Multi-phase flow dynamic membrane microbial carrier filler

A microbial carrier and multi-phase flow technology, applied in the field of multi-phase flow dynamic film microbial carrier filler, can solve the problems of soft material, low packing strength, and ineffective effects, etc., and achieve the effect of shortening the film-hanging time and strong flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

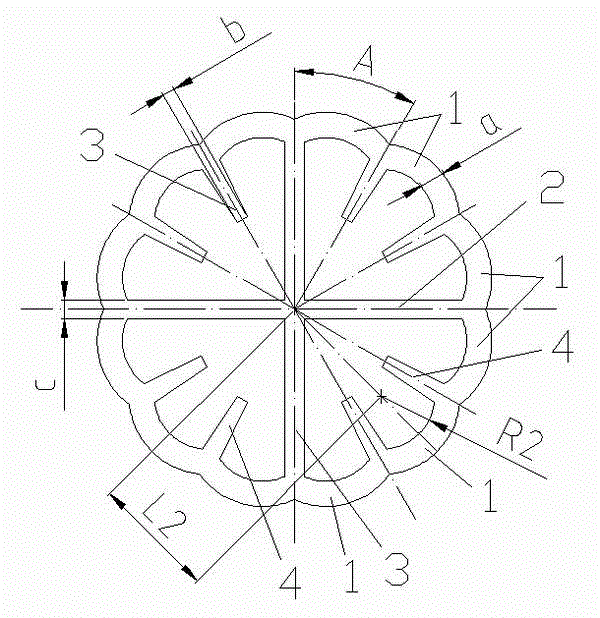

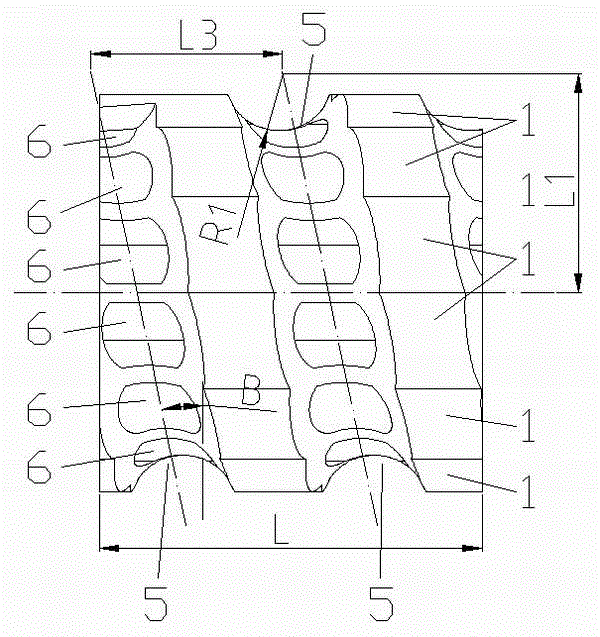

[0009] figure 1 , 2 A structural diagram of a multiphase flow dynamic membrane microbial carrier filler is shown. In the figure, the multi-phase flow dynamic membrane microbial carrier filler adopts high-density polyethylene as the main material, calcium carbonate and starch as auxiliary materials, and is formed by die-casting. The carrier filler is a thin-walled tubular structure composed of 12 uniformly arranged convex arcs 1 connected end to end. In the thin-walled tubular structure, there are transverse ribs 2 and longitudinal ribs 3 at an angle of 90 degrees to each other. The transverse ribs 2 and Both ends of the longitudinal reinforcing rib 3 are respectively connected to the intersection of two convex arcs 1 on the inner wall of the thin-walled tubular structure, and inner ribs 4 are provided at the intersection of the remaining two convex arcs 1 on the inner wall of the thin-walled tubular structure , a spiral groove 5 is provided on the outer wall of the thin-wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com