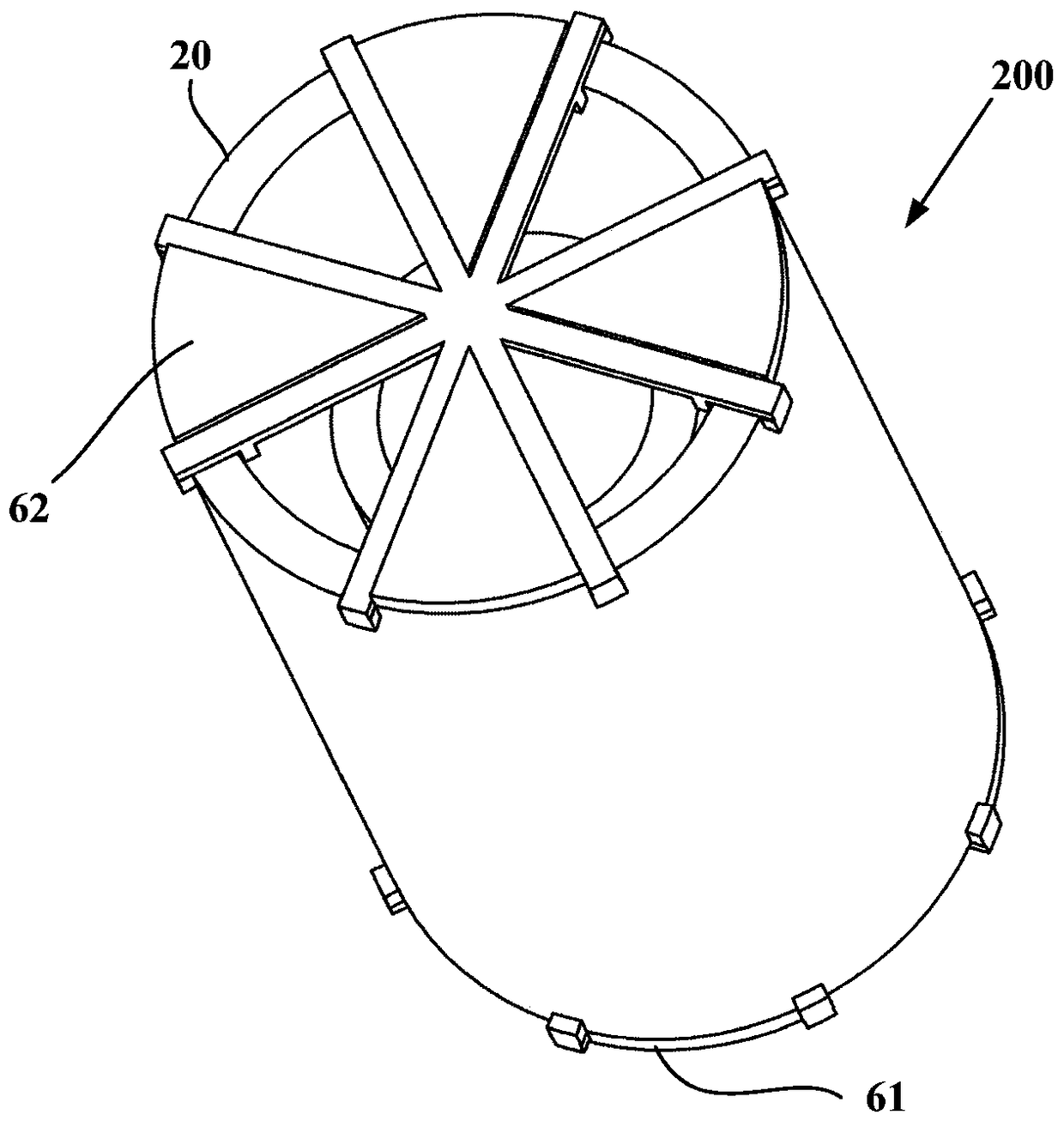

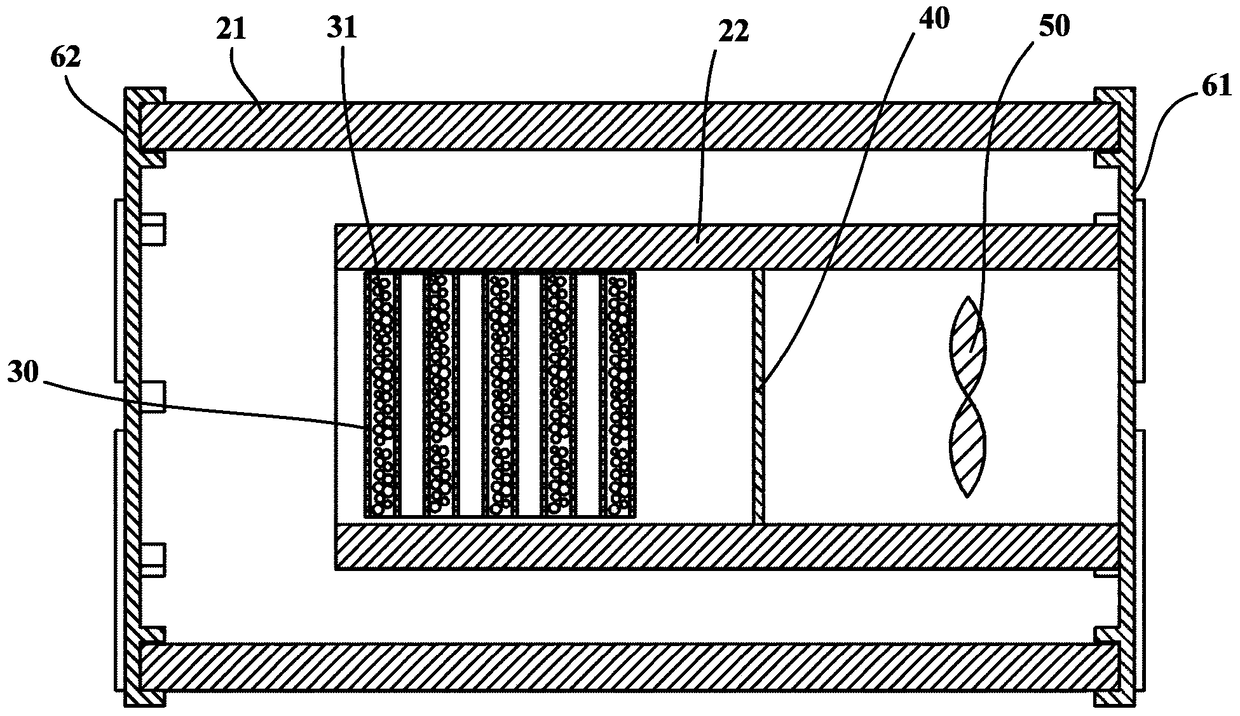

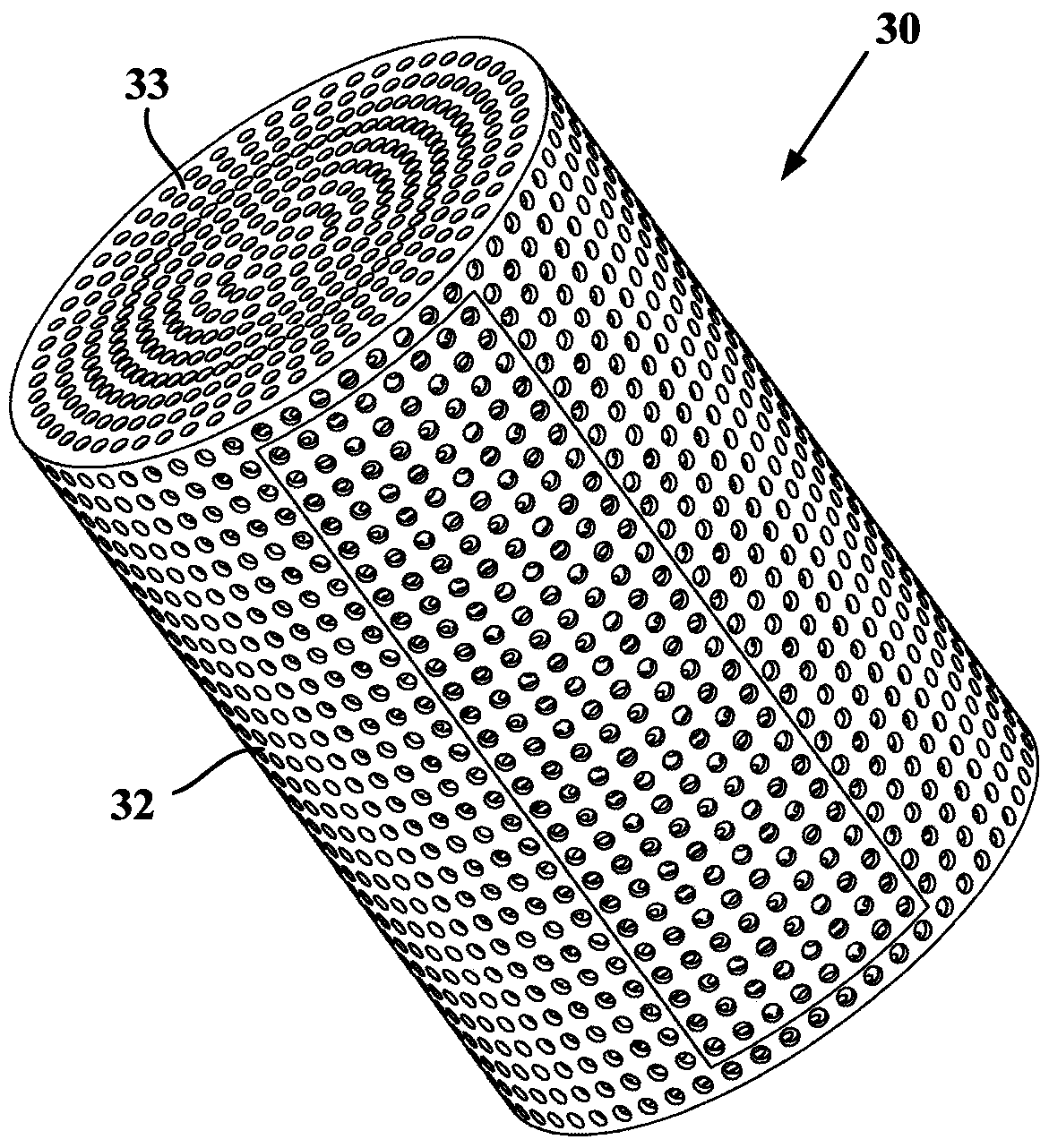

[0042] figure 1 is a schematic structural diagram of a drying device according to an embodiment of the present invention. Such as figure 1 shown, and refer to figure 2 , the embodiment of the present invention provides a drying device 200 for a refrigerator drying room. The drying device 200 may include a device body 20 and a drying part 30 containing a desiccant 31 . The device body 20 has an airflow inlet and a dry airflow outlet communicated with the interior of the drying chamber 110 in a controlled manner. The drying unit 30 can be installed in the device body 20 and is configured to dry the gas entering the device body 20 through the gas flow inlet, and the dried gas flows out of the drying device 200 through the dry gas flow outlet. For example, when it is detected that the humidity inside the drying chamber 110 is higher than the first preset value, the gas inside the drying chamber 110 is allowed to enter the interior of the device body 20, and after being dried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com