Refrigerated oil recovery device and method

A technology of recovery device and refrigeration oil, applied in the direction of liquid variable volume machinery, variable volume pump components, machines/engines, etc., can solve the problems of non-reusable, block the oil circuit, waste refrigeration oil, etc., and achieve automatic control , The effect of preventing secondary mixing and saving factory costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical solution of the present invention more clear, the refrigerating oil recovery device and method of the present invention will be further described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention and not to limit the present invention.

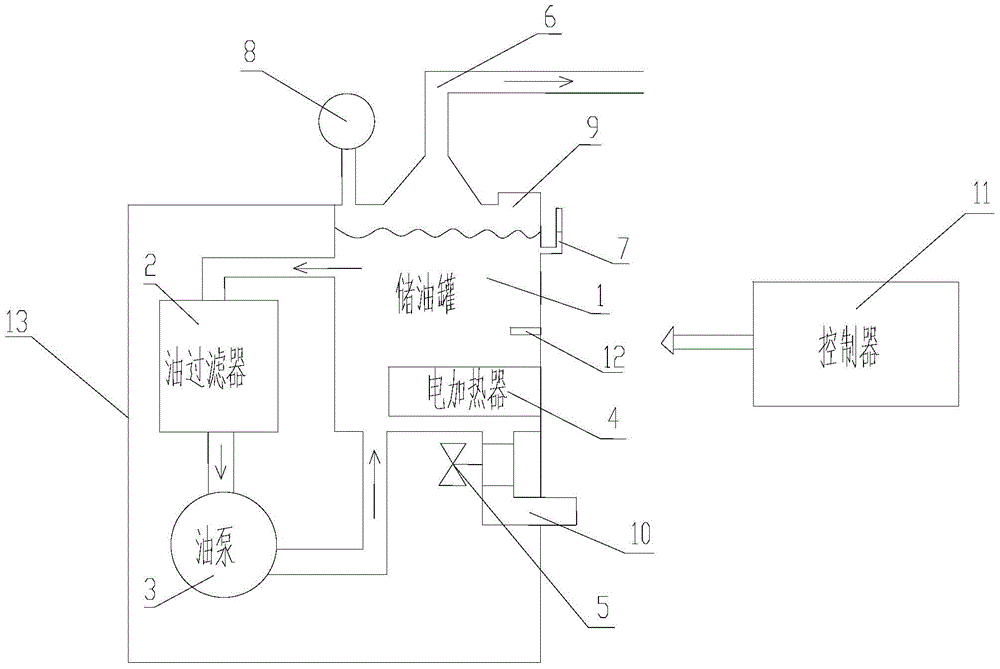

[0030] like figure 1 Shown is a schematic structural view of an embodiment of the refrigeration oil recovery device of the present invention, including an oil storage tank 1, an oil filter 2, an oil pump 3, an electric heater 4, an electronic valve 5, a vacuuming device 6, and an oil level sight glass 7 , pressure gauge 8, second inlet 9, second outlet 10, controller 11, temperature sensor 12 and outer casing 13.

[0031] Wherein, the material of the outer casing 13 is iron sheet, and in other embodiments, the outer casing 13 can also be made of other materials. Preferably, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com