Construction material feeding and conveying method for slope construction

A technology for slopes during construction, applied in construction, infrastructure engineering, etc., can solve problems such as complex structure, troublesome installation, safety hazards in lifting and lowering cement buckets, etc., and achieve the effect of easy reinforcement, low cost, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

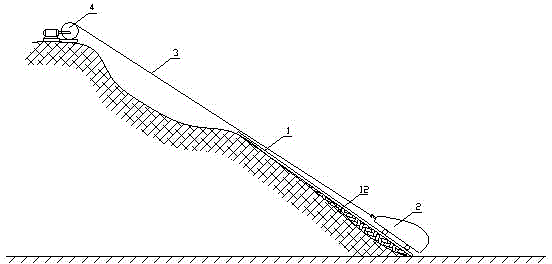

[0013] First of all, at the site of slope construction, select a suitable location for installing the slideway, and clean up debris and weeds;

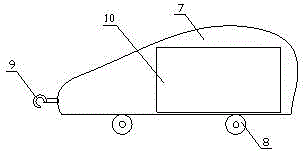

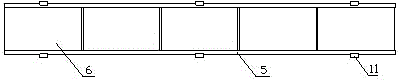

[0014] Then make as figure 2 shown slides and figure 2 The feeding chute shown: The slideway is made of two steel pipes with a diameter of φ48mm and a connecting steel plate with a thickness of 3mm, which are commonly used in ordinary scaffolding. The two ends of the connecting plate are welded on the two steel pipes to form a slideway; The material slide bucket is composed of a bucket box, rollers and pull hooks. The bottom of the bucket box is divided into front and rear groups and installed with 4 concave rollers. There are side doors that can be opened and closed on both sides to facilitate unloading; the upward end of the bucket box is fixed with a pull hook;

[0015] Use universal fasteners to fix the slideway on the slope surface, and place supports in the gaps to ensure stable installation and prevent bending deformation du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com