Nanometer microemulsion cleanup additive

A technology of nano-microemulsion and drainage aid, which is applied in the direction of production fluid, wellbore/well components, drilling composition, etc., to achieve the effect of improving the effect of fracturing reconstruction, good liquid flowback effect, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

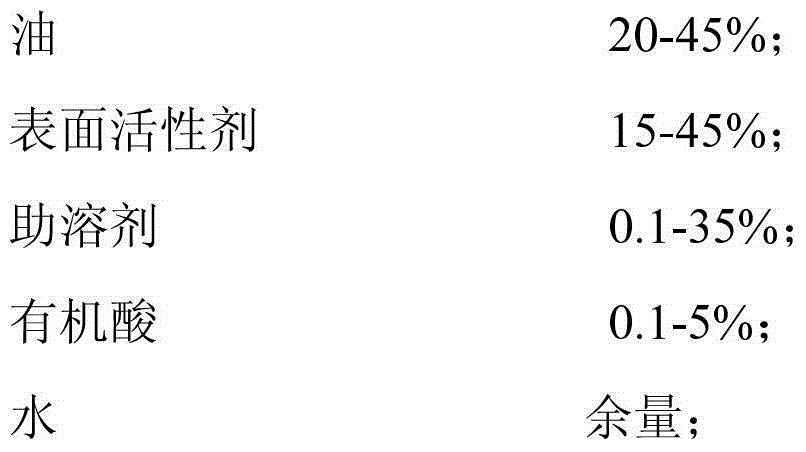

[0029] This embodiment provides a nano-microemulsion drainage aid, its concentrated solution is made up of the following raw materials, in percent by weight: 31.3% of amino silicone oil with an amino value of 0.4 and a viscosity of 1000 cps, nonionic surfactant isomerization ten Triol polyoxypropylene (4) polyoxyethylene (6) ether 17.4%, ethylene glycol monobutyl ether 1%, glacial acetic acid 2.8%, water 47.5%.

[0030] The nano microemulsion drainage aid of the present embodiment is prepared by the following method:

[0031] Step 1, mix amino silicone oil, nonionic surfactant isomeric tridecyl alcohol polyoxypropylene (4) polyoxyethylene (6) ether, ethylene glycol monobutyl ether, glacial acetic acid and water to make nano microemulsion The concentrated solution of the drainage aid is an O / W microemulsion with a solid content of 48.7%.

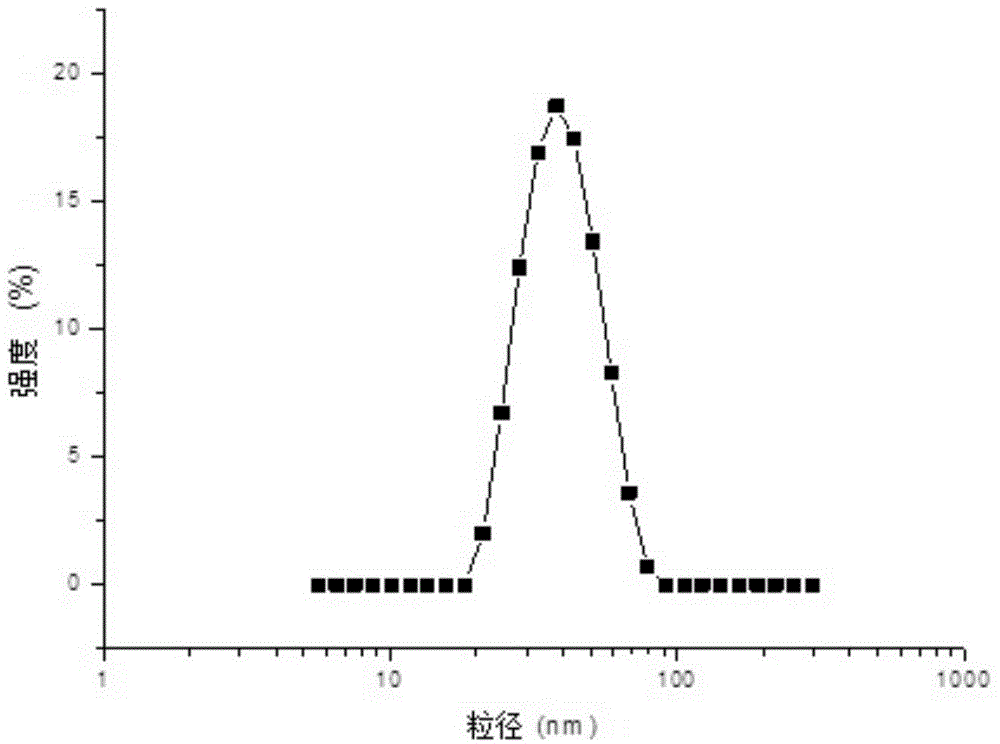

[0032] Step 2, dilute the concentrated microemulsion with an aqueous solution of 2wt%KCl with a concentration of 0.2wt% to obtain a uniform...

Embodiment 2

[0037] The present embodiment provides a kind of nano microemulsion drainage aid, and its concentrate is made up of the following raw materials, by weight percentage: Amino silicone oil 10% with an amino value of 0.4 and a viscosity of 800cps, 20% of D-limonene, non-ionic Surfactant isotridecyl alcohol polyoxypropylene (4) polyoxyethylene (6) ether 22%, glacial acetic acid 1%, butanol 7%, water 40%.

[0038] The nano microemulsion drainage aid of the present embodiment is prepared by the following method:

[0039] Step 1, mix amino silicone oil, D-limonene, non-ionic surfactant isotridecyl alcohol polyoxypropylene (4) polyoxyethylene (6) ether, glacial acetic acid, butanol and water to make a nano-microemulsion Concentrates of drainage aids.

[0040] Step 2, dilute the concentrated microemulsion with a KCl aqueous solution with a concentration of 2wt%, and the content of the concentrated solution is 0.2wt%, to obtain a uniform transparent, light blue nano-microemulsion draina...

Embodiment 3

[0053] The present embodiment provides a nano-microemulsion drainage aid, and its concentrated solution is made up of the following raw materials, in percent by weight: 5% of amino silicone oil with an amino value of 0.4 and a viscosity of 800 cps, 25% of fatty acid methyl ester, non-ionic Surfactant isomeric tridecyl alcohol polyoxypropylene (4) polyoxyethylene (6) ether 20%, lauryl amine oxide 10%, glacial acetic acid 1%, ethylene glycol monobutyl ether 11%, water 28% .

[0054] The nano microemulsion drainage aid of the present embodiment is prepared by the following method:

[0055] Step 1, amino silicone oil, fatty acid methyl ester, non-ionic surfactant isomeric tridecyl alcohol polyoxypropylene (4) polyoxyethylene (6) ether, lauryl amine oxide, glacial acetic acid, ethylene glycol monobutyl Ether is mixed with water to make a concentrated solution of nano-microemulsion drainage aid.

[0056] Step 2, dilute the concentrated microemulsion with a KCl aqueous solution wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com