Washing machine control method and washing machine

A control method and washing machine technology, which are applied in the control device of washing machine, other washing machines, water treatment parameter control, etc., can solve problems such as secondary pollution of clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

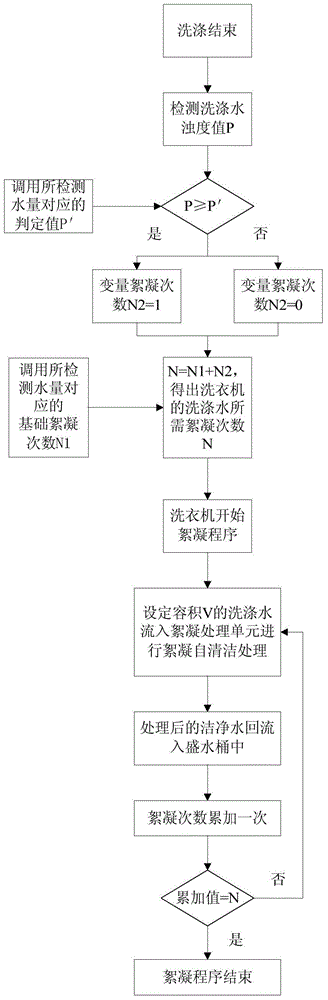

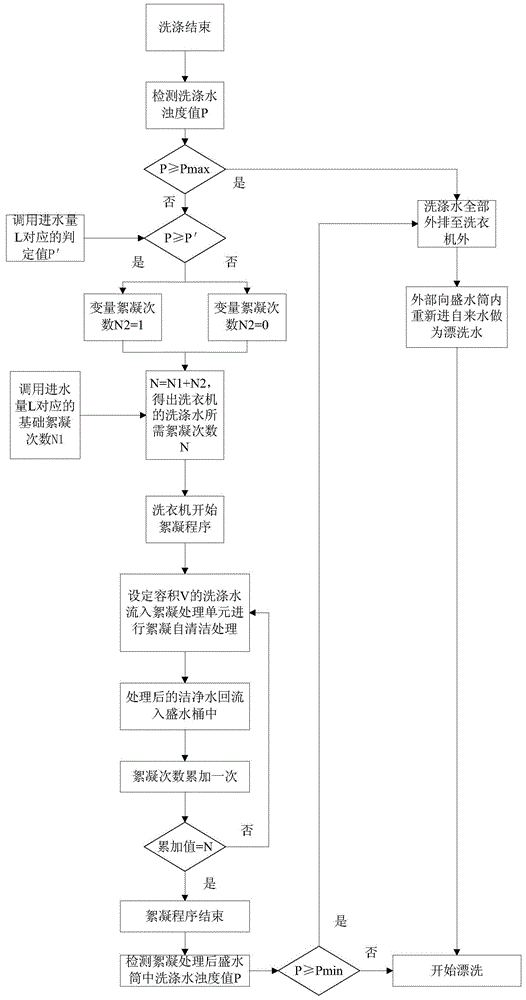

[0076] Such as figure 2 As shown, in this embodiment, after the washing process of the washing machine is completed, the first turbidity sensor provided on the water storage tub detects the turbidity of the washing water in the water storage tub to obtain the turbidity value P of the washing water. The washing water turbidity value P obtained by the above detection is compared with the maximum turbidity value Pmax.

[0077] When the washing water turbidity value P

[0078] When the washing water turbidity value P≥the highest setting value Pmax, the washing machine executes the normal rinsing procedure: all the washing water in the water tank is drained out of the washing machine, and the washing machine uses the external normal water as...

Embodiment 2

[0081] Such as figure 2 As shown, in this embodiment, after the flocculation procedure of the washing machine is completed, the first turbidity sensor installed on the water storage cylinder detects the turbidity of the washing water in the water storage cylinder to obtain the turbidity of the washing water after the flocculation self-cleaning is completed. Value P. The washing water turbidity value P obtained by the above detection is compared with the rinse set value Pmin.

[0082] When the washing water turbidity value P

[0083] When the washing water turbidity value P≥rinsing set value Pmin, the washing machine will follow the normal rinsing procedure: all the washing water in the water tank will be drained out of the washing machine, and the washing machine will use the external normal water as the rinsing wa...

Embodiment 3

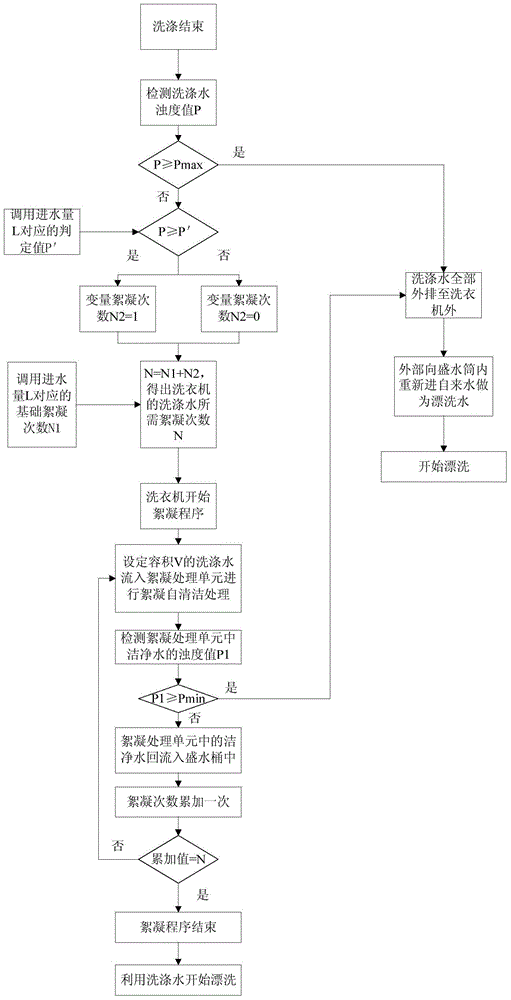

[0086] Such as image 3 As shown, in this embodiment, the specific steps of the washing machine control method are as follows:

[0087] 21) After the washing machine is finished washing, use the first turbidity sensor to detect the turbidity of the washing water in the water tank to obtain the turbidity value P of the washing water;

[0088] 22) Compare the turbidity value P of the washing water with the maximum setting value Pmax; if P≥Pmax, the washing machine enters the normal rinsing procedure, all the washing water is drained out, and tap water is re-introduced from the outside as rinsing water to rinse the clothes , after rinsing, drain the water, spin dry, and finish the laundry; if P<Pmax, go to step 23);

[0089] 23) According to the inflow L of the washing water used in the washing machine washing program, call the turbidity judgment value P′ corresponding to the inflow L of the washing water, the number of basic flocculation cycles N1 and the washing in the floccul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com