The detection and feeding mechanism of the automatic full inspection machine for pipe fittings

A pipe fitting and automatic technology, applied in the direction of conveyor objects, transportation and packaging, sorting, etc., can solve problems such as lack, achieve the effect of improving accuracy, improving efficiency and accurate performance, and facilitating detection and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

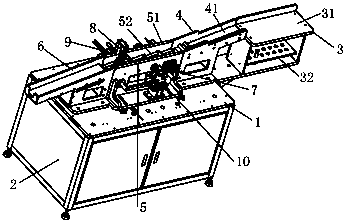

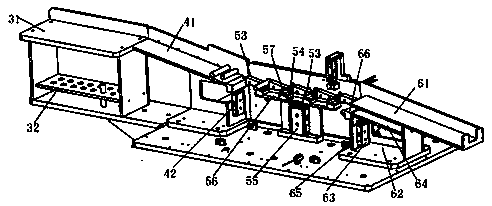

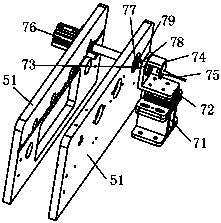

[0013] Combine below Figure 1 to Figure 6 Specific description embodiment:

[0014] Such as Figure 1 to Figure 6 As shown, the automatic full inspection machine for automobile airbag tubes includes a frame 1, and the bottom of the frame 1 is provided with an electrical distribution control box 2; the frame is provided with a workbench 3 and a feeding device 4 , detection device 5 and unloading device 6; Described workbench 3 comprises table top 31 and standard limited sample storage area 32; Described loading device 4 is a chute 41 that is arranged on the frame 1, and chute 41 The top of the top is connected with the table top 31, and the rear end of the chute 41 is provided with a material feeding and jacking cylinder 42; the detection device 5 includes a channel 52 composed of two splints 51, and the two splints 51 are correspondingly provided with detection holes 11, The detection hole 11 is in one-to-one correspondence with the first chamfering detection device 7, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com